Method for measuring vanadium content of silicon ferrovanadium

A technology of silicon vanadium iron and vanadium iron, which is applied in the field of determination of vanadium content of vanadium alloys, can solve the problems of difficult sample handling, unsuitable analysis, serious measurement interference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

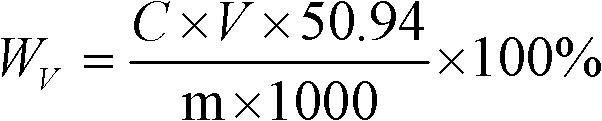

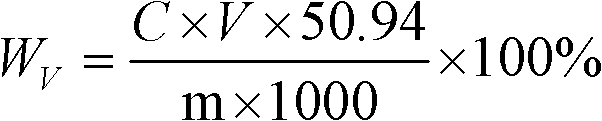

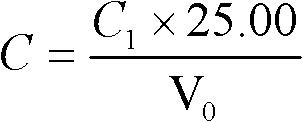

[0036] Take by weighing 0.20g (accurate to 0.0001g) ferrosilicon vanadium sample for test in polytetrafluoroethylene beaker (for synthetic standard sample, weigh a certain amount of vanadium standard sample and a certain amount of ferrosilicon standard sample as table 1 Synthetic standard sample), add 15mL concentration of 66% nitric acid, dropwise add concentration of 40% hydrofluoric acid 5mL, heat to dissolve the sample completely, add 6mL concentration of 98% sulfuric acid, heat to just smoke. Remove the Teflon beaker from the heating device, cool it, transfer the solution to a 500mL conical flask, add 10mL of 85% phosphoric acid, heat to smoke for 1 to 2 minutes, and remove the Teflon from the heating device Cool the beaker to room temperature, add 70mL of sulfuric acid with a concentration of 14%, shake well, cool to below 45°C, add potassium permanganate solution with a concentration of 40g / L until a stable red color appears, let it stand for 3min, add 10mL of sulfuric a...

example 2

[0048] Take by weighing 0.20g (accurate to 0.0001g) ferrosilicon vanadium sample for test in polytetrafluoroethylene beaker (for synthetic standard sample, take by weighing a certain amount of vanadium standard sample and a certain amount of ferrosilicon standard sample as table 2 Synthetic standard sample), add 12mL of nitric acid with a concentration of 60%, dropwise add 3mL of hydrofluoric acid with a concentration of 36%, heat to dissolve the sample completely, add 5.5mL of sulfuric acid with a concentration of 91%, and heat until just smoking . Remove the Teflon beaker from the heating device, cool it, transfer the solution to a 500mL conical flask, add 9mL of 80% phosphoric acid, heat to smoke for 1 to 2 minutes, remove the Teflon from the heating device Cool the beaker to room temperature, add 75mL of sulfuric acid with a concentration of 13%, shake well, cool down to below 45°C, add potassium permanganate solution with a concentration of 20g / L until a stable red color ...

example 3

[0056] Take by weighing 0.20g (accurate to 0.0001g) ferrosilicon-vanadium sample for test in polytetrafluoroethylene beaker (for synthetic standard sample, weigh a certain amount of vanadium-iron standard sample and a certain amount of ferrosilicon standard sample as table 3 Synthetic standard sample), add 20mL of nitric acid with a concentration of 68%, add 6mL of hydrofluoric acid with a concentration of 38% drop by drop, heat to dissolve the sample completely, add 6.5mL of sulfuric acid with a concentration of 95%, and heat until just smoking . Remove the Teflon beaker from the heating device, cool it down, transfer the solution to a 500mL conical flask, add 11mL of 82% phosphoric acid, heat to smoke for 1 to 2 minutes, remove the Teflon from the heating device Cool the beaker to room temperature, add 65mL of sulfuric acid with a concentration of 15%, shake well, cool to below 45°C, add potassium permanganate solution with a concentration of 50g / L until a stable red color a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com