Buried type high-pressure water channel or tunnel seepage-resistant lining structure

A high-pressure waterway and buried technology, which is applied in tunnel lining, wellbore lining, tunnel, etc., can solve the problems of poor anti-seepage durability, water permeation instability, and poor anti-seepage performance, so as to achieve convenient operation and prevent buckling damage , The effect of reducing the project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the drawings.

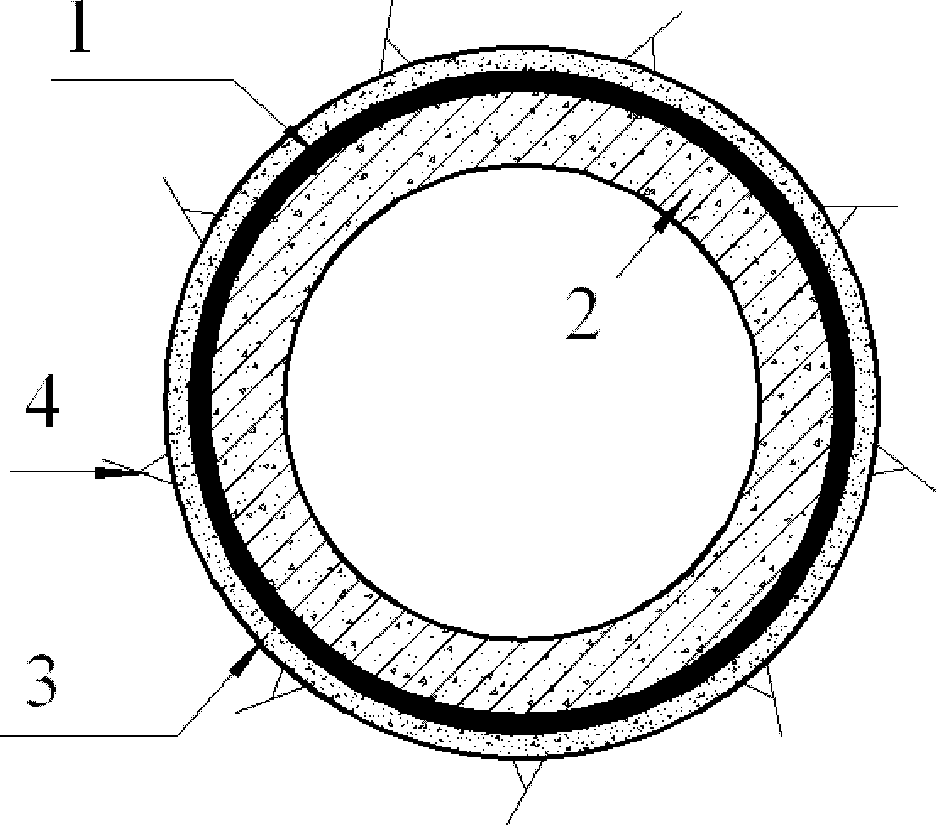

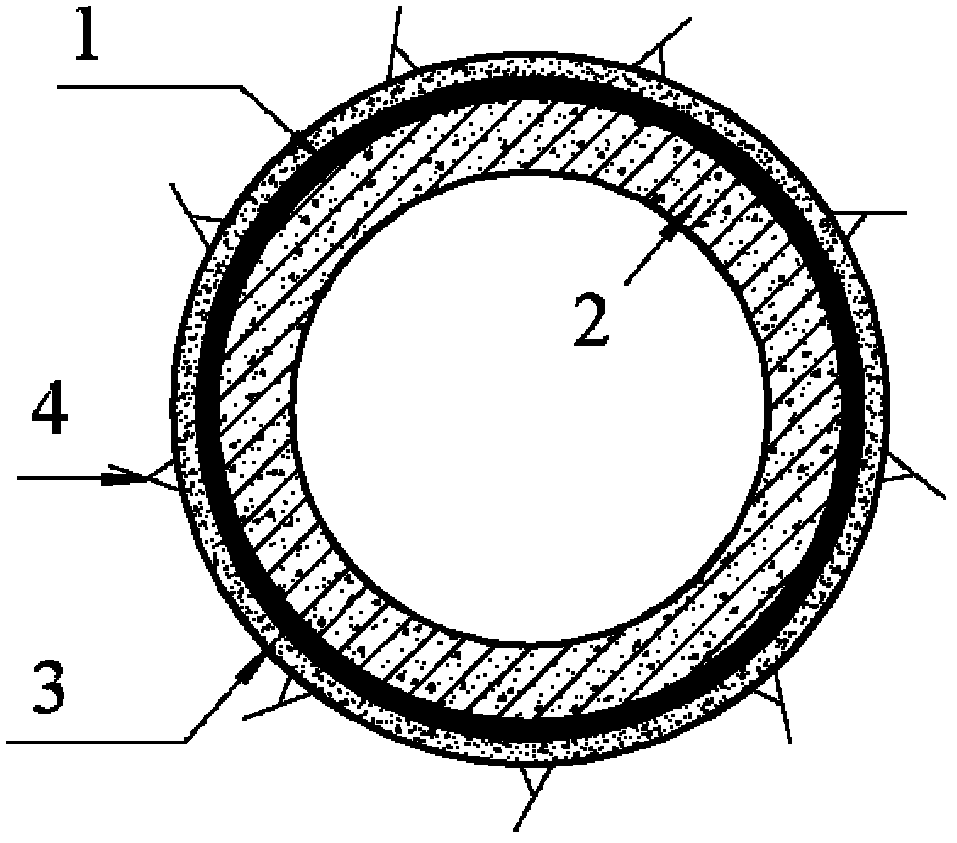

[0009] See figure 1 An anti-seepage steel pipe 1 is provided in the high-pressure pipeline section or high-pressure bifurcated pipe section 4, and leveling or backfill concrete 3 is arranged between the outer wall of the anti-seepage steel pipe 1 and the high-pressure pipe section or the high-pressure bifurcated pipe section 4. The inner wall is provided with reinforced concrete lining 2.

[0010] See figure 1 , By installing a certain thickness of reinforced concrete lining 2 in the anti-seepage steel pipe 1 to share the internal water pressure acting on the anti-seepage steel pipe 1 on the outer layer of reinforced concrete, so as to reduce the thickness of the anti-seepage steel pipe 1, and at the same time use the reinforced concrete lining 2 It has good compressive performance, resists the external water pressure transmitted through the outer steel pipe, completely avoids the occ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com