A double-gradient artificial lamina and its preparation method

A dual-gradient, artificial technology, applied in the field of biomedical materials, can solve the problems of insufficient compatibility and anti-adhesion, poor new bone formation ability, and no osteoinductivity, etc., to achieve good osteoconduction and osteoinductivity, Good soft tissue compatibility and anti-adhesion ability, excellent osteoinductive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

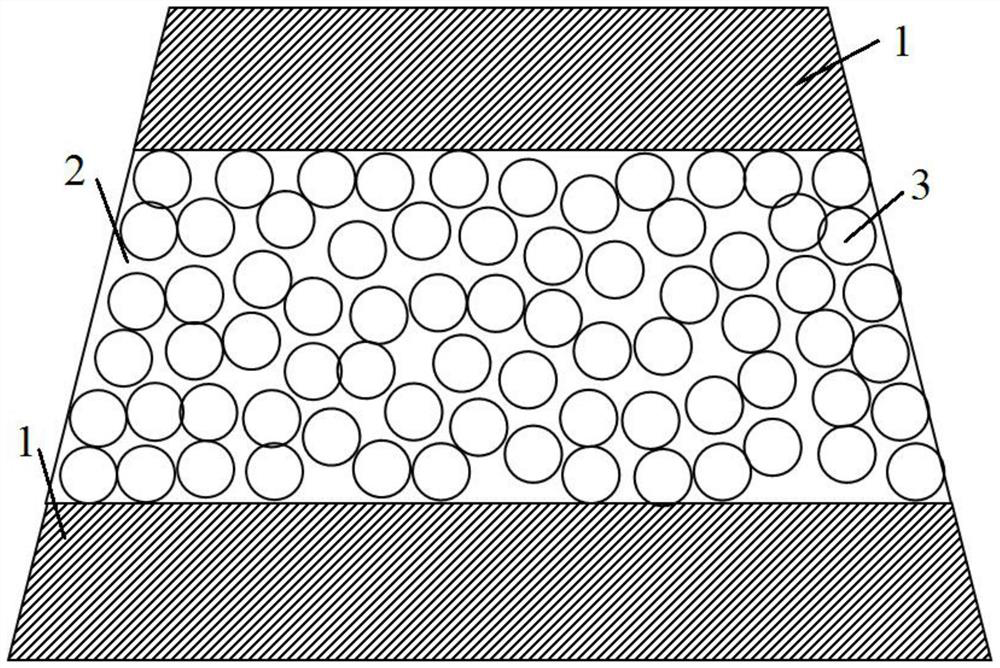

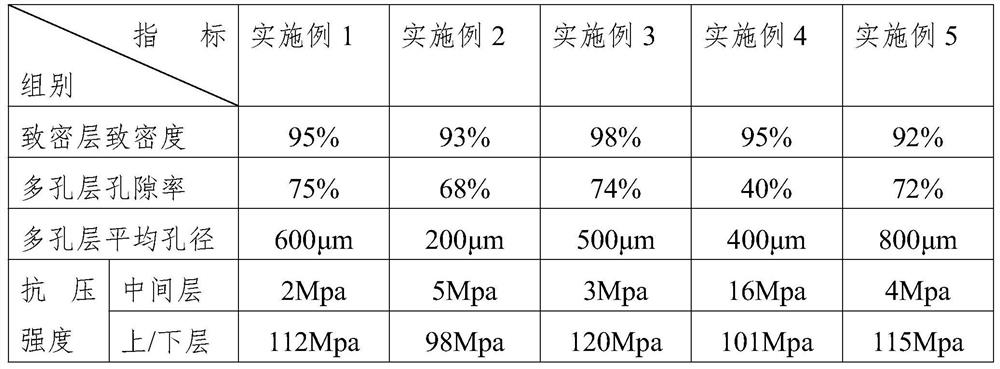

[0028] Embodiment 1, a kind of double-gradient artificial lamina

[0029] The artificial lamina described in Example 1 is a matrix with a trapezoidal cross-section and an axial length. The matrix is composed of an upper layer, a middle layer and a lower layer. The upper layer and the lower layer are hydroxyapatite ceramic layers 1, and the The middle layer is a biphasic calcium phosphate ceramic layer 2, and the upper and lower layers are dense structure layers with a thickness of 1 mm. The middle layer is a porous structure layer with a porosity of 75%.

[0030] Preparation:

[0031] A) Raw material preparation:

[0032] Preparation of nano-hydroxyapatite powder or slurry: Mix 0.835mol / L calcium nitrate aqueous solution and 0.5mol / L diammonium hydrogen phosphate aqueous solution in equal volumes, the calcium-phosphorus ratio is 1.67, adjust the pH of the solution to 11.0 with ammonia water, Stir and react for 12 hours, then age at 60°C for 24 hours, wash with deionized ...

Embodiment 2

[0038] Embodiment 2, a kind of double-gradient artificial lamina

[0039]The difference between embodiment 2 and embodiment 1 is that the binding agent described in steps B) and C) is polyethylene glycol, the dispersant is citric acid, and the pore-forming agent is polymethyl methacrylate, and the step D ) the isostatic pressure is 300MPa, and the step E) is: place the above-mentioned green body in the furnace cavity of a muffle furnace sintering furnace, use a muffle furnace for sintering, and raise the temperature at a heating rate of 0.5°C / min To 150°C, keep warm for 10min; then raise the temperature to 500°C at a heating rate of 0.5°C / min, and keep warm for 10minh; then raise the temperature to 600°C at a heating rate of 0.5°C / min, keep warm for 30min to decompose the organic matter; continue to use Sintering in a muffle furnace, heating up to 1000°C at a heating rate of 10°C / min, holding time for 1h, and lowering the temperature to room temperature at a cooling rate of ...

Embodiment 3

[0040] Embodiment 3, a kind of double-gradient artificial lamina

[0041] The difference between Example 3 and Example 1 is that the binder in steps B) and C) is polyethylene glycol, the dispersant is ammonium citrate, and the pore-forming agent is polystyrene. The isostatic pressing pressure is 500MPa, and the step E) is: place the above-mentioned green body in the furnace cavity of a muffle furnace sintering furnace, use a muffle furnace for sintering, and raise the temperature to 250°C at a heating rate of 20°C / min. ℃, hold for 2 hours; then raise the temperature to 500°C at a heating rate of 3°C / min, and hold for 4 hours; then raise the temperature to 800°C at a heating rate of 20°C / min, and hold for 4 hours to decompose organic matter; continue to use muffle Furnace sintering, heating up to 1200°C at a heating rate of 20°C / min, holding time for 4 hours, and lowering the temperature to room temperature at a cooling rate of 100°C / min; cutting to obtain artificial lamina w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com