Allowable emulsion explosive for coal mine and preparation method thereof

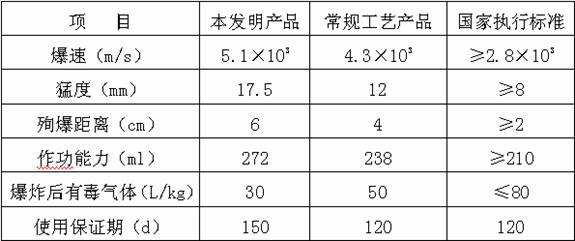

A technology of emulsified explosives and coal mines, which is applied in the direction of explosives, etc., can solve the problems of uneven size and distribution of sensitized bubbles, low explosive working ability, high viscosity of emulsified matrix, etc., and achieve remarkable economic effects, complete sensitization, and post-explosion little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The product of the present invention is composed of an oil phase part, a water phase part and a sensitized part, the oil phase part and the water phase part are prepared separately, and the prepared oil phase part and the water phase part are mixed and emulsified in a ratio of 93.8:6.2 to form an emulsified Base; the sensitized part is added to the emulsification base at a dosage of 0.25% relative to the emulsification base.

[0056] Among them, the raw material ratio of the oil phase is calculated according to the following parts by weight: special fat for emulsification 4 parts, emulsifier 1.9 parts; emulsifier is EX9139.

[0057] The raw material ratio of the water phase is calculated according to the following parts by weight: 64 parts of ammonium nitrate, 8 parts of sodium nitrate, 7 parts of potassium chloride, and 9 parts of water.

[0058] The raw material ratio of the sensitization part is calculated according to the following parts by weight: 35 parts of sodiu...

Embodiment 2

[0066] The product of the present invention is composed of an oil phase part, a water phase part and a sensitized part, the oil phase part and the water phase part are prepared separately, and the prepared oil phase part and the water phase part are mixed and emulsified in a ratio of 93.8:6.2 to form an emulsified Base; the sensitized part is added to the emulsification base at a dosage of 0.14% relative to the emulsification base.

[0067] Among them, the raw material ratio of the oil phase is calculated according to the following parts by weight: 4.7 parts of special fat for emulsification, 2.3 parts of emulsifier; the emulsifier is EX9139.

[0068] The raw material ratio of the water phase is calculated according to the following parts by weight: 66 parts of ammonium nitrate, 8.5 parts of sodium nitrate, 5 parts of potassium chloride, and 9 parts of water.

[0069] The raw material ratio of the sensitization part is calculated according to the following parts by weight: 38 ...

Embodiment 3

[0077] The product of the present invention is composed of an oil phase part, a water phase part and a sensitized part, the oil phase part and the water phase part are prepared separately, and the prepared oil phase part and the water phase part are mixed and emulsified in a ratio of 93.8:6.2 to form an emulsified Base; the sensitized part is added to the emulsification base at a dosage of 0.19% relative to the emulsification base.

[0078] Among them, the raw material ratio of the oil phase is calculated according to the following parts by weight: 5.0 parts of special fat for emulsification, 2.6 parts of emulsifier; the emulsifier is EX9139.

[0079] The raw material ratio of the water phase is calculated according to the following parts by weight: 73 parts of ammonium nitrate, 10 parts of sodium nitrate, 6 parts of potassium chloride, and 10 parts of water.

[0080] The raw material ratio of the sensitization part is calculated according to the following parts by weight: 30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com