Method for preparing ternary visible photocatalytic water splitting material with biologically-grading porous structure

A hierarchical porous and biological material technology, applied in oxygen preparation, chemical instruments and methods, chemical/physical processes, etc., to achieve simple process, good controllability, and improve the efficiency of photolysis of water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

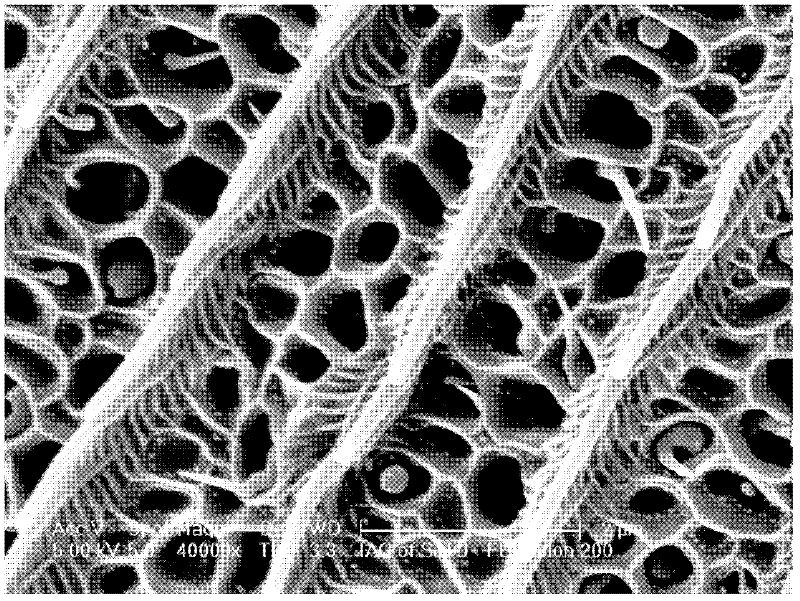

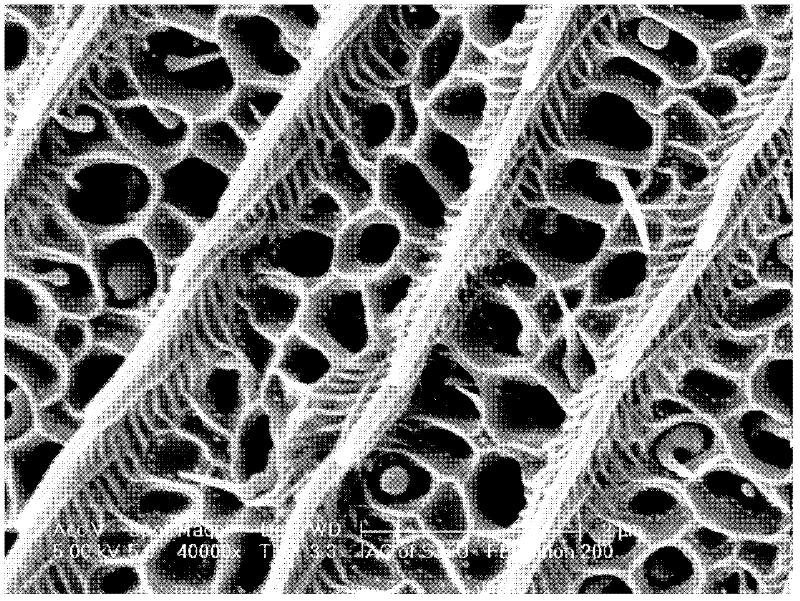

Image

Examples

Embodiment 1

[0024] In the first step, put the butterfly wing of Paris emerald phoenix into 6wt% HCl solution for 24 hours to dissolve the minerals that are not easy to be removed by sintering, and then wash it with distilled water. Then put it into 10wt% NaOH solution and treat it at 60° C. for 3 hours to dissolve most of the chitin. The butterfly wings treated in this way are taken out, rinsed with distilled water, and dried for later use.

[0025] The second step is the preparation of the precursor solution. Diethylenetriaminepentaacetic acid, bismuth oxide, and ammonium tungstate were dissolved in hot deionized water at a molar ratio of 40:1:1, and stirred at 50°C until it became a colorless and transparent precursor solution.

[0026] The third step is to immerse the treated butterfly wings in the prepared precursor solution at 50°C for 12 hours;

[0027] In the fourth step, the butterfly wings are taken out, washed several times with deionized water, dried, and then fired to remove...

Embodiment 2

[0030] In the first step, put the butterfly wing of Paris emerald phoenix into 6wt% HCl solution for 24 hours to dissolve the minerals that are not easy to be removed by sintering, and then wash it with distilled water. Then put it into 10wt% NaOH solution and treat it at 60° C. for 3 hours to dissolve most of the chitin. The butterfly wings treated in this way are taken out, rinsed with distilled water, and dried for later use.

[0031] The second step is the preparation of the precursor solution. Diethylenetriaminepentaacetic acid, bismuth oxide and ammonium molybdate were dissolved in hot deionized water in a molar ratio of 40:5:1, and stirred at 70° C. until it became a colorless and transparent precursor solution.

[0032] The third step is to immerse the treated butterfly wings in the prepared precursor solution at 70°C for 24 hours;

[0033] In the fourth step, the butterfly wings are taken out, washed several times with deionized water, dried, and then fired to remov...

Embodiment 3

[0036] In the first step, put the butterfly wing of Paris emerald phoenix into 6wt% HCl solution for 24 hours to dissolve the minerals that are not easy to be removed by sintering, and then wash it with distilled water. Then put it into 10wt% NaOH solution and treat it at 60° C. for 3 hours to dissolve most of the chitin. The butterfly wings treated in this way are taken out, rinsed with distilled water, and dried for later use.

[0037] The second step is the preparation of the precursor solution. Diethylenetriaminepentaacetic acid, bismuth oxide and ammonium iodate were dissolved in hot deionized water at a molar ratio of 40:10:1, and stirred at 90° C. until it became a colorless and transparent precursor solution.

[0038]The third step is to immerse the treated butterfly wings in the prepared precursor solution at 90°C for 48 hours;

[0039] In the fourth step, the butterfly wings are taken out, washed several times with deionized water, dried, and then roasted to remove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com