Preparation method of titanium complex with high catalytic activity

A high catalytic activity, titanium complex technology, applied in the preparation of organic compounds, the preparation of hydroxyl compounds, titanium organic compounds, etc., can solve the problems of product thermal stability and product appearance defects, high catalyst production cost, and achieve difficult crystallization. , the effect of low cost and long service life of catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

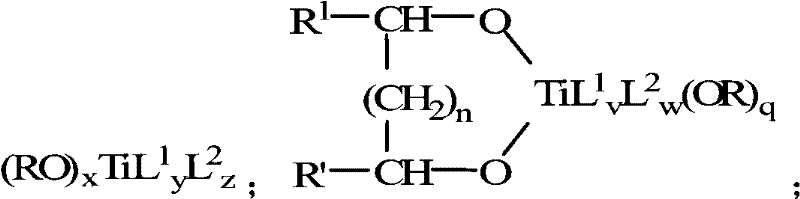

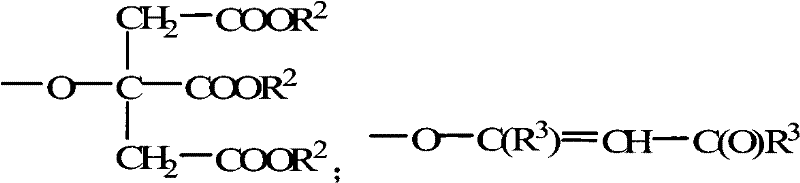

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the highly catalytically active titanium complex provided by the embodiments of the present invention comprises the following steps:

[0030] A. Add tetraisopropyl titanate to the reaction kettle, add triethyl citrate dropwise under stirring, finish dropping in half an hour, and continue stirring for half an hour;

[0031] B. Add ethyl acetoacetate dropwise, drop it in 2 to 2.5 hours, keep the reaction temperature at 60°C to 70°C, and continue stirring for 1 hour;

[0032] C, steam the isopropanol that generates with negative pressure, then add 1,2-propylene glycol wherein, the mol ratio of tetraisopropyl titanate, triethyl citrate, ethyl acetoacetate and 1,2-propylene glycol is 1:0.1-0.5:1.5-1.9:0.5-1, preferably the molar ratio is 1:0.1-0.3:1.7-1.8:0.5-0.8. Stir the reaction for 1 hour, steam the remaining isopropanol with negative pressure, and obtain the titanium complex semi-finished product;

[0033] D. Add dibutyltin dilaurate to the t...

Embodiment 1

[0036] In a 500ml four-necked glass round bottom flask equipped with a stirrer, thermometer, condenser, heater and balance feeder, tetraisopropyl titanate, triethyl citrate, ethyl acetoacetate and 1,2- The molar ratio of propylene glycol is 1:0.1:1.5:1, add 200g of tetraisopropyl titanate, and start to add 20g of triethyl citrate dropwise under stirring condition. Stir for half an hour to complete the reaction. Then slowly add 138g of ethyl acetoacetate dropwise, keep the temperature at about 70°C, finish dropping in 2.5 hours, continue to stir for 1 hour; pump low boilers with negative pressure, distill the by-product isopropanol under reduced pressure, keep warm and pump until the flow is cut off Add 53g of 1,2-propanediol, and stir for 1 hour to react; extract low boilers with negative pressure, and steam the isopropanol remaining in the system under reduced pressure until the insulation is pumped to cut off the flow; then add 2.1g of dilauric acid Dibutyltin, and a compou...

Embodiment 2

[0038] In a 500ml four-necked glass round bottom flask equipped with a stirrer, thermometer, condenser, heater and balance feeder, tetraisopropyl titanate, triethyl citrate, ethyl acetoacetate and 1,2- The molar ratio of propylene glycol is 1:0.2:1.7:0.8, add 142g of tetraisopropyl titanate, and start to add 28g of triethyl citrate dropwise under stirring condition. Stir for half an hour to complete the reaction. Then slowly add 110g of ethyl acetoacetate dropwise, keep the temperature at about 65°C, drop it in 2 hours, continue to stir for 1 hour; pump low boilers with negative pressure, distill the by-product isopropanol under reduced pressure, keep warm and pump until the flow is cut off Add 30g of 1,2-propanediol, stir and react for 1 hour; extract low boilers with negative pressure, steam the isopropanol remaining in the system under reduced pressure, keep warm and pump until the flow is cut off; add 1.5g of dilauric acid to it Dibutyltin, and compound solvent: 40g methy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com