Three-kettle condensation method used in solution polymerization production of synthetic rubber

A technology of synthetic rubber and coagulation method, which is applied in the field of synthetic rubber production, can solve the problems of high steam consumption and high residual solvent content, achieve the effects of strengthening heat transfer and mass transfer process, prolonging coagulation residence time, and reducing steam consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

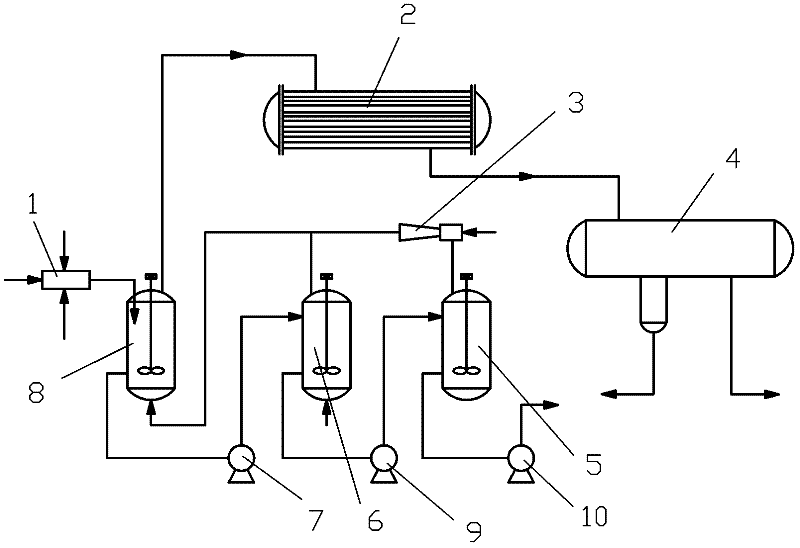

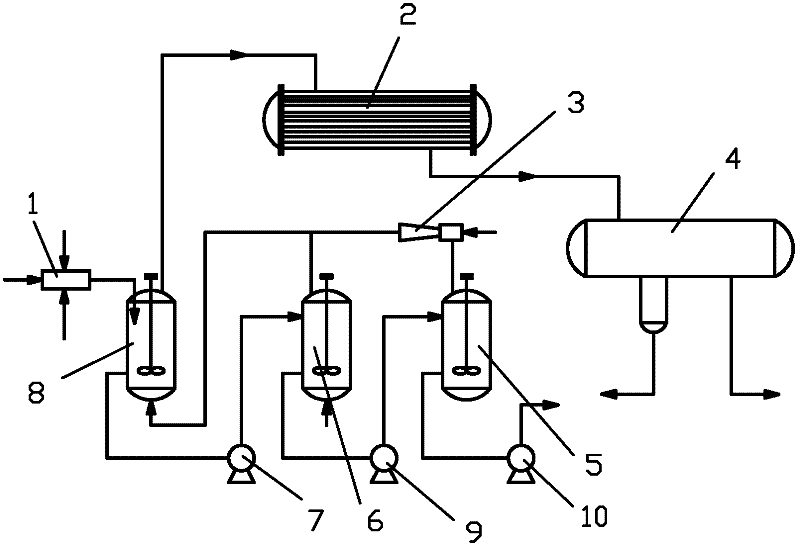

[0020] Such as figure 1 As shown, after the polymerization reaction, the glue with a glue content of 10% is sent to the coagulation process, and is fully mixed with the recycled hot water and dispersant through the ternary premixer 1 to form a heterogeneous mixture. The temperature is 85°C, the flow ratio of hot water to glue is 2, and the content of dispersant in the mixture is 20ppm.

[0021] Then it is sprayed into the coagulation first kettle 8 through the glue nozzle, the steam is injected from the bottom of the first coagulation kettle 8, and the circulating hot water enters from the middle of the first kettle to keep the liquid level stable. Under the stirring action of the glue, steam and hot water, the glue Fully heat and mass transfer with hot water and steam, the glue liquid is rapidly dispersed, and the vapor phase entrained with solvent enters the condenser 2 from the top of the kettle, and enters the oil-water stratification tank 4 after being condensed by the co...

Embodiment 2

[0027] Such as figure 1 As shown, the glue solution with a glue content of 20% after the polymerization reaction is sent to the coagulation process, and is fully mixed with the recycled hot water and dispersant through the ternary premixer 1 to form a heterogeneous mixture, wherein the hot water The temperature is 98°C, the flow ratio of hot water to glue is 4, and the content of dispersant in the mixture is 20ppm.

[0028] Then it is sprayed into the coagulation first kettle 8 through the glue nozzle, the steam is injected from the bottom of the first coagulation kettle 8, and the circulating hot water enters from the middle of the first kettle to keep the liquid level stable. Under the stirring action of the glue, steam and hot water, the glue Fully heat and mass transfer with hot water and steam, the glue liquid is rapidly dispersed, and the vapor phase entrained with solvent enters the condenser 2 from the top of the kettle, and enters the oil-water stratification tank 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com