Calibration method for photolithography line width test

A calibration method and technology of lithographic line width, which is applied in the direction of measuring devices, instruments, and wave/particle radiation, can solve problems such as the inability to guarantee the accuracy of lithographic line width testing, and achieve the effect of avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

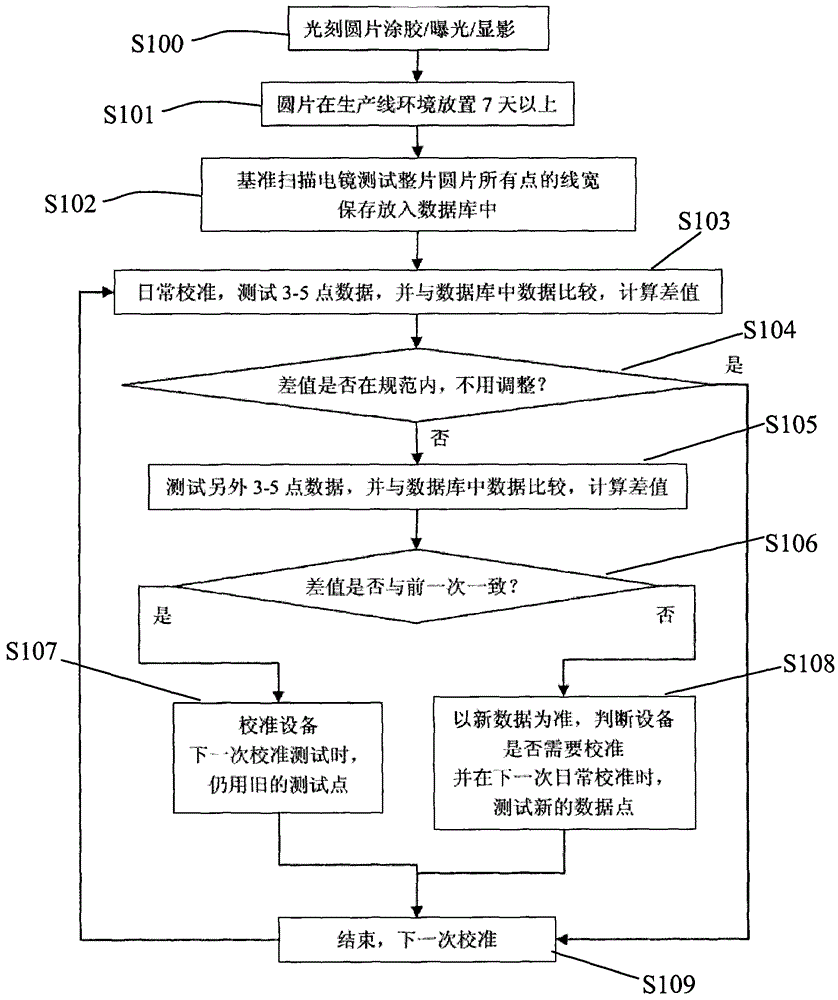

no. 1 approach

[0033] The first embodiment of the scanning electron microscope calibration of the present invention includes the following steps:

[0034] S100, gluing / exposure / development of the photolithography wafer;

[0035] S101. The wafer is placed in the production line environment for more than 7 days;

[0036] S102. The reference scanning electron microscope tests the line widths of all points on the entire wafer, and saves them in a database;

[0037] S103, daily calibration, test 3 to 5 points of data, compare with the data in the database, and calculate the difference;

[0038] S104. Determine whether the difference is within the specification and whether adjustment is required; if not, execute step S109, that is, end the current calibration, and proceed to the next calibration; if so, execute step 105;

[0039] S105. Test another 3 to 5 points of data, and compare with the data in the database, and calculate the difference;

[0040] S106, judging whether the difference is con...

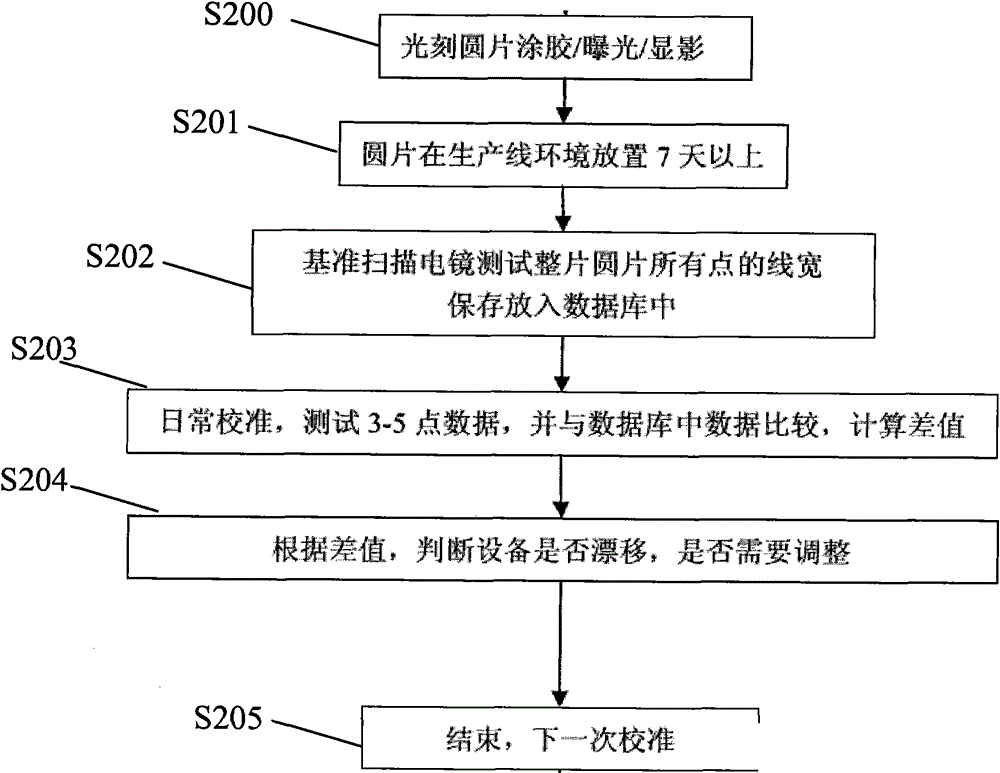

no. 2 approach

[0045] The second embodiment of the scanning electron microscope calibration of the present invention includes the following steps:

[0046] S200, gluing / exposure / development of photolithography wafer;

[0047] S201. The wafer is placed in the production line environment for more than 7 days;

[0048] S202. The reference scanning electron microscope tests the line widths of all points on the entire wafer, and saves them in a database;

[0049] S203, daily calibration, test 3 to 5 points of data, compare with the data in the database, and calculate the difference;

[0050] S204. According to the difference, determine whether the device drifts and whether adjustment is required; if adjustment is not required, proceed to S205;

[0051] S205. End the current calibration and start the next calibration, that is, repeat steps S203 and S204.

[0052] The test points for each calibration in the above process are different, and the appearance of the test points is not damaged, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com