Solar cell backboard and production technique thereof

A solar cell and production process technology, applied in the field of solar cells, can solve the problems of degumming, easy embrittlement of the back sheet, high water vapor transmission rate, etc., and achieve the effects of excellent weather resistance, long service life, and high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

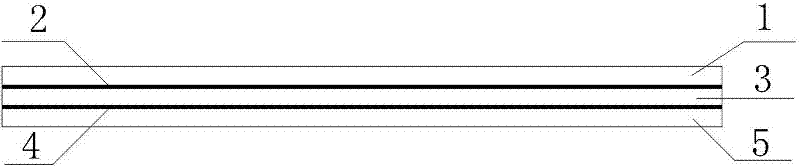

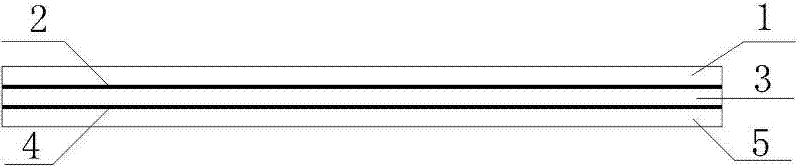

Image

Examples

Embodiment 1

[0030] A kind of production technology of solar cell back plate is characterized in that, comprises the steps:

[0031] (1) Corona is used to treat the surface of the PET film to generate low-temperature plasma, and the free radical reaction on the surface of the PET film makes the polymer cross-linked and the surface becomes rough, thereby increasing the adhesion to polar solvents;

[0032] (2) Use the KS06 glue of Coffey Chemical Co., Ltd. to prepare the adhesive, mix the main agent and curing agent of the KS06 glue evenly at a weight ratio of 50:9, and control the solid content at 35% by adding acetone;

[0033] (3) Apply the adhesive evenly on one side of the PET film, and the dry basis coating amount is 5.0g / m 2 ;

[0034] (4) Set the temperature of the oven at 60°C, dry the PET film coated with the adhesive for 2 minutes, and the hot air in the oven contacts the surface of the PET film in a swirling manner;

[0035] (5) Press the PET film and the PVDF film under hot pr...

Embodiment 2

[0040] A kind of production technology of solar cell back plate is characterized in that, comprises the steps:

[0041] (1) Corona is used to treat the surface of the PET film to generate low-temperature plasma, and the free radical reaction on the surface of the PET film makes the polymer cross-linked and the surface becomes rough, thereby increasing the adhesion to polar solvents;

[0042] (2) Use the KS06 glue of Coffey Chemical Co., Ltd. to prepare the adhesive, mix the main agent and curing agent of the KS06 glue evenly in a weight ratio of 50:9, and control the solid content at 40% by adding methyl ethyl ketone;

[0043] (3) Apply the adhesive evenly on one side of the PET film, and the dry basis coating amount is 7.0g / m 2 ;

[0044] (4) Set the temperature of the oven at 70°C, dry the PET film coated with the adhesive for 1.5 minutes, and the hot air in the oven contacts the surface of the PET film in a swirling manner;

[0045] (5) Press the PET film and the PVDF fil...

Embodiment 3

[0049] A kind of production technology of solar cell back plate is characterized in that, comprises the steps:

[0050] (1) Corona is used to treat the surface of the PET film to generate low-temperature plasma, and the free radical reaction on the surface of the PET film makes the polymer cross-linked and the surface becomes rough, thereby increasing the adhesion to polar solvents;

[0051] (2) Use the KS06 glue of Coffey Chemical Co., Ltd. to prepare the adhesive, mix the main agent and curing agent of the KS06 glue evenly in a weight ratio of 50:9, and control the solid content at 45% by adding acetone;

[0052] (3) Apply the adhesive evenly on one side of the PET film, and the dry basis coating amount is 9.0g / m 2 ;

[0053](4) Set the temperature of the oven at 80°C, dry the PET film coated with the adhesive for 1 minute, and the hot air in the oven contacts the surface of the PET film in a swirling manner;

[0054] (5) Press the PET film and the PVDF film under hot pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com