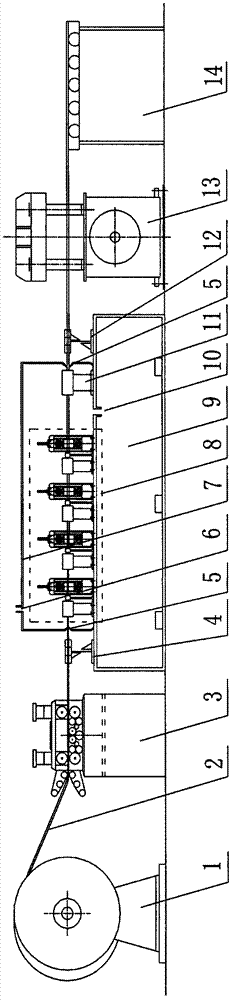

Inter-pass electromagnetic induction heating roll bending method and inter-pass electromagnetic induction heating roll bending device

A technology of electromagnetic induction heating and induction heating, which is applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of high temperature rise and rigidity drop of the roll group, low overall reliability, large temperature drop, etc., and achieve work hardening phenomenon Reduction, excellent toughness and ductility, and the effect of reducing heating power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

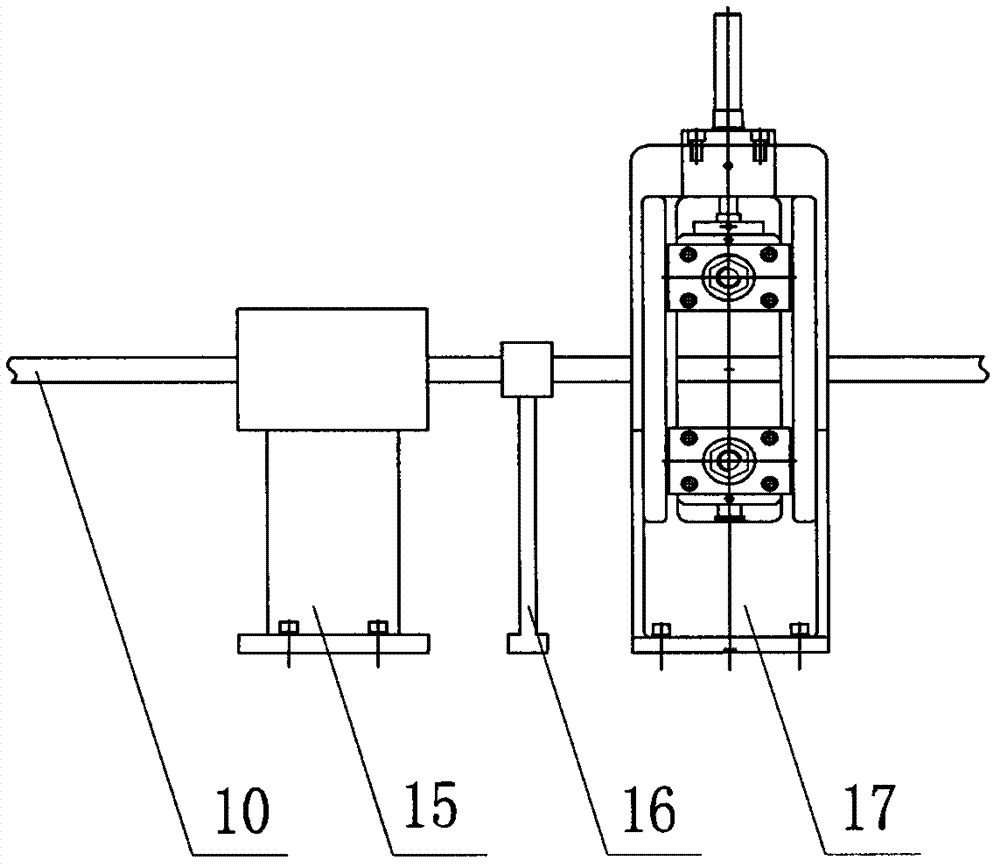

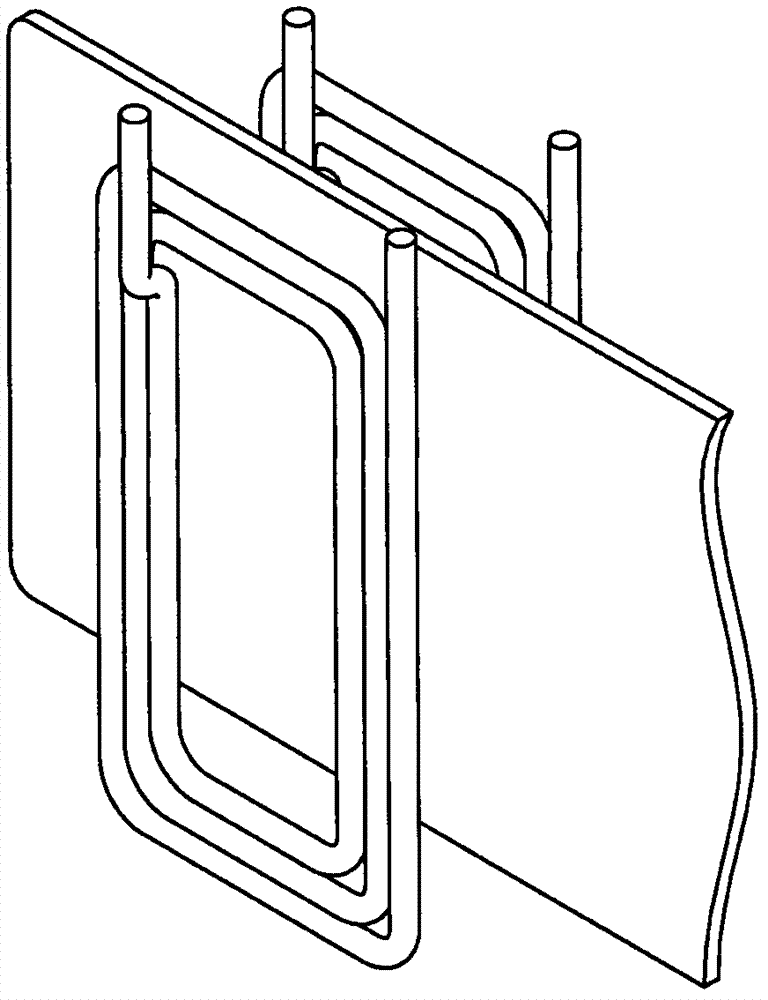

Embodiment 1

[0031] Using the electromagnetic induction heating roll forming device between passes according to the present invention, the forming section is as follows Figure 5 shown. The profiles used are OT4-1 titanium alloy profiles with a forming thickness of about 1.5 mm and a forming speed of 25 mm / s. The total number of induction heating units in the design induction heating roller group is 15. When the leveled titanium profile enters the first induction heating unit, the induction heating temperature is 650°C, and its temperature measurement device uses a radiation pyrometer as a temperature sensor; the induction heating temperature of the remaining induction heating units is controlled at 300-350°C, using Thermocouple type temperature sensor. After the titanium profile is formed by induction heating roll bending, it is cooled to room temperature by the cooling equipment and sent out to the gas shield for subsequent processes such as cutting. After roll forming, the Figure 5...

Embodiment 2

[0033] The electromagnetic induction heating roll forming device between passes is adopted, and the forming section is as follows Figure 5 shown. The profile used is 446 ferritic stainless steel, the forming thickness is about 1.5mm, and the forming speed is 25mm / s. The total number of induction heating units in the design induction heating roller group is 15. When the leveled titanium profile enters the first induction heating unit, the induction heating temperature is 950°C, and its temperature measurement device uses a radiation pyrometer as a temperature sensor; the induction heating temperature of the remaining induction heating units is controlled at 450-500°C, using Thermocouple type temperature sensor. After the profile is formed by induction heating roll bending, it is cooled to room temperature by the cooling equipment and sent out to the gas shield for subsequent processes such as cutting. After roll forming, the Figure 5 Profiles of the cross-sectional shape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com