Roof ridge gusset and light steel structure thereof

A node and ridge technology, applied in truss structures, roofs, building components, etc., can solve the problems of increased bearing capacity and rigidity, difficult connection, etc., to achieve improved bearing capacity and stability, beautiful appearance, and overcome the large production workload. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

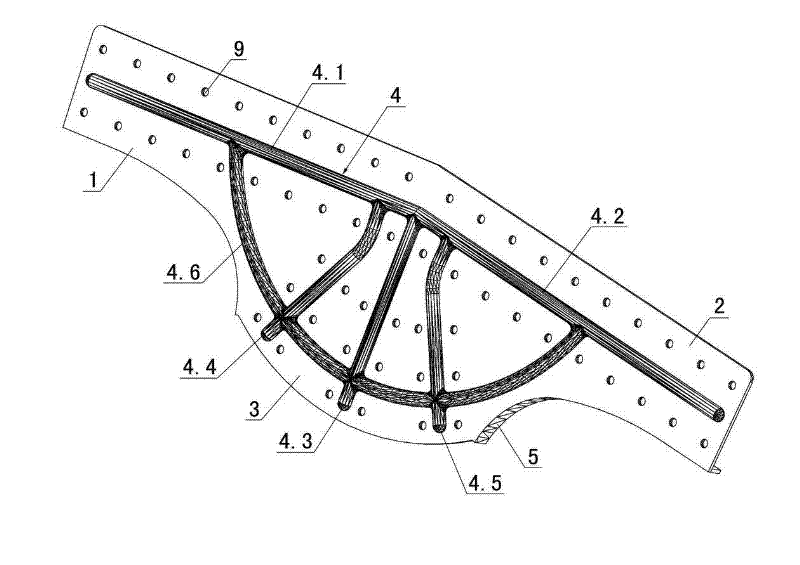

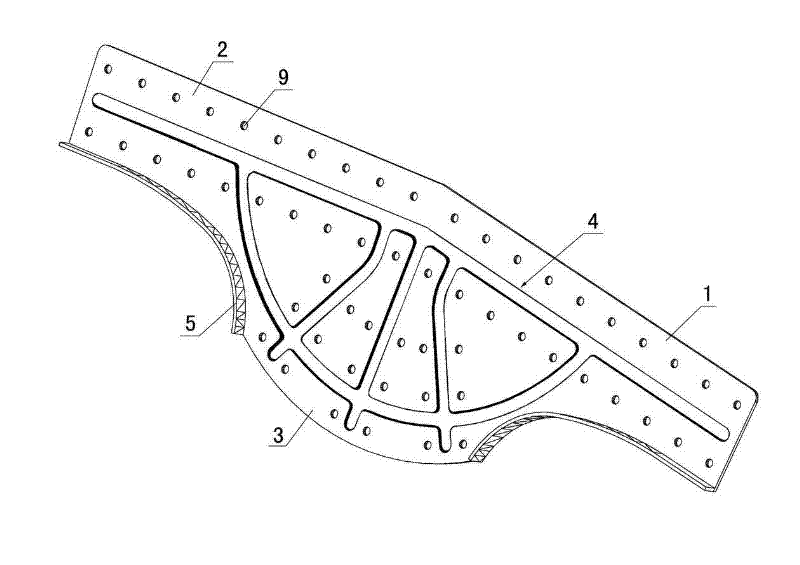

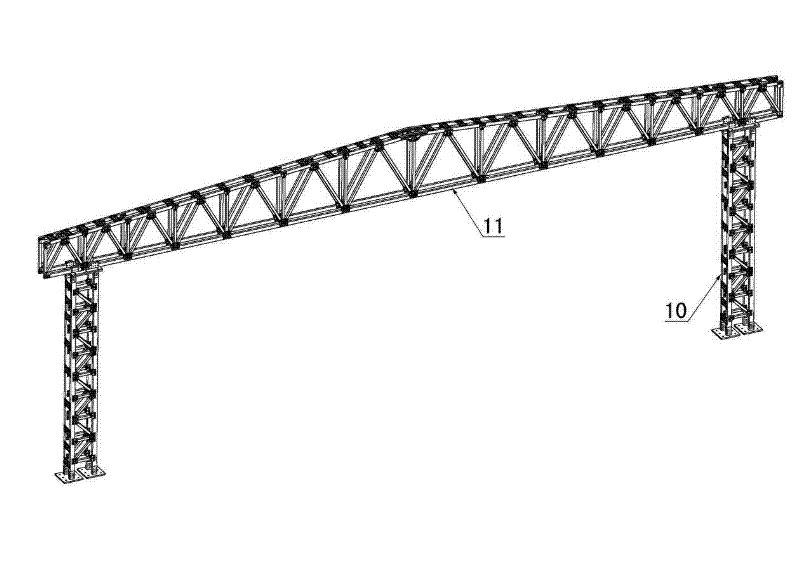

[0029] see figure 1 , figure 2 As shown, the plate body of this kind of ridge node gusset plate is stamped by metal thin-walled plate, and includes a plate-shaped whole with left chord connecting plate 1, right chord connecting plate 2 and web connecting plate 3 Connectors, the lower edge of the left chord connecting plate 1 to the side edge of the web connecting plate 3, the lower edge of the right chord connecting plate 2 to the side edge of the web connecting plate 3 are all provided with a The curved arc-shaped flanging 5 on the back of the metal thin-walled board is provided with a stamping bead 4 that protrudes toward the front of the metal thin-walled board and does not pass through the edge of the board body, and the board body is also provided with screw holes 9 .

[0030] The stamping bead 4 is composed of left vertical stamping bead 4.1, right vertical stamping bead 4.2, middle vertical stamping bead 4.3, left transverse stamping bead 4.4, right transverse stampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com