Method and device for preparing aluminum-smelting carbon material, and used raw material

A preparation device, aluminum carbon technology, applied in the direction of carbon preparation/purification, solid waste removal, etc., can solve the problems of insufficient recycling, large amount of asphalt usage, long production time, etc., and achieve shortened roasting time and less ash content , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

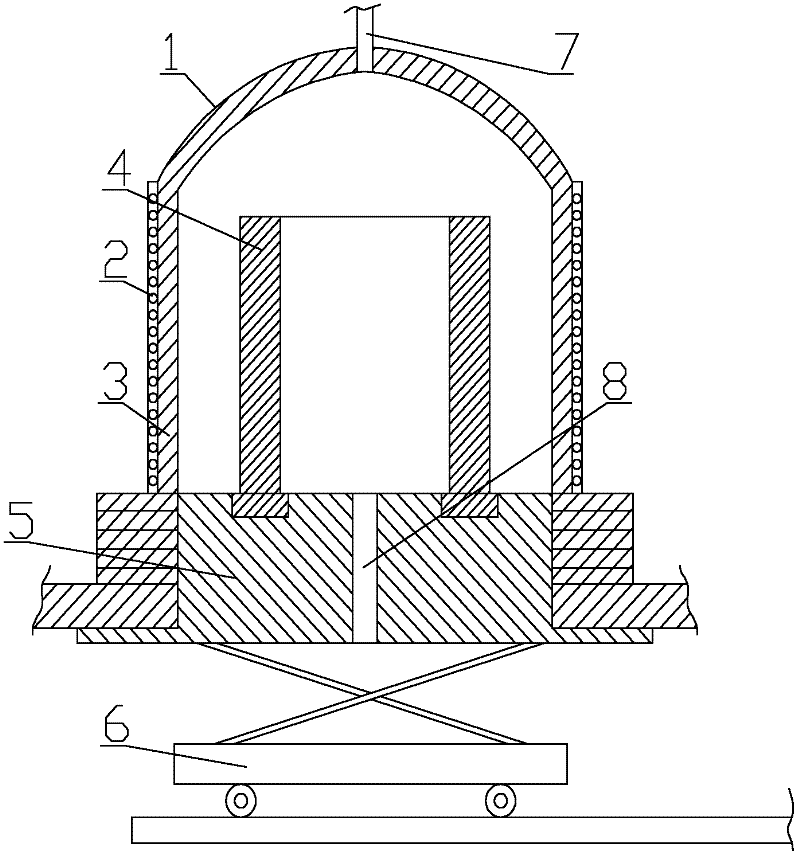

[0022] Embodiment 1 of the present invention. Aluminum smelting carbon material preparation equipment, such as figure 1 As shown, a furnace body 1 of an intermediate frequency induction roasting furnace is made, an induction coil 2 is installed on the furnace body 1, an insulation layer 3 is built in the furnace body 1, and a graphite heating ring 4 is installed in the furnace body as a heating source.

[0023] Further, the furnace body 1 is equipped with a movable base 5 on which the graphite heating ring 4 is fixed. The movable base 5 can also be arranged on the mobile frame 6, and the track of the mobile frame 6 is connected to the furnace body 1 of the intermediate frequency induction roasting furnace and the cooling system, so that the graphite heating ring 4 and the roasted material after roasting can be moved to the cooling system for further processing. After cooling, the next furnace graphite heating ring 4 and roasting materials are loaded into the furnace body 1 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com