Electrical Test Monitoring Feedback Chemical Vapor Deposition System and Its Application

A technology of chemical vapor deposition and monitoring feedback, which is applied in the field of chemical vapor deposition systems to achieve the effects of strong flexibility, good assembly and high temperature sealing performance, and strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

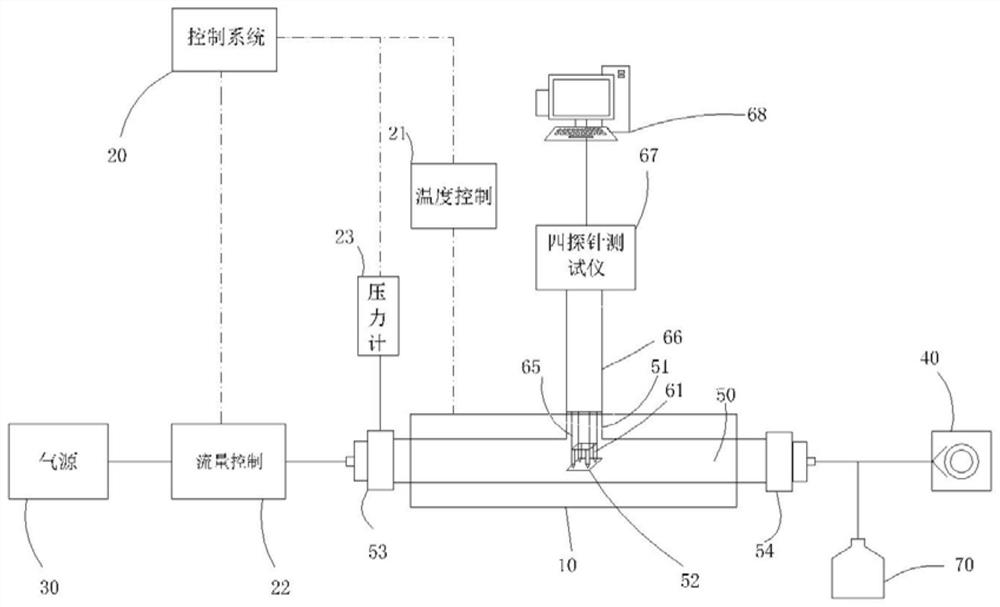

[0050] Equipment structure and connection mode of the present invention are:

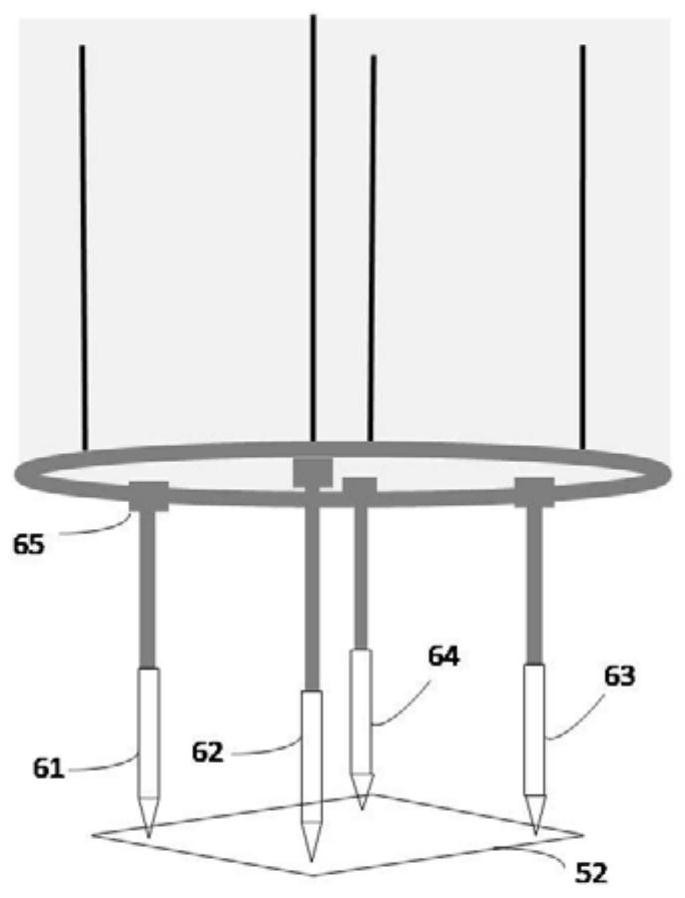

[0051] An electrical test monitoring feedback chemical vapor deposition system includes a chemical vapor deposition system and an electrical test system. Chemical vapor deposition system includes high temperature heating system, gas source system, vacuum system and tail gas treatment system. Such as figure 1 As shown, the high-temperature heating system includes a high-temperature furnace 10 and a furnace tube. The furnace tube is a three-way furnace tube 50, specifically a three-way quartz tube. A carrier made of ceramic material is arranged directly below the upper opening 51 of the three-way furnace tube 50. Sample stage, place SiO2 on the sample stage 2 / Si substrate 52 . The electrical test system includes a four-probe test rod 60 connected by built-in wires and a four-probe tester 67 , and the four-probe tester 67 is connected to an electrical test analysis system 68 . The four-probe test ...

Embodiment 2

[0062] An excellent property of graphene in terms of electron mobility is that its mobility hardly changes with temperature. The reason why electrons are affected by temperature is that electron mobility is reduced due to the scattering effect of lattice vibrations in electron transfer, and the strength of lattice vibrations is proportional to temperature, but the lattice vibrations of graphene seldom scatter electrons. , so it is hardly affected by temperature.

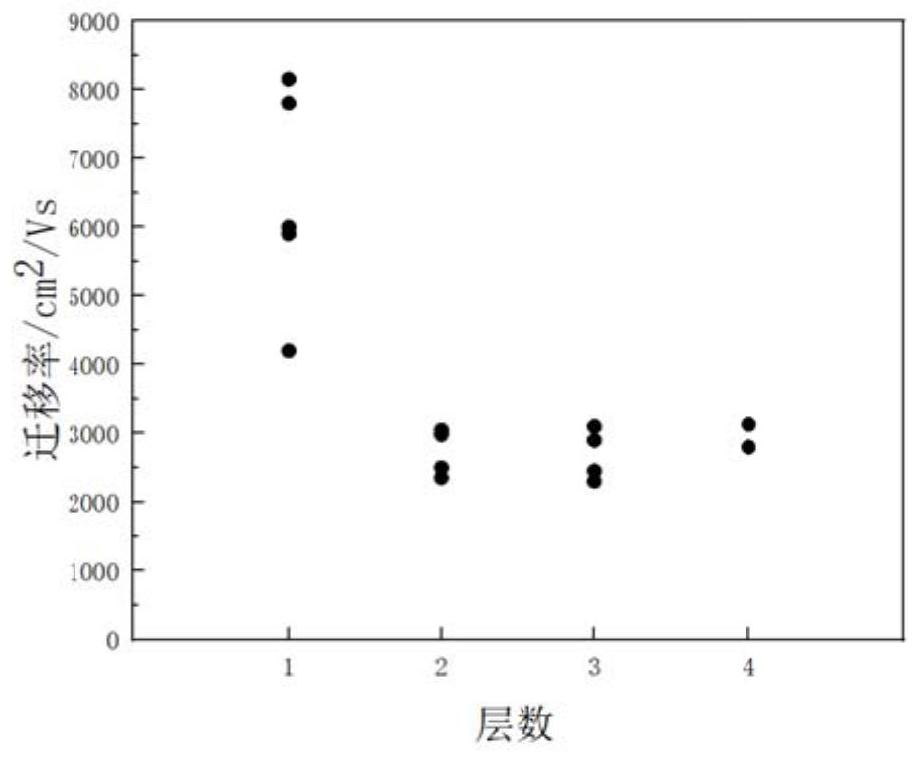

[0063] At the same time, the electrical properties of the graphene film are mainly determined by the number of layers. The current modulation increases monotonically with decreasing number of layers due to the decrease in interlayer scattering. When the number of layers is reduced from bilayer graphene to single-layer graphene, the mobility increases dramatically due to the inherent change from quadratic to linear dispersion relation, with the carrier mobility in a single layer being significantly greater than that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com