Heat radiation material with graphite film and graphene composite structure and realization method thereof

A graphene composite and heat-dissipating material technology, applied in heat exchange materials, chemical instruments and methods, layered products, etc., can solve the problems of weak material strength, damage, and easy tearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

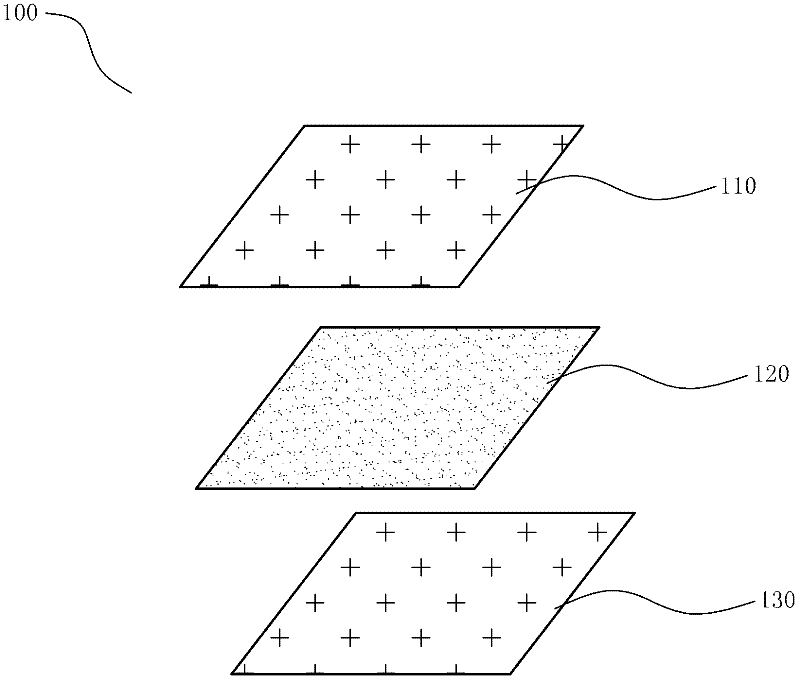

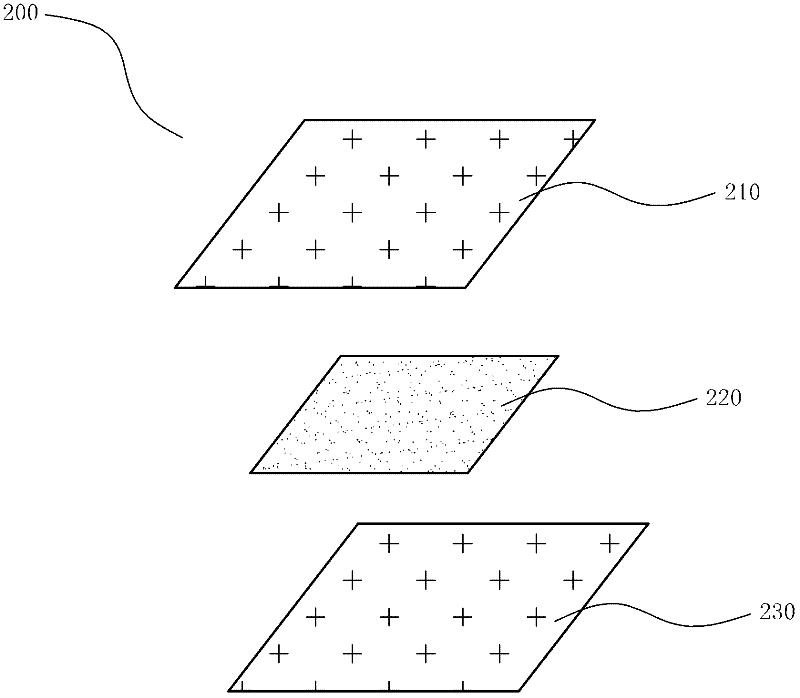

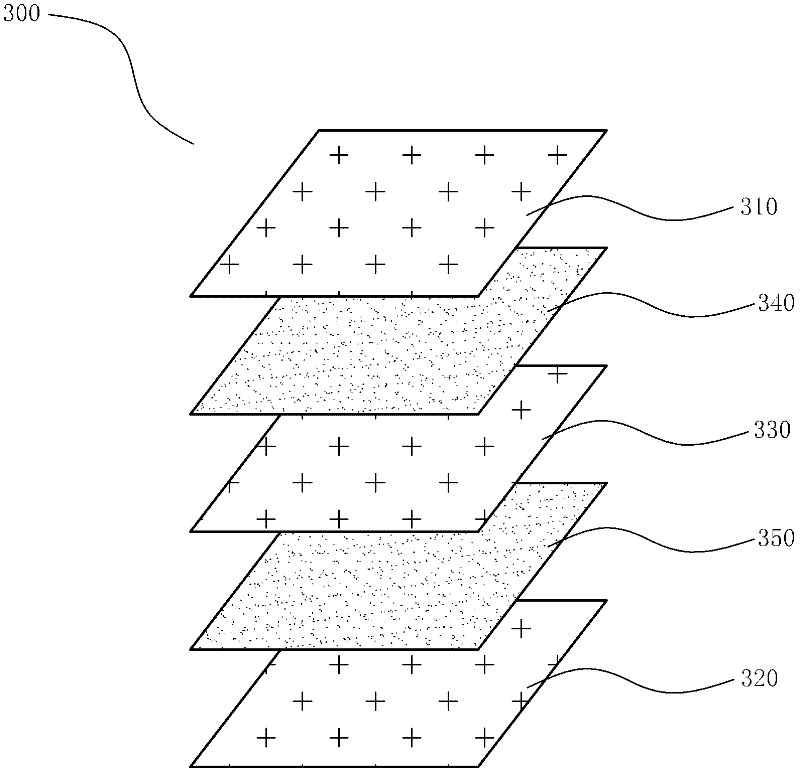

[0066] In the present invention, the composite effect between the graphite film layer and the graphene layer is used to learn from each other, so that the high heat dissipation performance of the graphite film layer can be maintained, and the original defects of the graphite film layer can be eliminated, including low surface strength. , Easy to drop debris and other shortcomings. The present invention will be further described below in conjunction with the accompanying drawings. On the other hand, the reason for such setting is that the graphite film layer with a macroscopic thickness is currently a mature technology, and the graphene layer with a macroscopic thickness is still difficult to realize at present, but a single-layer or multi-layer graphene layer, including large-scale The single-layer graphene layer has also been realized. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com