Method for preparing zinc oxide nano sheet array

A zinc oxide nano- and nano-flaky technology, which is applied in the direction of zinc oxide/zinc hydroxide, nanotechnology, etc., can solve the problems that the commercial prospects of ZnO nanowires are not optimistic, and achieve the effect of high specific surface area and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

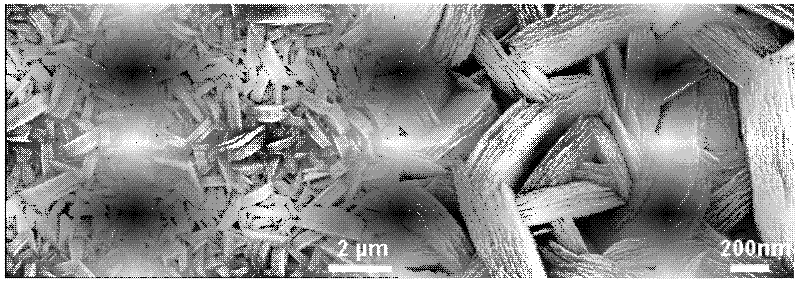

Embodiment 1

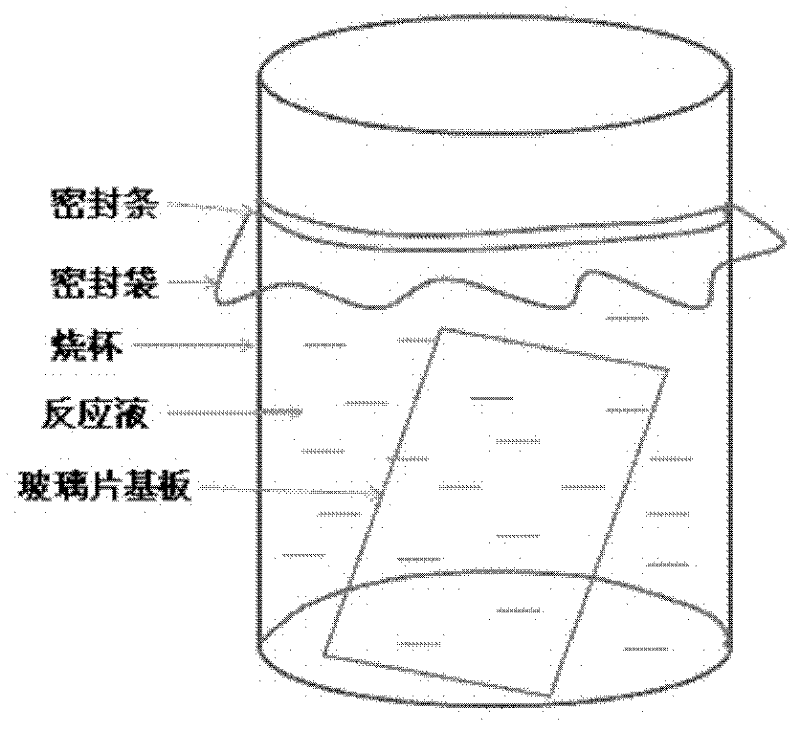

[0021] Preparation of ZnO seeds. First, under the condition of water bath at 60°C, 125mL of methanol solution of zinc acetate dihydrate with a concentration of 0.01M was prepared in the flask, and the vigorous stirring was accompanied by the whole reaction process; secondly, 65mL of methanol solution of potassium hydroxide (0.03M) was added dropwise Drop into the above solution; finally, the mixed solution was continuously stirred at 60° C. for 2 hours, and the preparation of the seed solution was completed.

[0022] The synthesized ZnO seeds were spin-coated onto coverslip (2 cm x 2 cm) substrates. Place the coverslip on the SC-1B homogenizer, add two drops of ZnO seed solution onto the surface of the coverslip at a speed of 2000 r / min, and spin-coat for 60 seconds; repeat the spin-coating three times.

[0023] Prepare the reaction solution for the growth of ZnO nanosheets. In a 50ml beaker, prepare 30ml of zinc nitrate (0.05M) and hexamethylenetetramine (0.05M) of equimola...

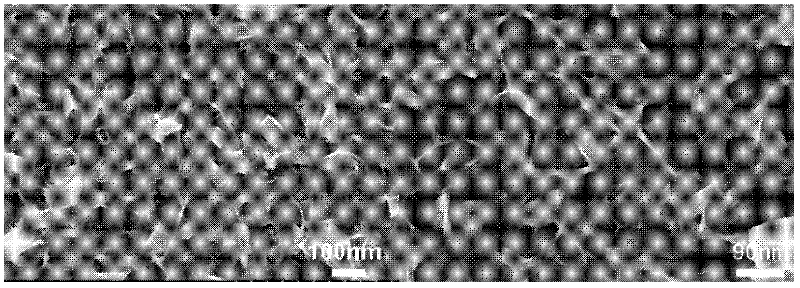

Embodiment 2

[0026] Preparation of ZnO seeds. First, under the condition of water bath at 60°C, 125mL methanol solution of zinc acetate dihydrate with a concentration of 0.013M was prepared in the flask, and the vigorous stirring was accompanied by the whole reaction process; secondly, 65mL methanol solution of potassium hydroxide (0.05M) was added dropwise Drop into the above solution; finally, the mixed solution was continuously stirred at 70° C. for 5 hours, and the preparation of the seed solution was completed.

[0027] The synthesized ZnO seeds were spin-coated onto coverslip (2 cm x 2 cm) substrates. Place the coverslip on the SC-1B homogenizer, add two drops of ZnO seed solution onto the surface of the coverslip at a speed of 2000 r / min, and spin-coat for 60 seconds; repeat the spin-coating three times.

[0028] Prepare the reaction solution for the growth of ZnO nanosheets. In a 50ml beaker, prepare 30ml of zinc nitrate (0.05M) and hexamethylenetetramine (0.05M) of equimolar con...

Embodiment 3

[0031] Preparation of ZnO seeds. First, under the condition of water bath at 60°C, 125mL methanol solution of zinc acetate dihydrate with a concentration of 0.026M was prepared in the flask, and the vigorous stirring was accompanied by the whole reaction process; secondly, 65mL methanol solution of potassium hydroxide (0.095M) was added dropwise Drop into the above solution; finally, the mixed solution was continuously stirred at 65° C. for 6 hours, and the preparation of the seed solution was completed.

[0032] The synthesized ZnO seeds were spin-coated onto coverslip (2 cm x 2 cm) substrates. Place the coverslip on the SC-1B homogenizer, add two drops of ZnO seed solution onto the surface of the coverslip at a speed of 2000 r / min, and spin-coat for 60 seconds; repeat the spin-coating three times.

[0033] Prepare the reaction solution for the growth of ZnO nanosheets. In a 50ml beaker, prepare 30ml of zinc nitrate (0.05M) and hexamethylenetetramine (0.05M) of equimolar co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com