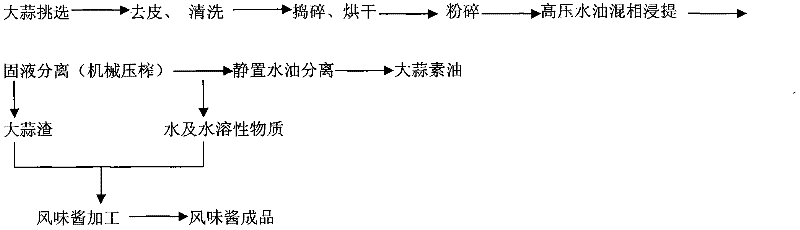

Production method for extracting allicin oil from garlic

A production method and technology of allicin, applied in the directions of edible oil/fat, food science, application, etc., can solve the problems of large environmental impact, complex process, large equipment investment, etc., and achieve no organic solvent residue, short extraction time, and process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

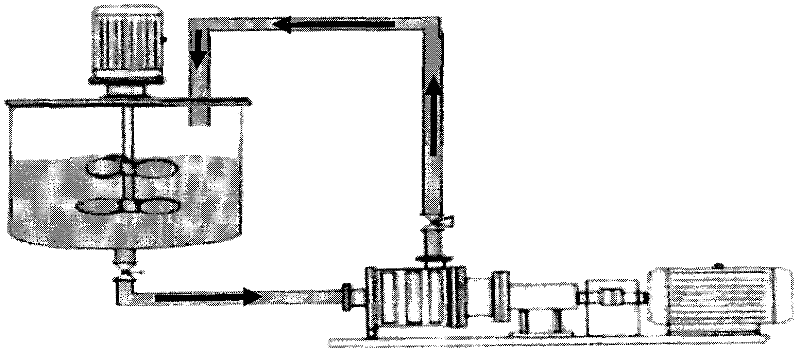

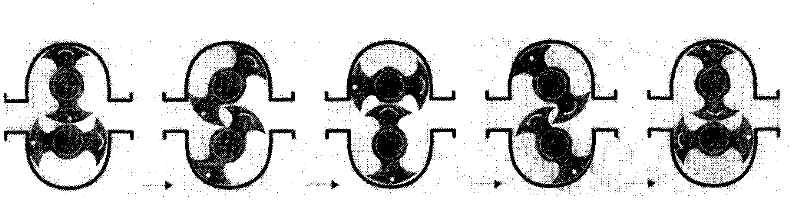

[0012] Embodiment 1: select fresh garlic without pests and mildew in Tantou Town, Longhui County, Hunan Province, remove the garlic skin, rinse the garlic with water, and remove impurities such as silt; mash the dried garlic after cleaning, and use electric hot air Tunnel dryer, baked at 60°C for 12 hours; mechanically pulverized to 80 mesh; put the pulverized material into the leaching tank with stirring rotor (36r / min), and the leaching solution is water in proportion by weight: Edible refined rapeseed oil is added in a ratio of 1:5, and the ratio of garlic and extract is 1:2 by weight. Under the working conditions of high-pressure rotor pump, a higher vacuum degree (suction-0.02-0.08Mpa) and The discharge pressure (0.1 ~ 0.6Mpa,) is extracted under the action of the extraction pressure difference for 8 hours; the extracted material is squeezed with a press to basically separate the material and liquid; the residue is applied to the subsequent processing of flavor sauce; the ...

Embodiment 2

[0013] Embodiment 2: the steps are the same as in 1, the difference in data: drying at a temperature of 80° C.; mechanically pulverizing to 80 mesh; extracting liquid prepared according to weight ratio water: edible refined rapeseed oil is a ratio of 1: 3; The liquid ratio is 1:4 by weight, and the allicin oil product is obtained by leaching for 6 hours.

Embodiment 3

[0014] Embodiment 3: the steps are the same as in 1, but the data are different: the extraction solution is prepared according to the ratio of water: edible refined rapeseed oil is 1: 4, and the ratio of material to liquid is 1: 3. After leaching for 10 hours, the finished product of allicin oil is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Proportion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com