Fluidized bed reactor for preparing methanol by synthesis gas and method

A fluidized bed reactor and fluidized bed technology, applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problems of not too high production intensity, severe wear of catalysts and heat exchange tubes, etc. , to achieve the effect of ensuring long-term stable operation, reducing gas compression costs and increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

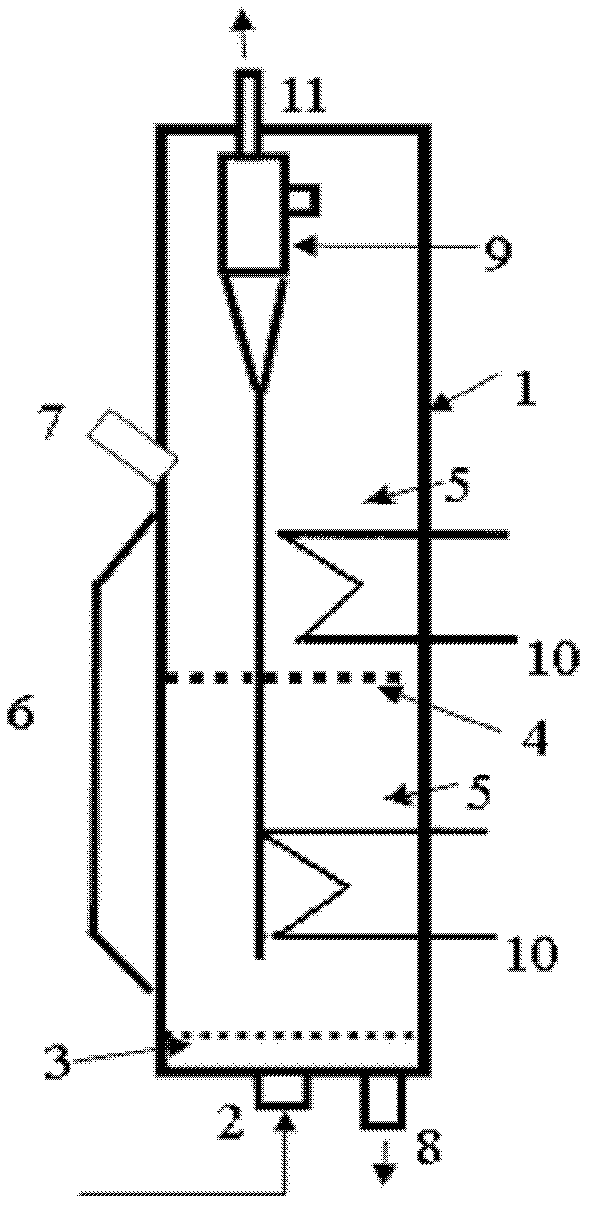

[0038] use as figure 2 The specific structure of the two-stage fluidized bed reactor shown is: the installation distance between the gas distributor 3 (porous plate type) and the first horizontal gas distribution plate 4 above it is 8 times the diameter of the fluidized bed 1; The pipe is externally placed, and the installation position is: the overflow pipe 6 connecting the first-stage catalyst dense-phase area 5 and the second-stage catalyst dense-phase area 5a, and the distance between the upper end installation position and the first horizontal gas distribution plate 4 is the fluidized bed 0.20 times of the diameter, and the distance between the installation position of the lower end and the gas distributor 3 at the lower part of the fluidized bed is 0.05 times of the diameter of the fluidized bed.

[0039] Cu / Zn / Al 2 o 3 Catalyst (copper content is 20wt%, zinc content is 30wt%, the rest is Al 2 o 3 ; Mohs hardness is 7, the average particle size is 50 microns, and th...

Embodiment 2

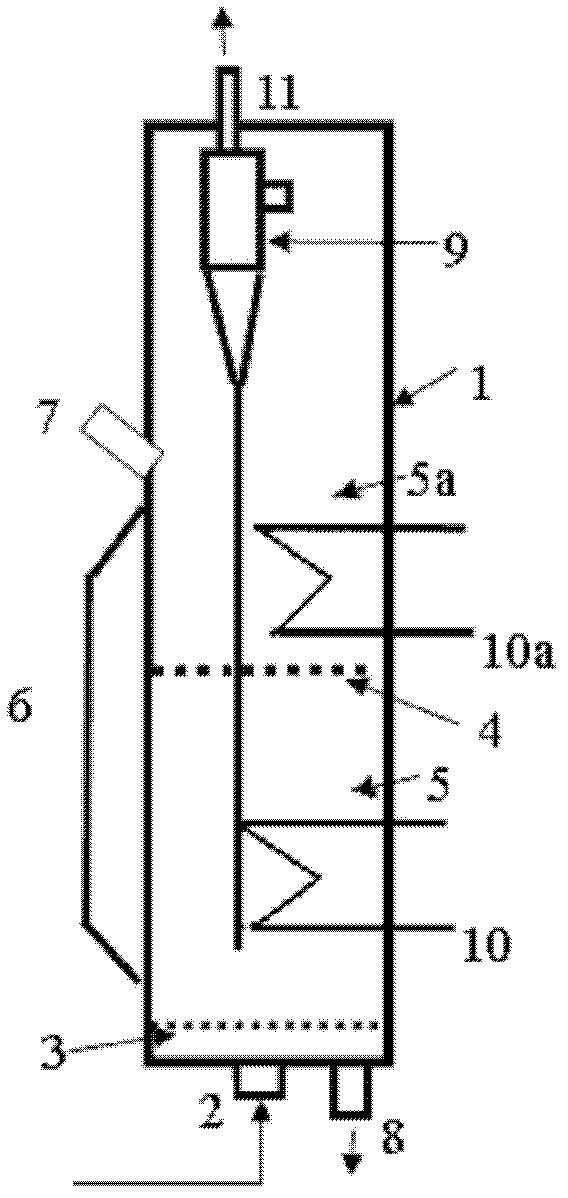

[0041] use as image 3 The specific structure of the three-stage fluidized bed reactor shown is: the installation distance between the gas distributor 3 (porous plate type) and the first horizontal gas distribution plate 4 above it is 10 times the diameter of the fluidized bed 1; The pipe adopts the combination of external and internal. The installation position of the external overflow pipe is: the overflow pipe 6 connecting the catalyst dense phase area 5 of the first stage and the catalyst dense phase area 5a of the second stage. The distance of 4a is 0.50 times the diameter of the fluidized bed 1, and the distance between the lower end installation position and the gas distributor 3 at the lower part of the fluidized bed is 0.5 times the diameter of the fluidized bed; the installation position of the built-in overflow pipe is: to connect the first stage catalyst The overflow pipe 6a of the dense phase zone 5 and the third stage catalyst dense phase zone 5b, the distance fr...

Embodiment 3

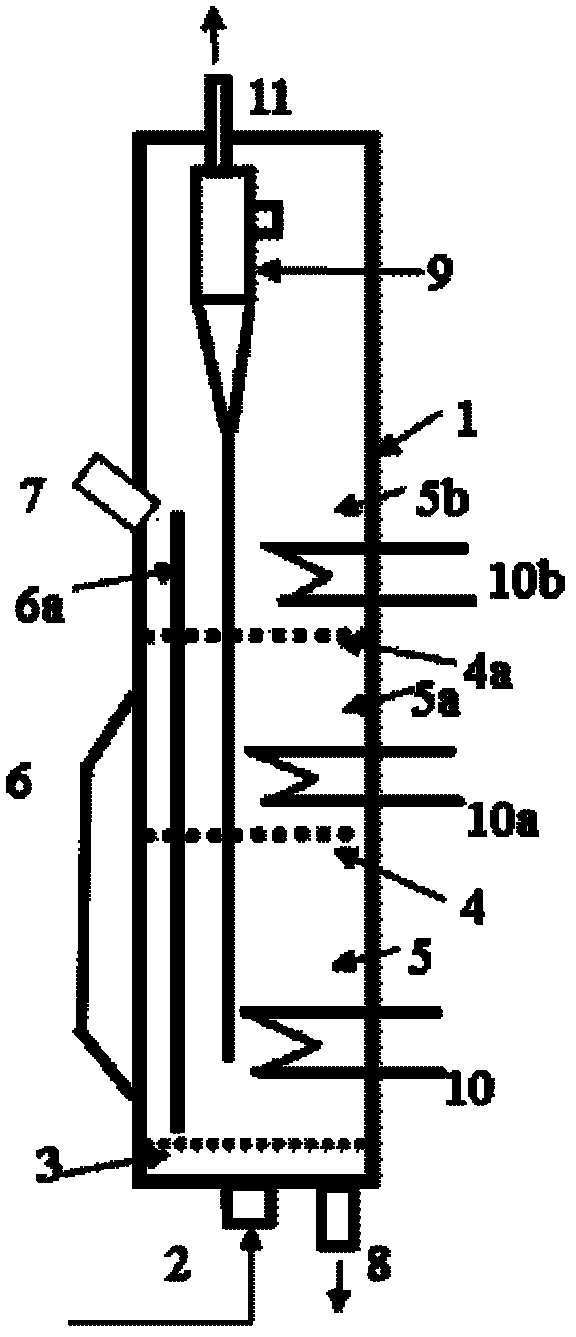

[0044] use as Figure 4The shown four-stage fluidized bed reactor has a specific structure as follows: the installation distance between the gas distributor 3 (porous plate type) and the first horizontal gas distribution plate 4 above it is 9 times the diameter of the fluidized bed 1; The pipe is externally placed, and the installation position is: the overflow pipe 6 connecting the first-stage catalyst dense-phase area 5 and the second-stage catalyst dense-phase area 5a, and the distance between the upper end of the installation position and the first transverse gas distribution plate 4 is 2 0.4 times the diameter of the bed, and the distance between the lower end installation position and the gas distributor 3 at the lower part of the fluidized bed is 0.1 times the diameter of the fluidized bed; The overflow pipe 6a, the distance between its upper end installation position and the second transverse gas distribution plate 4a is 0.4 times of the diameter of the fluidized bed, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com