Live pig slaughtering wastewater treating method

A technology for slaughtering wastewater and a treatment method, which is applied in the field of pig slaughtering wastewater treatment, and achieves the effects of good treatment effect, easy popularization and application, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further clarified through the detailed description of specific embodiments below, but it is not intended to limit the present invention, but only for illustration.

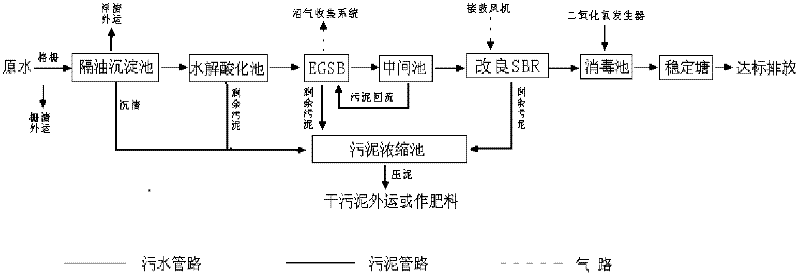

[0029] The present invention is implemented in a slaughterhouse that slaughters 100,000 live pigs a year. According to the combined process route of the present invention, a mechanical grid deslagging tank, an oil separation sedimentation tank, a hydrolytic acidification tank, an EGSB anaerobic reactor, and an intermediate sedimentation tank are built respectively. , Improved SBR ponds, disinfection ponds and stabilization ponds.

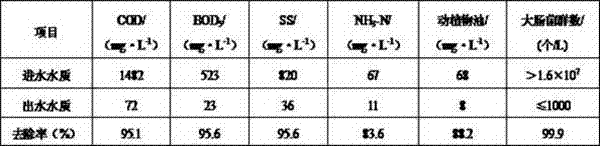

[0030] The slaughterhouse wastewater in this implementation, the daily wastewater treatment volume is 160m 3 , the wastewater quality is: COD 1200~1600mg / L, BOD 450~620 mg / L, NH 3 -N 65~72 mg / L, animal and vegetable oil 60~95 mg / L, number of coliform bacteria >1.6×10 7 a / L.

[0031]

[0032]

[0033] 1) Grille screen Grille: the grid spacing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com