Preparing process of xanthan gum applicable to acid dairy beverages

A processing technology, a technology of xanthan gum, applied in the application, dairy products, milk preparations and other directions, can solve the problems of large fluctuation of the stability of acidic milk beverages, reduced protein precipitation, gel agglomeration, etc., and achieves improved complexation. Matching performance, improve stability, good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

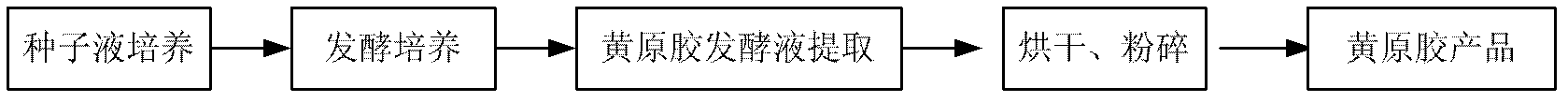

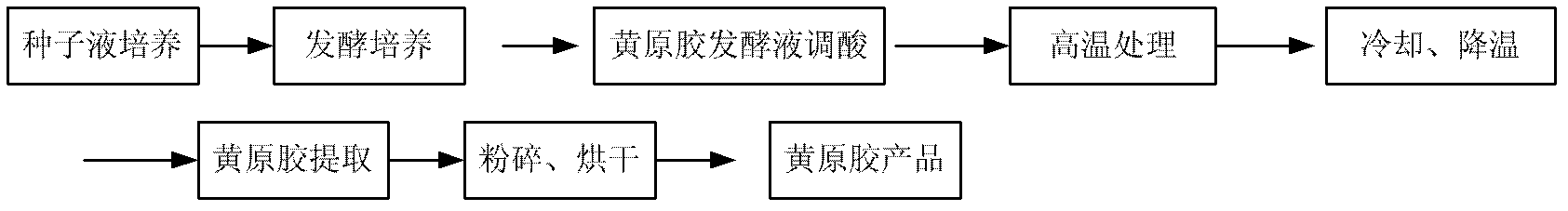

Method used

Image

Examples

Embodiment 1

[0021] According to the xanthan gum processing technology suitable for acidic milk beverages of the present invention, the seed liquid culture is carried out according to the usual xanthan gum processing technology, and then the fermentation culture is carried out to obtain the xanthan gum fermentation liquid;

[0022] Carry out acid treatment to the xanthan gum fermented liquid again: adjust the pH value of the xanthan gum fermented liquid to 3.5 with acid solution;

[0023] The acid-treated xanthan gum fermentation liquid is subjected to temperature adjustment treatment: the acid-treated xanthan gum fermentation liquid is heated to 85°C for heating and hydrolysis, maintained for 45min, and then cooled to 30°C; for the cooled xanthan gum The fermentation broth is precipitated and separated with 90° alcohol to extract xanthan gum; finally, the extracted xanthan gum is conventionally dried and pulverized to obtain a product. It can reduce the content of pyruvic acid in xanthan ...

Embodiment 2

[0025] According to the xanthan gum processing technology suitable for acidic milk beverages of the present invention, the seed liquid culture is carried out according to the usual xanthan gum processing technology, and then the fermentation culture is carried out to obtain the xanthan gum fermentation liquid;

[0026] Carry out acid treatment to the xanthan gum fermented liquid again: adjust the pH value of the xanthan gum fermented liquid to be 3.0 with acid solution;

[0027] The acid-treated xanthan gum fermentation liquid is subjected to temperature adjustment treatment: the acid-treated xanthan gum fermentation liquid is heated to 95° C. for hydrolysis, and maintained for 45 minutes, and then cooled to 30° C.; for the cooled xanthan gum The fermentation broth is precipitated and separated with 90° alcohol to extract xanthan gum; finally, the extracted xanthan gum is conventionally dried and pulverized to obtain a product. It can reduce the content of pyruvic acid in xant...

Embodiment 3

[0029] According to the xanthan gum processing technology suitable for acidic milk beverages of the present invention, the seed liquid culture is carried out according to the usual xanthan gum processing technology, and then the fermentation culture is carried out to obtain the xanthan gum fermentation liquid;

[0030] Carry out acid treatment to the xanthan gum fermented liquid again: adjust the pH value of the xanthan gum fermented liquid to be 3.0 with acid solution;

[0031] The acid-treated xanthan gum fermentation liquid is subjected to temperature adjustment treatment: the acid-treated xanthan gum fermentation liquid is heated to 92°C for heating and hydrolysis, maintained for 35min, and then cooled to 25°C; for the cooled xanthan gum The fermentation broth is precipitated and separated with 95° alcohol to extract xanthan gum; finally, the extracted xanthan gum is conventionally dried and pulverized to obtain a product. It can reduce the content of pyruvic acid in xanth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com