Autoclaved fly ash aerated concrete building block and production method thereof

A technology of aerated concrete and production method, which is applied in the directions of climate sustainability, other household appliances, sustainable waste treatment, etc., can solve the problems of unfavorable energy saving, emission reduction and environmental protection, large consumption of quicklime and cement, etc., and achieves significant economic benefits and efficiency. Social benefits, the effect of reducing dosage and increasing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

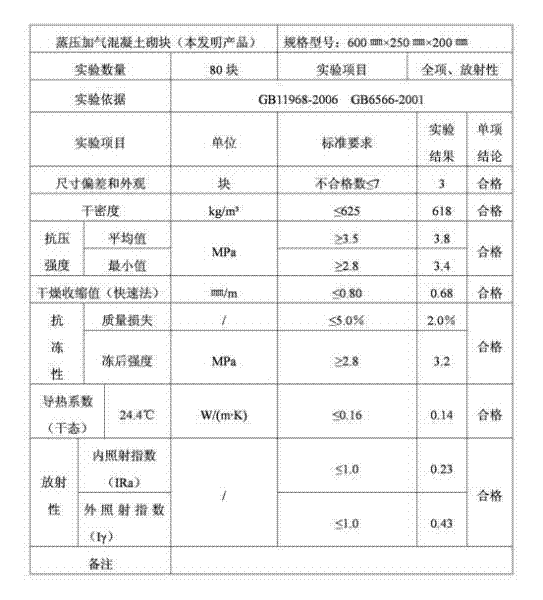

Image

Examples

Embodiment 1

[0030] The raw material composition of the autoclaved fly ash aerated concrete block of the present invention: represented by weight percentage, fly ash 75%, quicklime 18%, cement 5% and desulfurization gypsum 2%; Add foaming agent aluminum powder in addition, The amount of foaming agent aluminum powder added accounts for 0.08% of the total weight of the four raw materials of fly ash, quicklime, cement and desulfurized gypsum.

[0031] The production method of autoclaved fly ash aerated concrete block of the present invention, the detailed steps of described production method are as follows:

[0032] a, take various raw materials according to the raw material ratio ratio of the above-mentioned fly ash aerated concrete block;

[0033] b. First, pour 2025 kg of the raw material fly ash into the slurry storage tank, add water and stir and mix evenly to obtain a mixed slurry. The specific gravity of the slurry is 1.42 to 1.43. Adjust the fluidity of the mixed slurry to 28, Then a...

Embodiment 2

[0038] The raw material composition of the autoclaved fly ash aerated concrete block of the present invention: represented by weight percent, fly ash 78%, quicklime 16%, cement 4% and desulfurization gypsum 2%; Add foaming agent aluminum powder in addition, The amount of foaming agent aluminum powder added accounts for 0.07% of the total weight of the four raw materials of fly ash, quicklime, cement and desulfurized gypsum.

[0039] The production method of autoclaved fly ash aerated concrete block of the present invention, the detailed steps of described production method are as follows:

[0040] a, take various raw materials according to the raw material ratio ratio of the above-mentioned fly ash aerated concrete block;

[0041] b. First, pour 2106 kg of the raw material fly ash into the slurry storage tank, add water and stir and mix evenly to obtain a mixed slurry. The specific gravity of the slurry is 1.42-1.43. Adjust the fluidity of the mixed slurry to 30, Add 54kg of ...

Embodiment 3

[0046] The raw material composition of the autoclaved fly ash aerated concrete block of the present invention: represented by weight percentage, fly ash 73%, quicklime 17%, cement 7% and desulfurization gypsum 3%; Add foaming agent aluminum powder in addition, The amount of foaming agent aluminum powder added accounts for 0.09% of the total weight of the four raw materials of fly ash, quicklime, cement and desulfurized gypsum.

[0047] The production method of autoclaved fly ash aerated concrete block of the present invention, the detailed steps of described production method are as follows:

[0048] a, take various raw materials according to the raw material ratio ratio of the above-mentioned fly ash aerated concrete block;

[0049] b. First, pour 1971kg of the raw material fly ash into the slurry storage tank, add water and stir and mix evenly to obtain a mixed slurry. The specific gravity of the slurry is 1.42-1.43. Adjust the fluidity of the mixed slurry to 29, Then add 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com