Method for reinforcing bridge structure separated steel-concrete combined truss

A technology of bridge structure and combined truss, which is applied in the bridge and structural engineering fields of civil engineering, and can solve the problems of beam surface flatness, high cleanliness requirements, poor durability, and insignificant improvement of FRP reinforced structure stiffness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

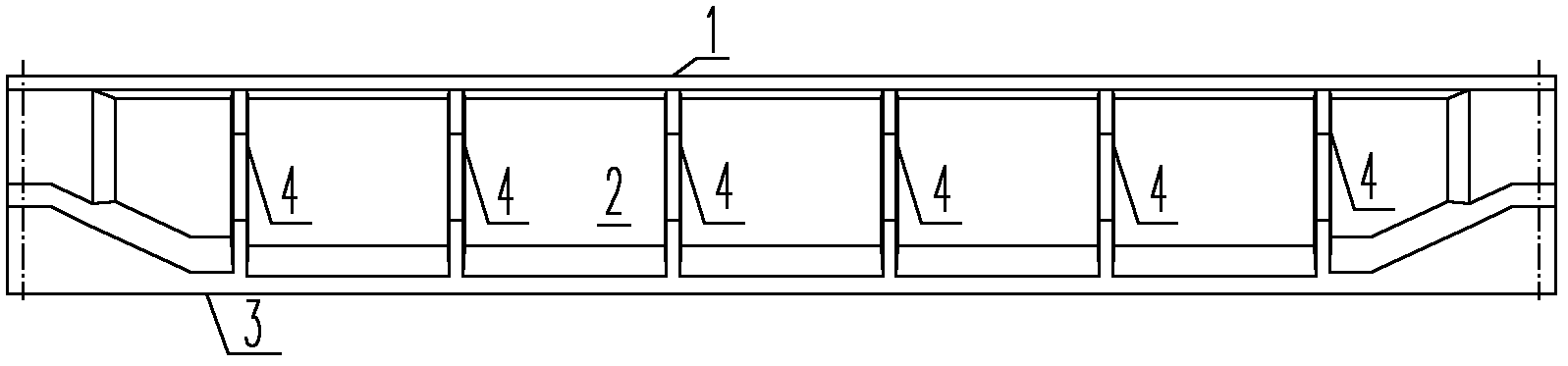

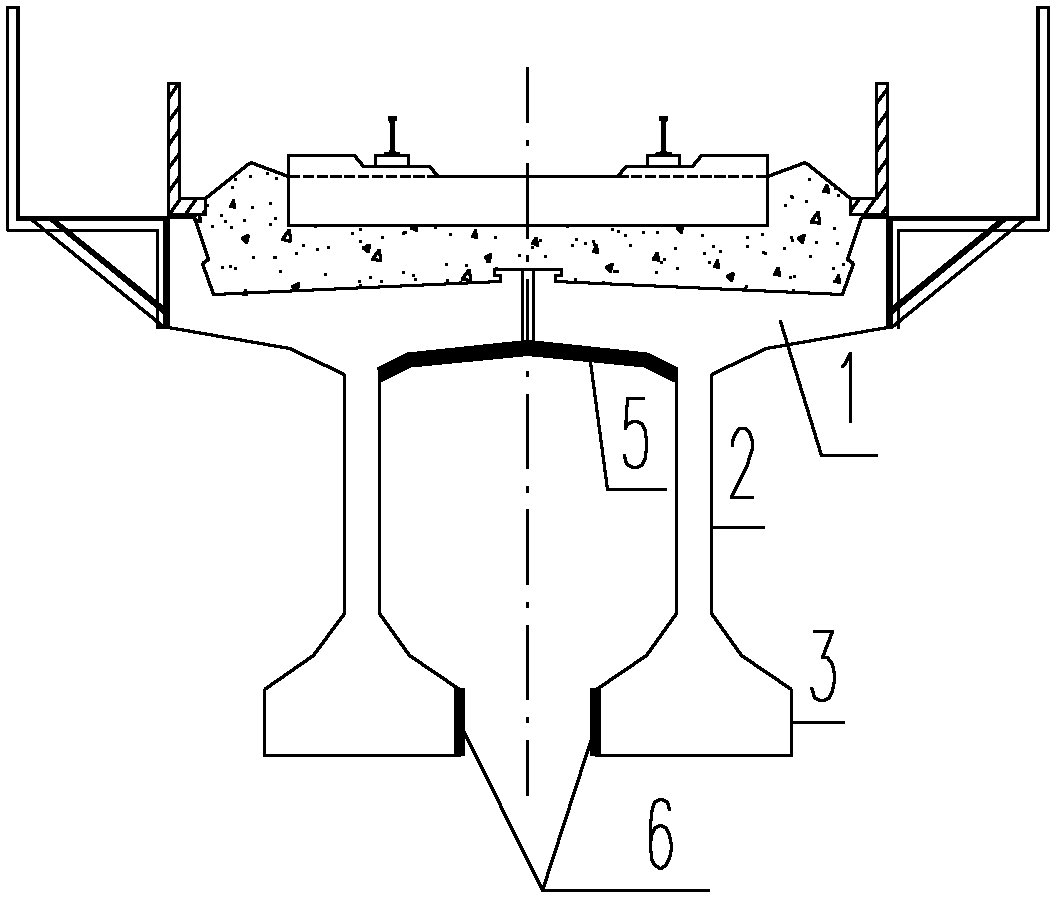

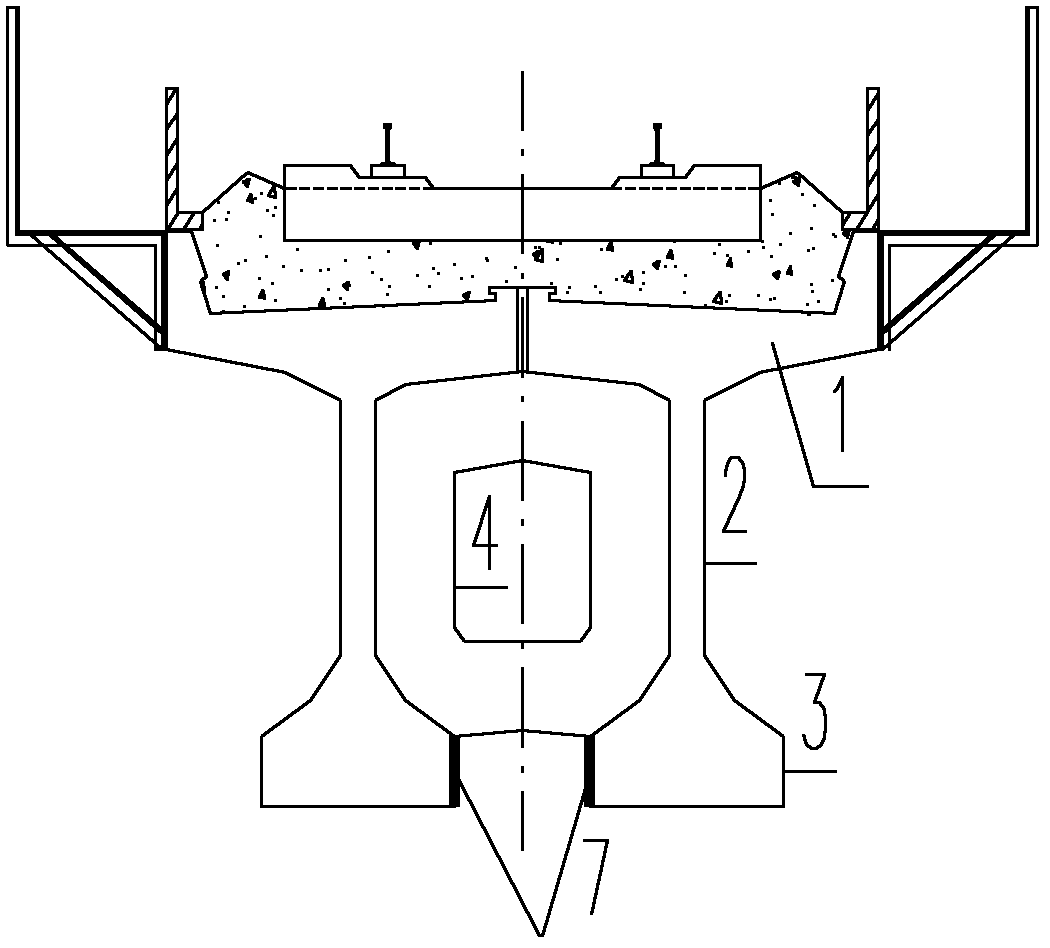

[0133] Preferred embodiments of the present invention are described below in conjunction with accompanying drawings, wherein reference numerals in the figure represent: 1-concrete T-beam top plate; 2-concrete T-beam web; 3-concrete T-beam bottom plate; 4-diaphragm; 5-reinforced interface of upper flange; 6-reinforced interface of lower flange; 7-reinforced interface of lower flange of diaphragm; 8-planted reinforcement; 9-bolt; 10-steel plate; Steel box girder; 13- low-height steel box girder diaphragm; 14- unbonded prestressed steel strand; 15- truss diagonal bar; 16- truss vertical bar; 17- gusset plate; 18- three-sided surrounding welding 19-hole steel plate; 20-through steel bar; 21-upper flange reinforced concrete; 22-lower flange reinforced concrete; 23-fulcrum anchor box; 24-concrete pier; 25-support.

[0134] The solution of the present invention is on the basis of the prior art to provide a rapid reinforcement construction technology of a novel bridge structure, the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com