Method and device for measuring refractive index of transparent medium based on Y-shaped-cavity orthogonal polarization laser

A technology of orthogonal polarization and transparent medium, applied in the direction of polarization influence characteristics, etc., can solve the problems of complex instrument structure, heavy operation work, low precision, etc., and achieve the effects of high response speed, high resolution and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

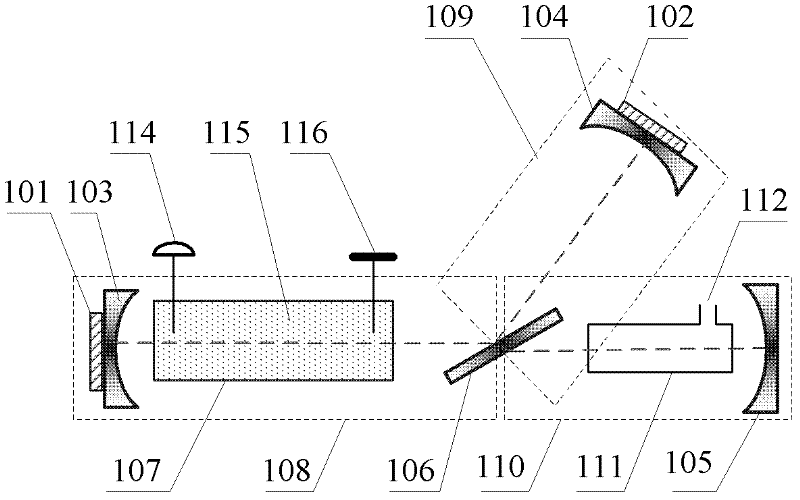

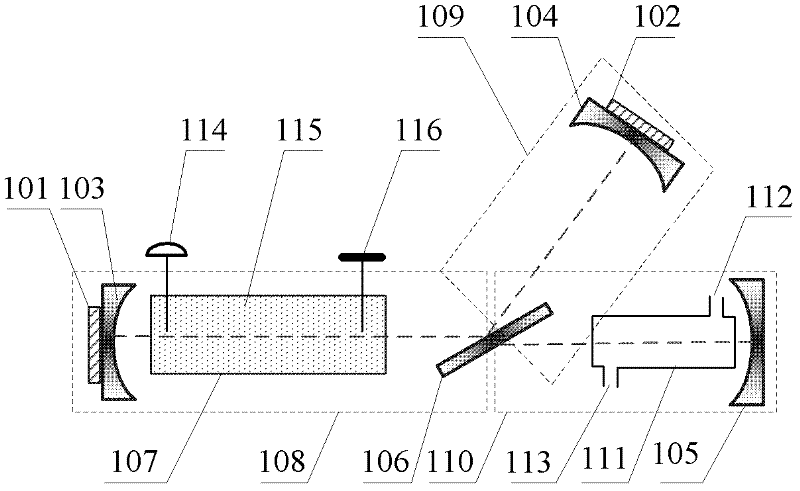

[0024] exist figure 1 Among them, the Y-cavity orthogonally polarized laser 100 includes a piezoelectric ceramic 101, a first high-reflectivity lens 103, a second high-reflectivity lens 104, a third high-reflectivity lens 105, a polarization splitting film 106, and a helium-neon discharge tube 107 , common section 108, S subsection 109 and P subsection 110.

[0025] The common segment 108 and the S sub-segment 109 are processed integrally using glass-ceramic material, and they share one end face. The first high-reflectivity lens 103 is pasted on the first end surface of the common section 108 by optical glue, and the first piezoelectric ceramic 101 is mounted on the first high-reflectivity lens. The second high-reflectivity mirror 104 is pasted on the first end surface of the S subsection 109 by means of optical glue. The second piezoelectric ceramic 102 is installed on the second high reflectivity mirror 104 . The polarization splitting film 106 is plated on the common end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com