Method for determining volatile components in polyvinyl alcohol in full-evaporation headspace gas chromatography

A headspace gas chromatography and polyvinyl alcohol technology, applied in the field of instrument analysis, can solve problems such as poor repeatability, difficult work, and low stability, and achieve good reproducibility of analysis data, accuracy and reliability of analysis data, and work high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

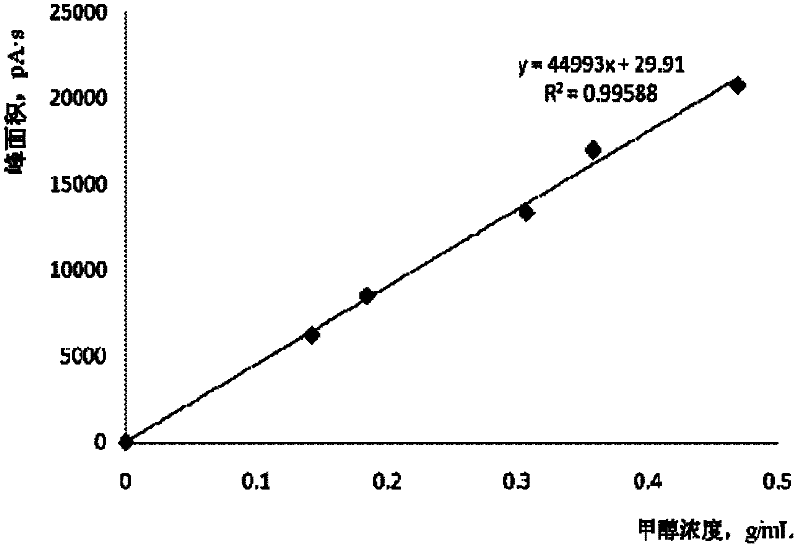

[0034] The assay method of methyl alcohol in polyvinyl alcohol (PVA) resin material of the present invention

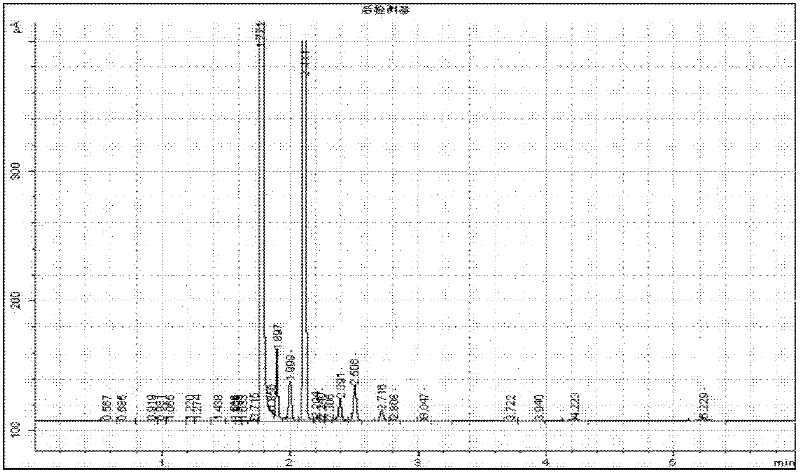

[0035] Put 0.1g to 0.5g of polyvinyl alcohol (PVA) resin material into a headspace sampler with a 20ml headspace bottle, and heat it at 120°C for 90 minutes to completely evaporate volatile components such as methanol. Analyze by gas chromatography, record the spectrum of volatile components such as methanol, and calculate the content of volatile components such as methanol by standard regression curve method.

[0036] 1. The operating conditions of the instrument are gas chromatograph: Agilent 6890 gas chromatograph (Agilent Technologies); DB-1 chromatographic column (J&W Scientific, 30m×0.45mm×2.55μm, 100% dimethyl polysiloxane); DK- Model 3001A headspace sampler (Beijing Zhongxing Institute of Analytical Instrument Technology); XS105 dual-range electronic analytical balance (METTLER TOLEDO); 20 ml headspace vials (Agilent Technologies); methanol, acetone, and methy...

Embodiment 2

[0075] Weigh 0.2235 g of the sample, accurate to 0.1 mg, place it in a 20 ml headspace vial and seal it, heat it in a headspace sampler at 120 ° C for 85 minutes, DB-1 type chromatographic column, column length 30 meters, column temperature 40 °C, FID detector, measured under the above chromatographic conditions, the peak area is 56233.6 area units. Calculated by the formula in Example 1, the methanol content in polyvinyl alcohol represented by mass percent w is 1.2498%.

Embodiment 3

[0077] Weigh 0.3936 g of the sample, accurate to 0.1 mg, place it in a 20 ml headspace vial and seal it, heat it in a headspace sampler at 115 °C for 95 minutes, DB-1 type chromatographic column, column length 30 meters, column temperature 40 °C, FID detector, measured under the above chromatographic conditions, the peak area is 76263.9 area units. Calculated by the formula in Example 1, the methanol content in polyvinyl alcohol represented by mass percent w is 1.6743%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com