Preparation method for high-purity dicyclohexyl amine

A dicyclohexylamine, high-purity technology, applied in the field of resource utilization and preparation of high-purity dicyclohexylamine, can solve problems such as harsh operating conditions, high-pressure equipment, and environmental pollution, and achieve high catalyst activity and long service life , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

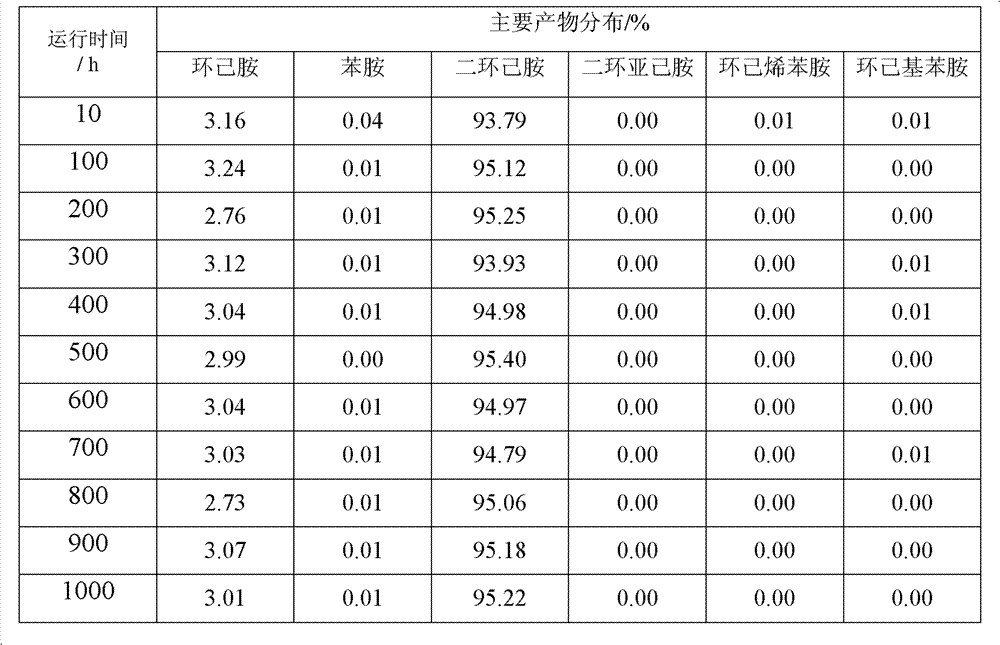

Embodiment 1

[0018] The hydrofining reactor is a tubular fixed-bed reactor with an inner diameter of 20mm. The catalyst is a nickel-based high-activity catalyst with a fixed volume of 15 mL. The catalyst is installed in the isothermal zone of the reactor, and the particle size is 20 mesh to 40 mesh. The mass ratio of each metal element of the catalyst is: Ni:Al:Mo=85:5: 5. The crude dicyclohexylamine and hydrogen are fed from the upper part of the reactor to carry out the hydrofining reaction, the products are collected and analyzed continuously from the lower end of the reactor, and the hydrogen after gas-liquid separation is recovered and reused.

[0019] The crude dicyclohexylamine injection composition (percentage by weight) is 10.15% of cyclohexylamine, 5.11% of aniline, 79.91% of dicyclohexylamine, 0.31% of dicyclohexylimine, 0.1% of cyclohexylaniline, and 1.88% of cyclohexylaniline .

[0020] Reaction conditions: 180°C, 3.5MPa, liquid volume space velocity 0.2h -1 , Hydrogen oil ...

Embodiment 2

[0024] Reaction raw materials, operation method, catalyst and consumption are as embodiment 1

[0025] Reaction conditions: 150°C, 3.5MPa, liquid volume space velocity 0.5h -1 , Hydrogen oil ratio 400.

[0026] Product distribution after hydrofining: 5.82% cyclohexylamine, 0.02% aniline, 92.61% dicyclohexylamine, 0% dicyclohexyl imine, 0.01% cyclohexylaniline, 0.02% cyclohexene aniline.

Embodiment 3

[0028] Reaction raw materials, operation method, catalyst and consumption are as embodiment 1

[0029] Reaction conditions: 140°C, 1.0MPa, liquid volume space velocity 0.4h -1 , Hydrogen oil ratio 500.

[0030] Product distribution after hydrofining: 5.93%, aniline 0.02%, dicyclohexylamine 92.4%, dicyclohexylimide 0%, cyclohexylaniline 0.01%, cyclohexene aniline 0.04%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com