Method for growing patterned graphene film on surface of hydroxyapatite

A technology of hydroxyapatite and surface growth, applied in gaseous chemical plating, medical science, metal material coating technology, etc., can solve problems such as low strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] (1) Deposit a layer of copper with a thickness of 1 micron on the surface of hydroxyapatite ceramics by conventional electron beam evaporation.

[0013] (2) Pass acetylene, hydrogen and argon into the reaction chamber of the Aixtron Black Magic deposition system, react at 900 degrees Celsius for 5 minutes, and grow graphene on the surface of hydroxyapatite deposited with copper by chemical vapor deposition.

[0014] (3) After cooling, the designed graphene layer is covered on the surface of the material by corroding the copper layer. This step is done by etching with 30% ferric chloride for 10 minutes.

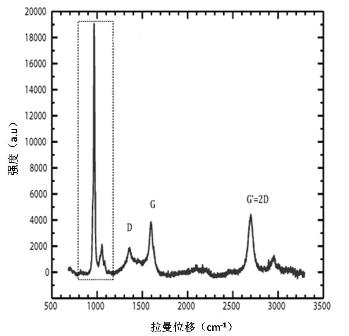

[0015] (4) Use Raman spectroscopy to demonstrate material properties.

Embodiment 2

[0017] The method steps and parameters of this embodiment are basically the same as those of Embodiment 1, except that a layer of nickel with a thickness of 1 micron is deposited on the surface of the hydroxyapatite ceramic in step (1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com