Plasma enhanced chemical vapor deposition vacuum equipment

A chemical vapor deposition, vacuum equipment technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve problems such as mutual pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

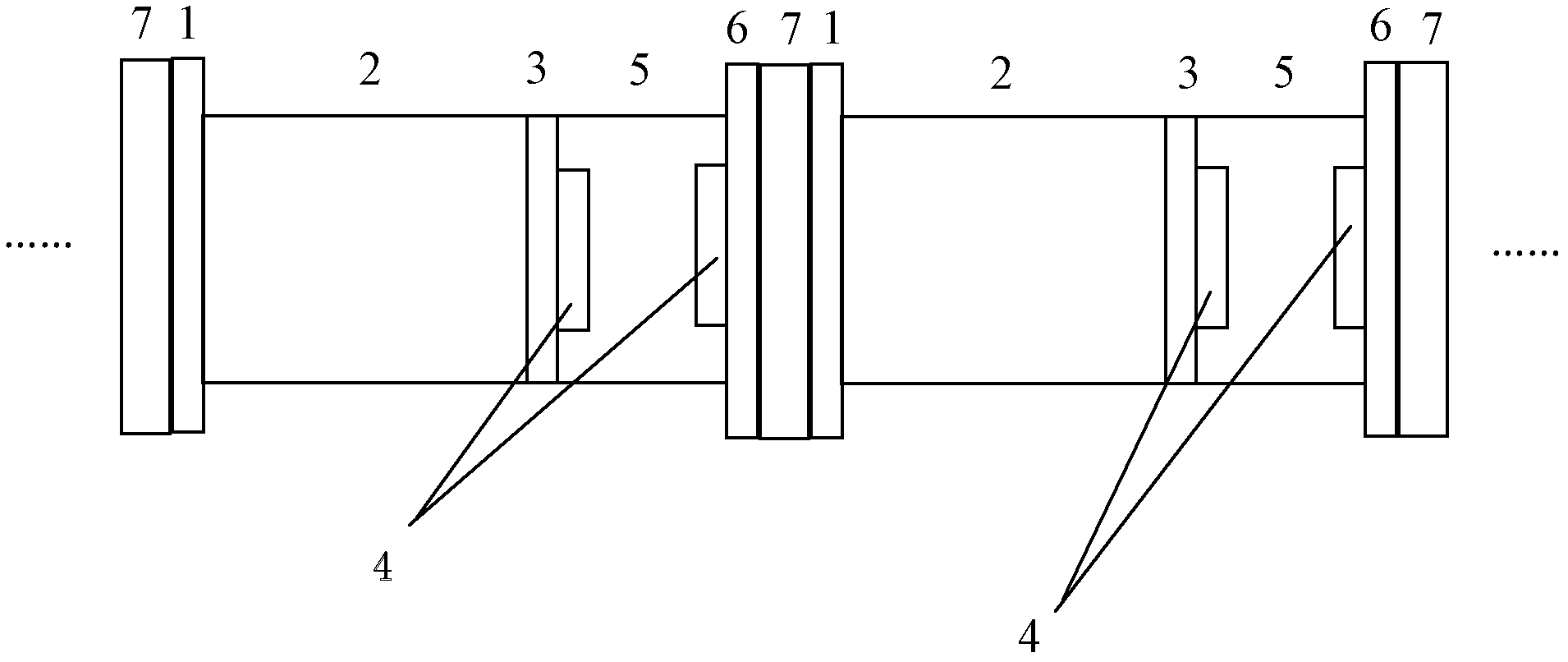

[0053] see figure 1 , the present invention is a plasma-enhanced chemical vapor deposition (PECVD) vacuum equipment design method, enumerating specific examples as follows:

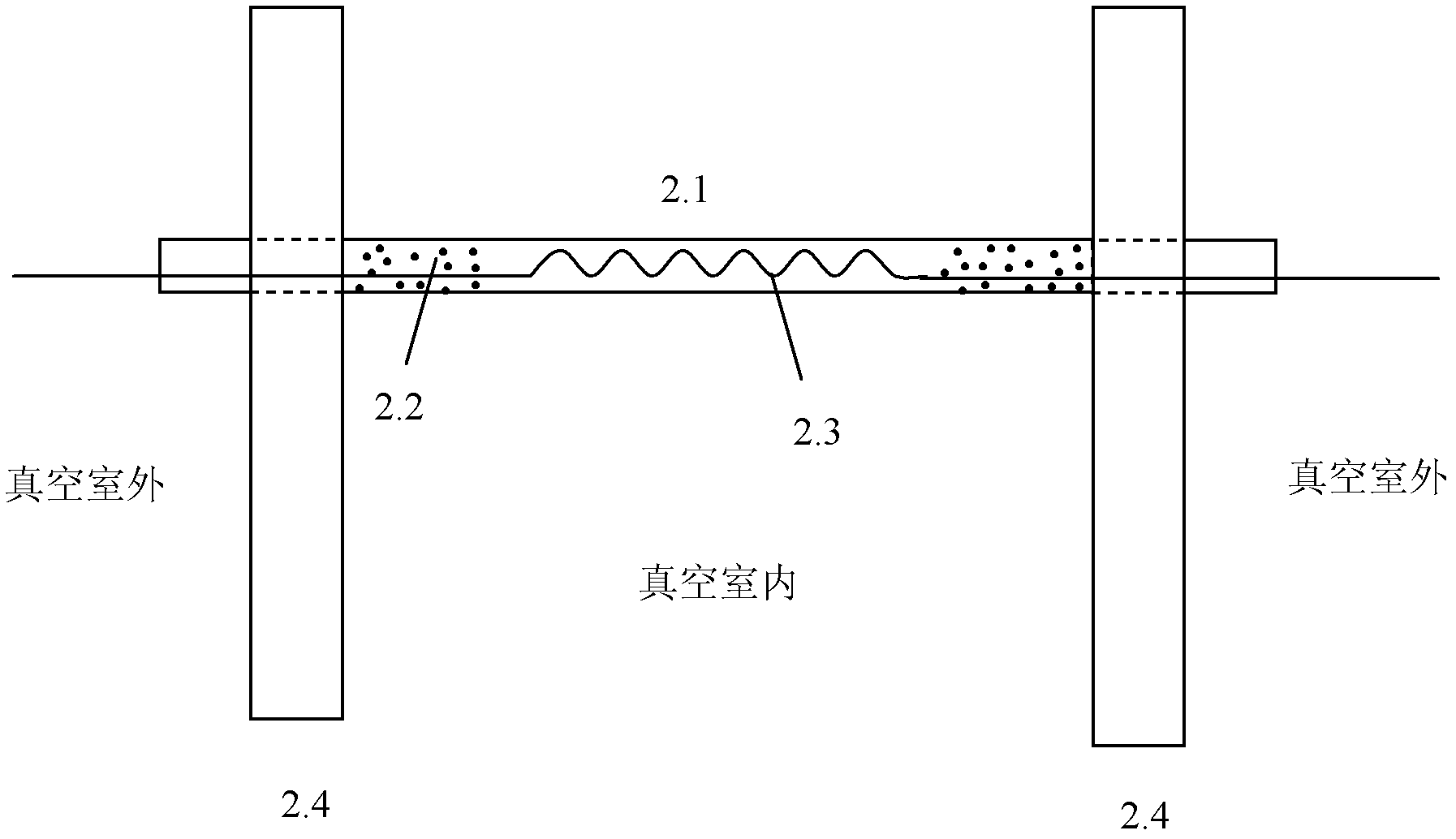

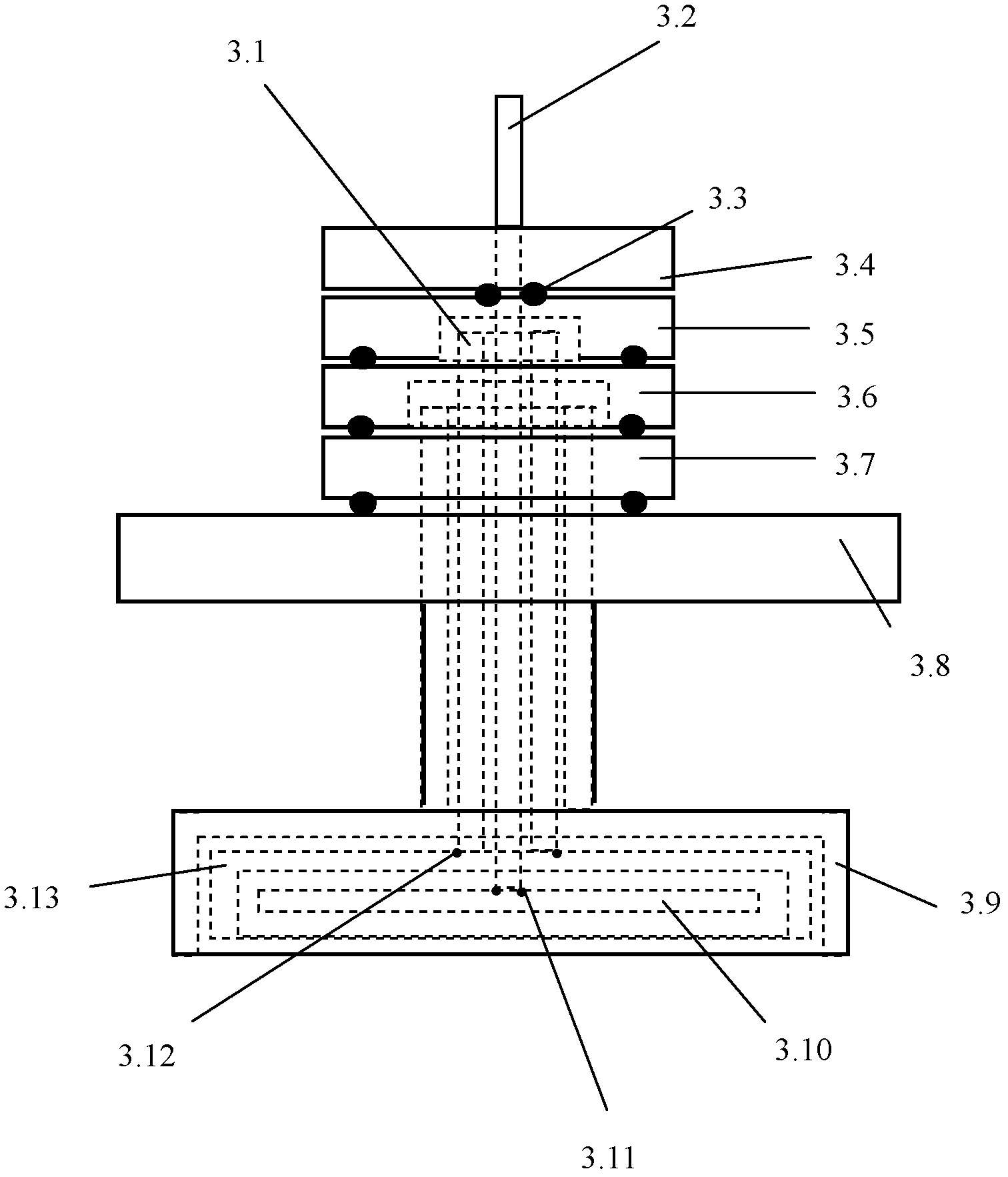

[0054] A plasma-enhanced chemical vapor deposition vacuum equipment of the present invention, its main structure block diagram is shown in figure 1 , it is a continuous structure with the same shape and structure. The structure is composed of left flange 1, main vacuum chamber 2, isolation plate 3, high vacuum sealing valve device 4, auxiliary vacuum chamber 5, right flange 6, and large sealing plate 7 arranged in sequence from left to right. , and so on for the rest. The sequence positions between them are as figure 1 As shown, the connection relationship is: the connection between the left flange 1 and the main vacuum chamber 2 is connected by argon arc welding; the connection between the main vacuum chamber 2 and the isolation plate 3 is connected by argon arc welding; the isolation plate 3 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com