High impact rotational-molding splash guard for automobiles

A technology of high impact resistance and fenders, applied in the chemical industry, to achieve the effect of advanced formula, good illumination and strong promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

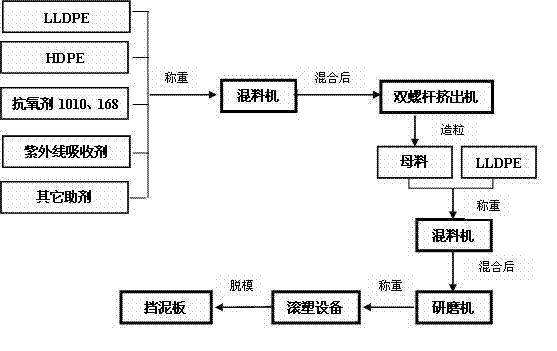

Image

Examples

Embodiment 1

[0024] The present invention makes the required material of urea tank masterbatch and consists of:

[0025] Linear Low Density Polyethylene 30 High Density Polyethylene 20

[0026] EVA 50 Calcium stearate 1 Antioxidant 1010 1

[0027] Antioxidant 168 3 UV absorber-------UV-531 2

[0028] Antistatic agent ----- hydroxyethyl alkylamine 2;

[0029] The parts by weight of the materials needed to make the urea tank consist of:

[0030] Masterbatch 8 Linear Low Density Polyethylene 92. The masterbatch and LLDPE are mixed in this ratio, which avoids all materials being re-pelletized in the twin-screw extruder, causing unnecessary degradation of the material.

[0031] The present invention weighs linear low-density polyethylene, high-density polyethylene, EVA, calcium stearate, antioxidant 1010, antioxidant 168, ultraviolet absorber and antistatic agent according to the proportioning; , put linear low-density polyethylene, high-density polyethylene, EVA, calcium stearate, antioxi...

Embodiment 2

[0033] The present invention makes the required material of urea tank masterbatch and consists of:

[0034] Linear Low Density Polyethylene 30 High Density Polyethylene 20

[0035] EVA 50 Calcium stearate 1 Antioxidant 1010 1

[0036] Antioxidant 168 3 UV absorber-------UV-531 2

[0037] Antistatic agent ----- hydroxyethyl alkylamine 2;

[0038] The parts by weight of the materials needed to make the urea tank consist of:

[0039] Masterbatch 9 Linear Low Density Polyethylene 91. The masterbatch and LLDPE are mixed in this ratio, which avoids all materials being re-pelletized in the twin-screw extruder, causing unnecessary degradation of the material.

[0040] Production method is identical with embodiment 1.

Embodiment 3

[0042] The present invention makes the required material of urea tank masterbatch and consists of:

[0043] Linear Low Density Polyethylene 30 High Density Polyethylene 20

[0044] EVA 50 Calcium stearate 1 Antioxidant 1010 1

[0045] Antioxidant 168 3 UV absorber-------UV-531 2

[0046] Antistatic agent ----- hydroxyethyl alkylamine 2;

[0047] The parts by weight of the materials needed to make the urea tank consist of:

[0048] Masterbatch 10 Linear Low Density Polyethylene 90. The masterbatch and LLDPE are mixed in this ratio, which avoids all materials being re-pelletized in the twin-screw extruder, causing unnecessary degradation of the material.

[0049] Production method is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com