Polyimide metal overprinting body and preparation method thereof, and dual-sided metal overprinting body

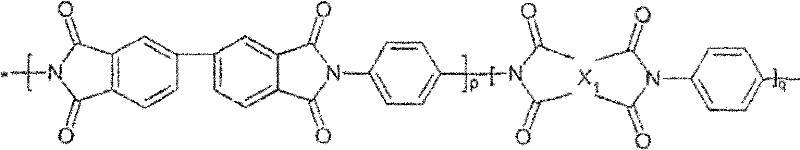

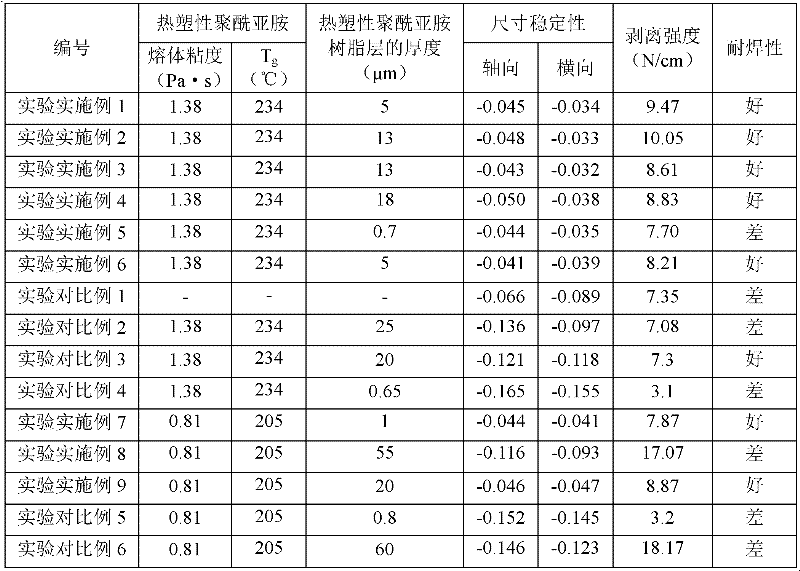

A polyimide and polyimide layer technology is applied in the fields of polyimide metal laminates and preparation methods and double-sided metal laminates, which can solve the problems of thermal expansion coefficient molecular structure limitation and the like, and achieve good dimensional stability. , the effect of high peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0088] 400mL of N,N-dimethylacetamide was placed in a glass reactor, and 22.22g of 4,4'-diaminodiphenyl ether (4,4'-ODA) was added under continuous stirring. purchased from Shandong Wanda Chemical Co., Ltd.) and stirred until completely dissolved. Then, 35.77g of 3,3',4,4'-benzophenonetetraacid dianhydride (3,3',4,4'-BTDA) (commercially purchased from Beijing Marti Technology Co., Ltd. company). The resulting mixture was stirred at 25° C. for 6 hours to obtain a polyamic acid solution (PA-1) having a solid content of 14.5% by weight and a viscosity of 53900 cP.

Synthetic example 2

[0090] 400mL of N,N-dimethylacetamide was placed in a glass reactor, and 29.90g of 1,3-bis(4-aminophenoxy)benzene (TPER) (commercially available from Qingdao Hanbing Chemical Co., Ltd.), and stir until completely dissolved. Add 30.10g of 3,3',4,4'-biphenyltetracarboxylic dianhydride (3,3',4,4'-BPDA) (commercially purchased from Shanghai Yousheng Chemical Technology Co., Ltd. ). The resulting mixture was stirred at 25° C. for 4 hours to prepare a polyamic acid solution (PA-2) having a solid content of 15% by weight and a viscosity of 9600 cP.

Synthetic example 3

[0092] 400mL of N,N-dimethylformamide was placed in a glass reactor, and 48.08g of 4,4'-diaminodiphenyl ether (4,4'-ODA) was added under continuous stirring, and Stir until completely dissolved. Then, 51.92 g of pyromellitic dianhydride (PMDA, commercially available from Fanxian Senyuan Chemical Industry Co., Ltd.) was added into the above reactor. The obtained mixture was stirred at 25° C. for 7 hours to obtain a polyamic acid solution (PA-3) having a solid content of 25% by weight and a viscosity of 25300 cP.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt viscosity | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com