Pipeline detection method and device through exciting axial guided waves by utilizing annular laser

A technology for pipeline detection and excitation axis, which is applied in the direction of optical testing for flaws/defects, etc. It can solve the problems that restrict the application and development of pipeline guided wave detection, the huge laser ultrasonic detection system, and the high requirements for the detection environment, so as to achieve small dispersion and low cost. Low, clear signal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] specific implementation plan

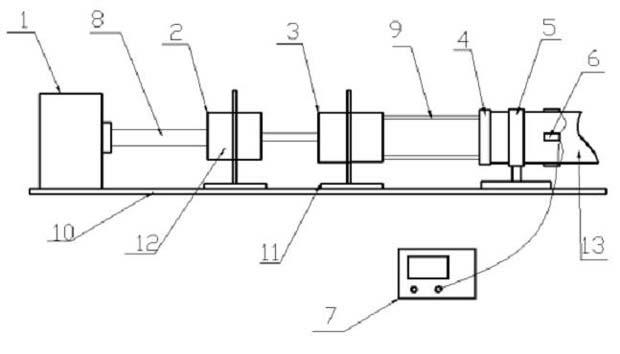

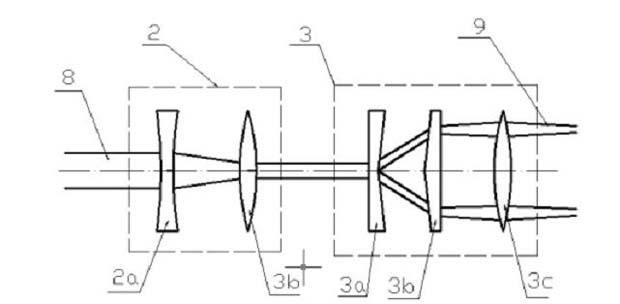

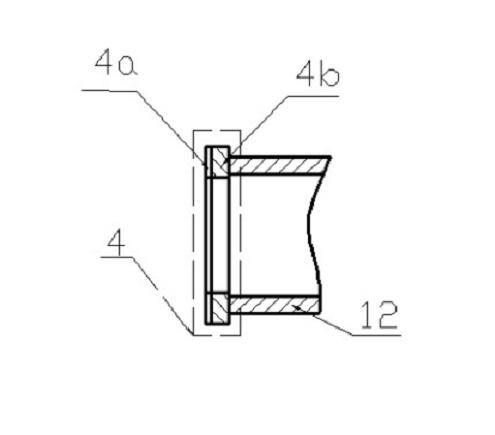

[0024] Such as figure 1 As shown, the device for guiding the axial mode wave in the axial mode of the annular laser excitation pipe has an optical bench 10 for installing and fixing various components, and the horizontal platform of the optical bench 10 is arranged in turn from left to right. The various components of the device 1, the focusing beam reduction optical path system 2, the ring light optical path system 3 and the clamping device 5 can be adjusted and fixed by the mounting bracket 11, and the clamping device is installed at a distance of 1 to 10 cm from the end surface of the pipe position. The pipe 13 to be inspected is placed near the focus point on the right side of the device of the ring light optical system 3 and is center aligned, and the position can be adjusted according to the radius of the pipe to be inspected. The focusing beam reduction optical path system 2 and the ring light optical path system 3 are installed a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com