Method for transporting energy of gas-liquid two-phase flow

A gas-liquid two-phase flow and energy technology, which is applied in the field of gas-liquid two-phase flow energy transport, low energy consumption and high density energy transport, can solve the problems of difficult to achieve optimal design and complex structure, and achieve large-scale production and high-density energy transport. Large-scale application, reducing heat exchanger area, reducing the effect of irreversible losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

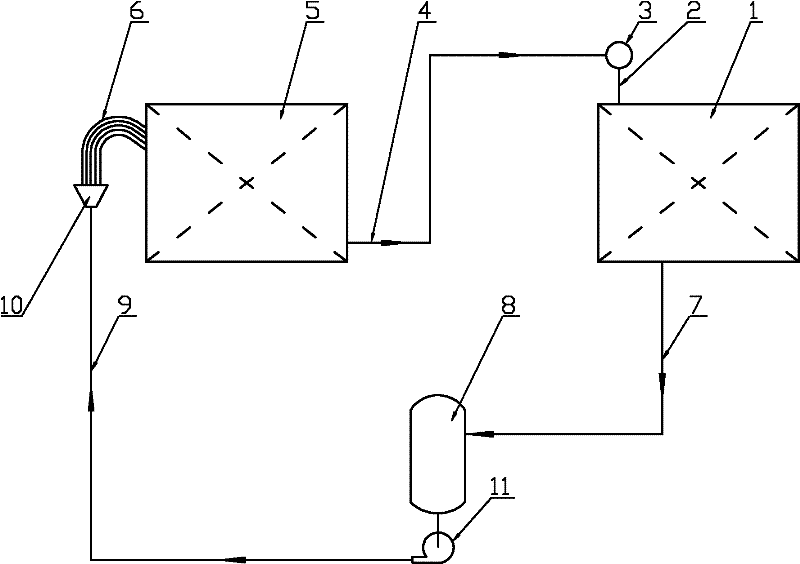

[0021] Example 1: The workflow of the first gas-liquid two-phase flow energy transport is as follows figure 1 As shown, its main components include a first evaporator 5 and a first condenser 1; it also includes a condensate liquid supply and distribution system consisting of a solution circulation pump 11, a solution transport pipe 9, a liquid separator 10 and a uniform liquid pipe 6 Subsystem: gas-liquid two-phase flow and distribution subsystem composed of gas-liquid two-phase flow main pipe 4, two-phase flow distributor 3 and two-phase flow equalizing pipe 2; liquid return main pipe 7, liquid storage tank 8 The liquid phase collection and storage subsystem constituted; the start-up and operation process of its energy transport system device is as follows: firstly, a gas-liquid two-phase flow energy transport system is figure 1 After the installation shown in the figure is completed, fill in an appropriate amount of circulating working medium after evacuation, start the solu...

Embodiment 2

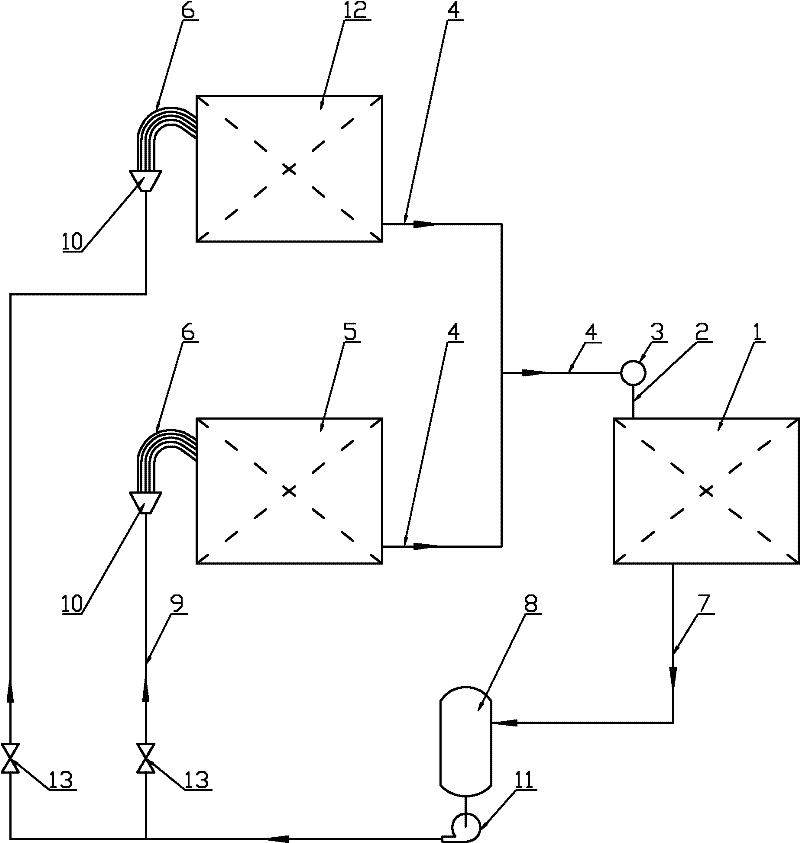

[0022] Example 2: figure 2 It is the work flow diagram of the energy transport of the second gas-liquid two-phase flow, the first condenser 1 and the liquid phase collection and storage subsystem are exactly the same as those in Embodiment 1, but the first evaporator 5 and the condensed liquid supply and The distribution subsystem and gas-liquid two-phase flow are different from the distribution subsystem. In Embodiment 1, there is only one evaporator, but in this embodiment there are more than two evaporators ( figure 2 Only 2 are drawn in ), the condensate liquid supply and distribution subsystem, the gas-liquid two-phase flow and distribution subsystem have multiple channels, and a solution regulating valve is installed on each channel of the condensate liquid supply and distribution subsystem 13. Adjust the flow rate according to the heat load of the corresponding evaporator; apply this embodiment to take heat from multiple heat sources and deliver it to a user, realizin...

Embodiment 3

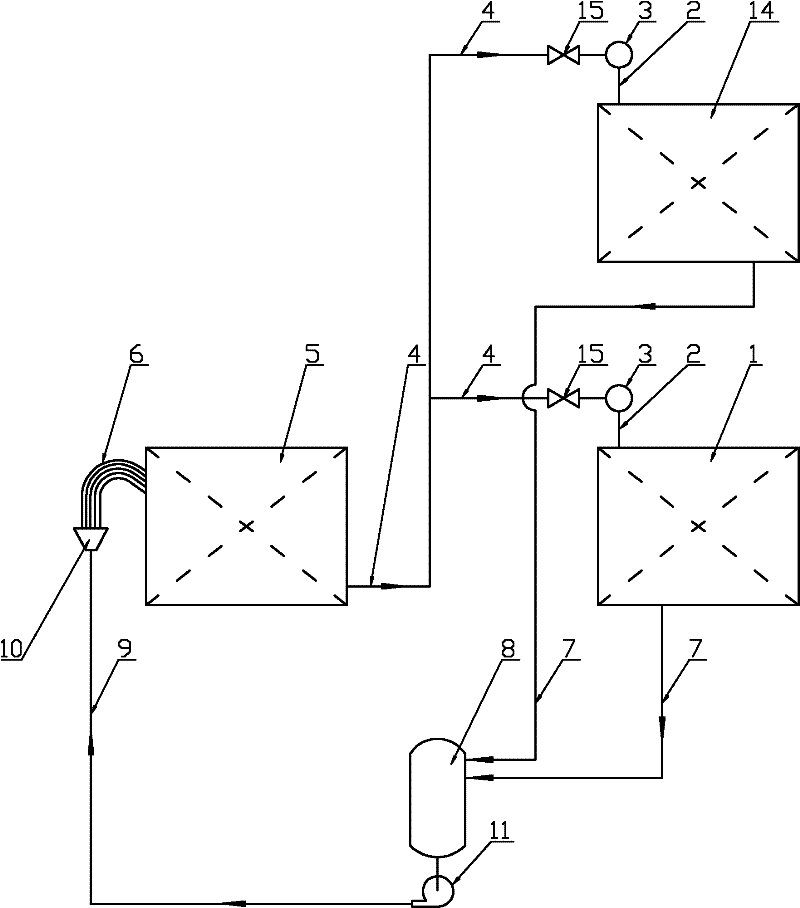

[0024] Example 3: image 3 It is the working flow diagram of the third energy transport method, the first evaporator 5 and the condensate liquid supply and distribution subsystem are basically the same as those in Embodiment 1, the condenser, the gas-liquid two-phase flow and distribution subsystem, the liquid phase Collection is different from storage; there is only one condenser in embodiment 1, and there are more than two condensers in this embodiment ( image 3 Only 2 are drawn in ), the condensate collection and storage, gas-liquid two-phase flow and distribution subsystem has multiple channels, and a two-phase flow regulating valve is installed on each channel of the gas-liquid two-phase flow and distribution subsystem 15. Adjust the flow rate according to the heat load of the corresponding condenser; apply this embodiment to take heat from one heat source and deliver it to multiple users, realizing a heat energy transportation mode of supplying multiple users.

[0025]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com