Clean-type burning coke automatic monitoring and quenching device for heat recovery coke furnace

A heat recovery and clean technology, applied in furnace safety devices, coke ovens, coke cooling, etc., can solve problems such as coke bin reburning, prevent reburning accidents, reduce carbon monoxide concentration, and prevent workers from hypoxia and suffocation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

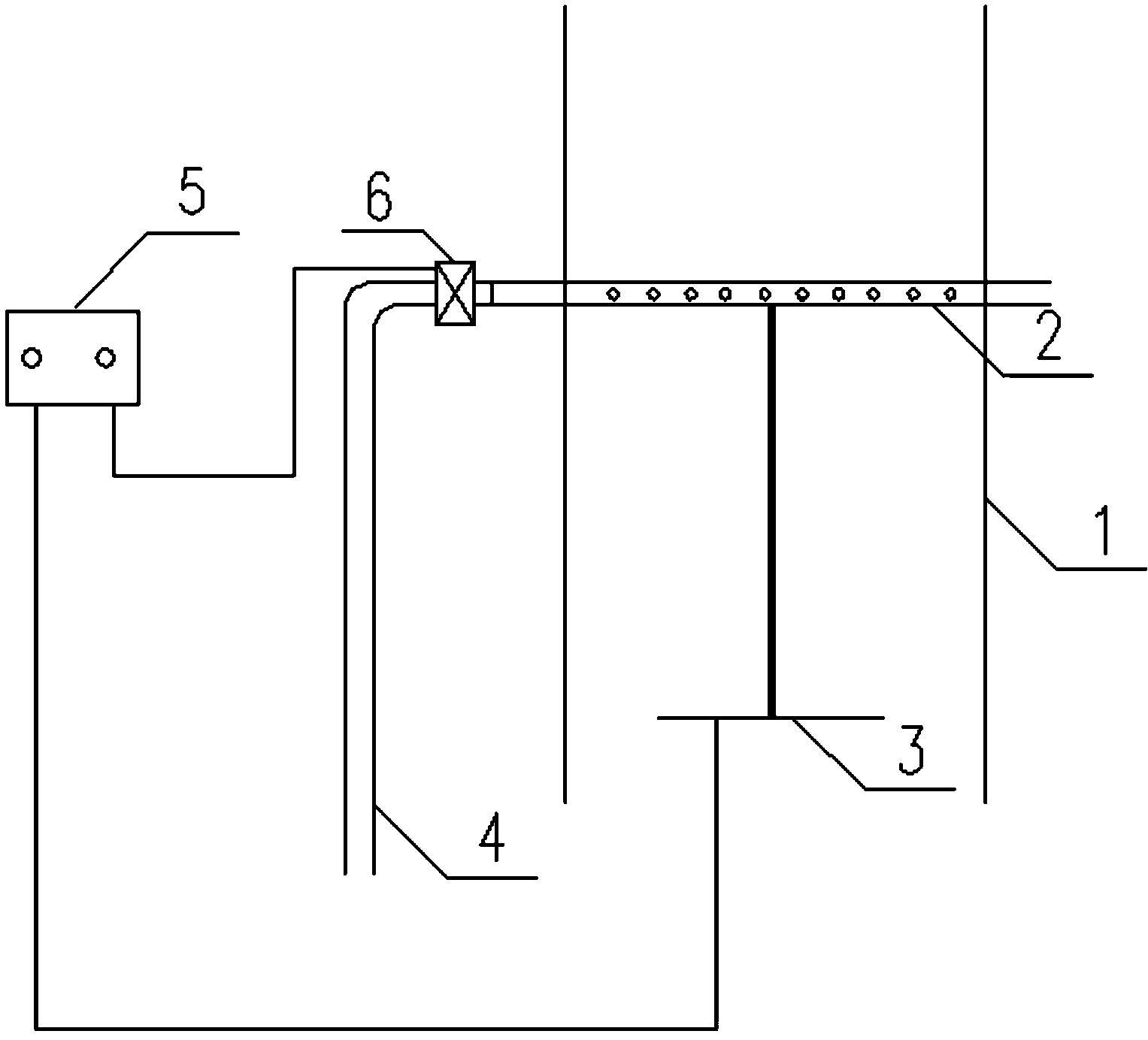

[0011] A clean heat recovery coke oven red coke automatic monitoring and extinguishing device, including a coke transportation system 1, a spray system 2, an online temperature measurement device 3, a water supply system 4, an intelligent control system 5, and an execution system 6. The spray Several coke quenching nozzles of the system 2 are located above the belt of the coke transportation system 1, the end of the pipeline of the spray system 2 is connected to the execution system 2, one end of the execution system 6 is connected to the water supply system 4 through valves and pipelines, and the other end is connected to the water supply system 4 through valves and pipelines. The circuit is connected with the intelligent control system 5, and the online temperature measuring device 3 is located above the belt of the coke transportation system 1, and is connected with the intelligent control system 5 through the circuit.

[0012] The working process of the device is as follows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com