Microelectronic packages and associated methods of manufacturing

A technology of microelectronic packaging and manufacturing methods, which is applied in the direction of circuits, electrical components, and electrical solid devices, can solve the problems of solder ball collapse, difficult operation, time-consuming, etc., and achieve the effect of controlling collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

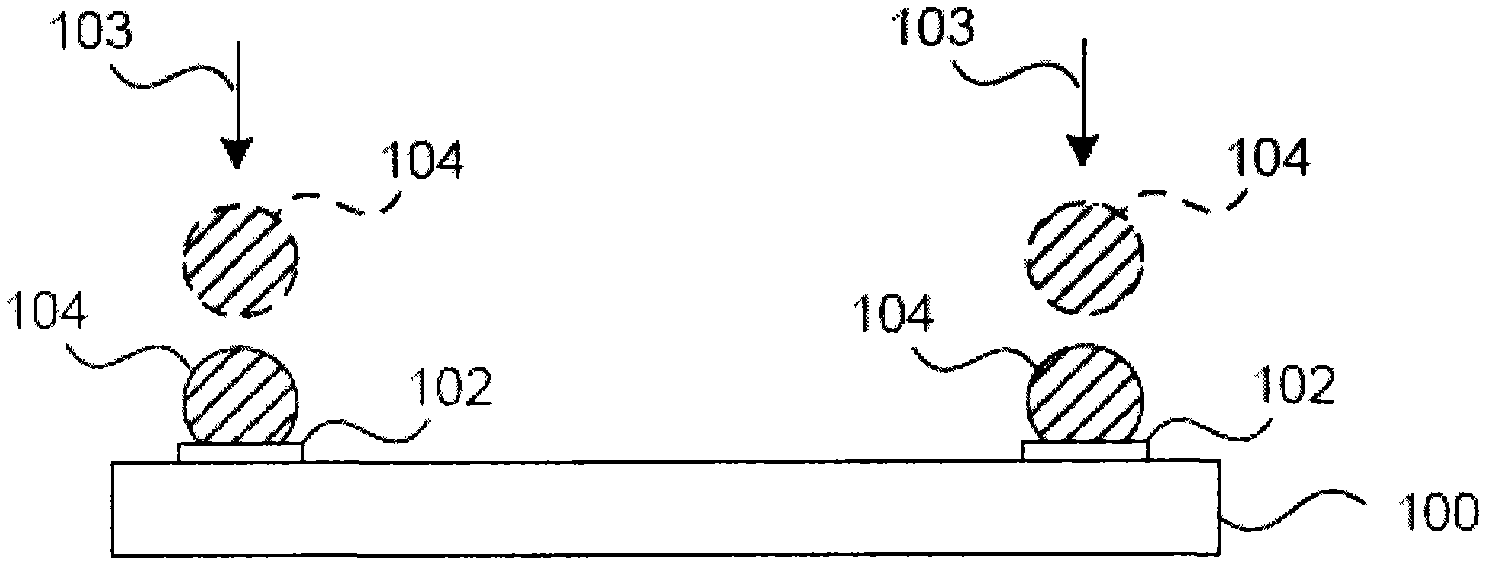

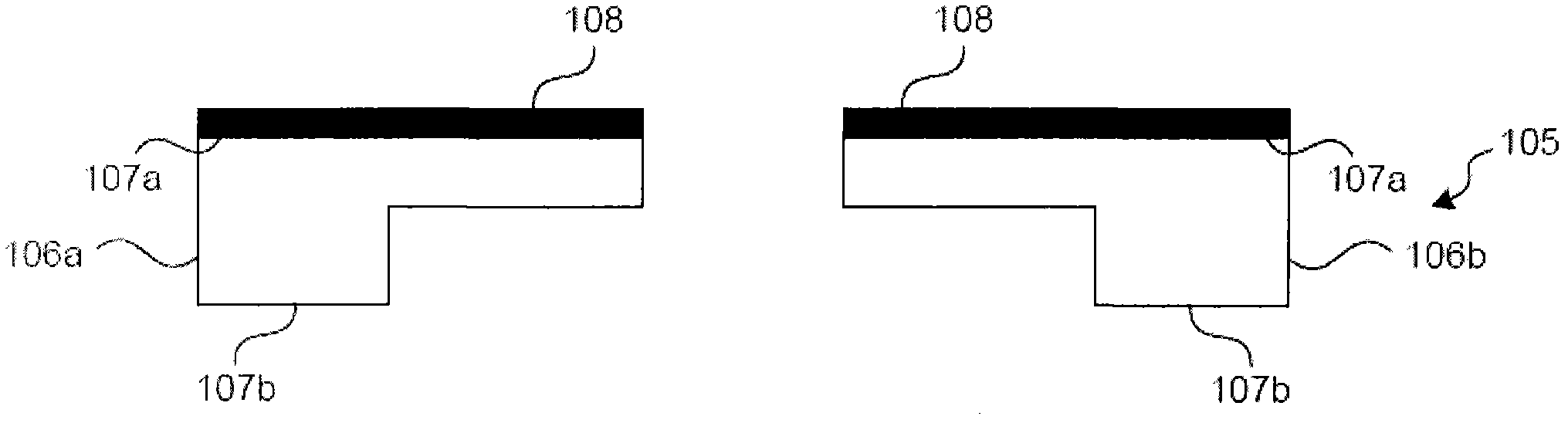

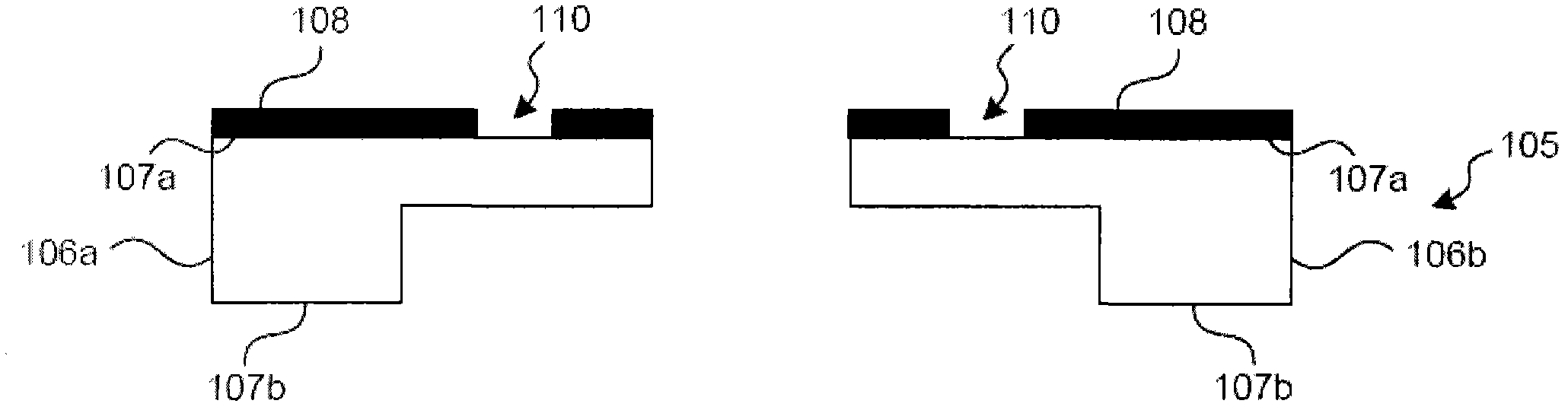

[0015] Embodiments of the present invention are described below with reference to the drawings. A package packaged with a semiconductor chip is called a microelectronic package. Usually, a microelectronic package provides protection, power supply, and cooling for the internal chip and related components while minimizing the impact on the electrical performance of the semiconductor chip, and provides electrical and external connections. and mechanical contact. A typical microelectronic package includes microelectronic circuits or components, thin film recording heads, data storage units, microfluidic devices, and other components formed on microelectronic substrates. Microelectronic substrates may include semiconductor substrates (such as wafers doped with silicon or gallium arsenide), insulating sheets (such as ceramic substrates), or conductive sheets (such as metals or metal alloys). The "semiconductor chip" referred to herein may include products used in various situations...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com