Cavern-pile mechanical construction method for shallow subsurface excavated metro station at water-rich sandy stratum

A technology for shallow buried underground excavation and subway stations, which is applied in the direction of sheet pile walls, earthwork drilling and mining, and foundation structure engineering, etc., to achieve the effects of low construction strength, enhanced stability, and high construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

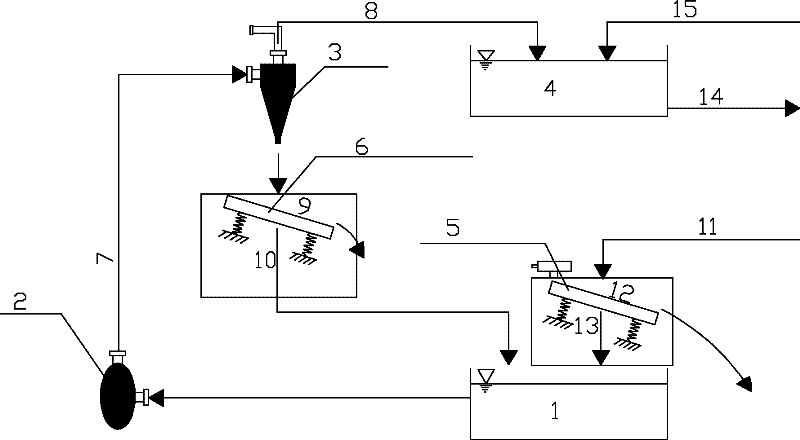

[0023] A mechanical construction method for tunnel piles in underground excavated subway stations in shallow buried water-rich sand layers, comprising the following steps:

[0024] (1) Lay P43 steel rails on both sides of the Φ800 pile line to form a track, which is convenient for moving construction in the drilling rig hole where the rail wheel is installed.

[0025] (2) Use a truck crane or a gantry crane to hang the modified drilling rig through the open-cut wellhead and move it into the pilot tunnel along the track.

[0026] (3) Position the drilling rig, connect the mud separation system, and perform drilling.

[0027] (4) After drilling and clearing the holes, lower the reinforcement cage in sections. Reinforcement cages are numbered and processed in sections, straight threaded sleeves are connected by positive and negative wires, and trial assembly in advance. When the reinforcement cage is lowered, the derrick is used for hoisting and installation, and a rice-shaped ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com