Thermal mechanical fatigue test system for hollow air-cooled turbine blade

A thermo-mechanical fatigue, turbine blade technology, used in the testing of mechanical parts, the testing of machine/structural parts, measuring devices, etc., can solve the problems of nylon wear, large mechanical load, aging, etc., to reduce contact resistance, reliable mechanical load, effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

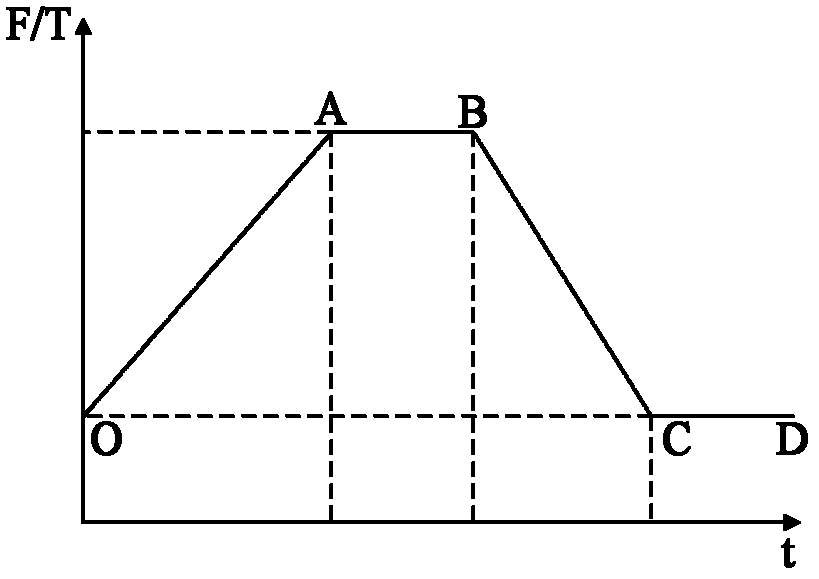

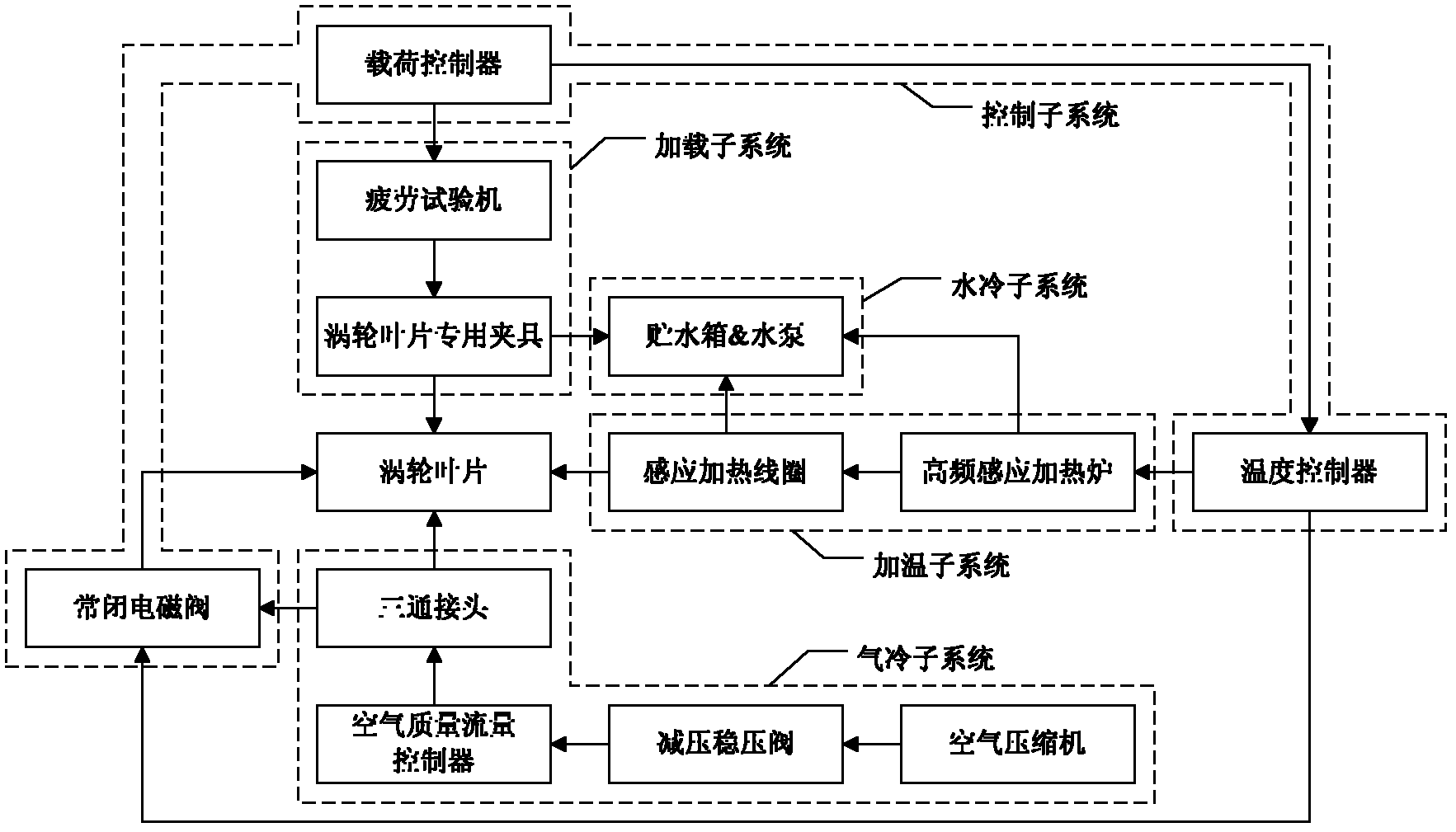

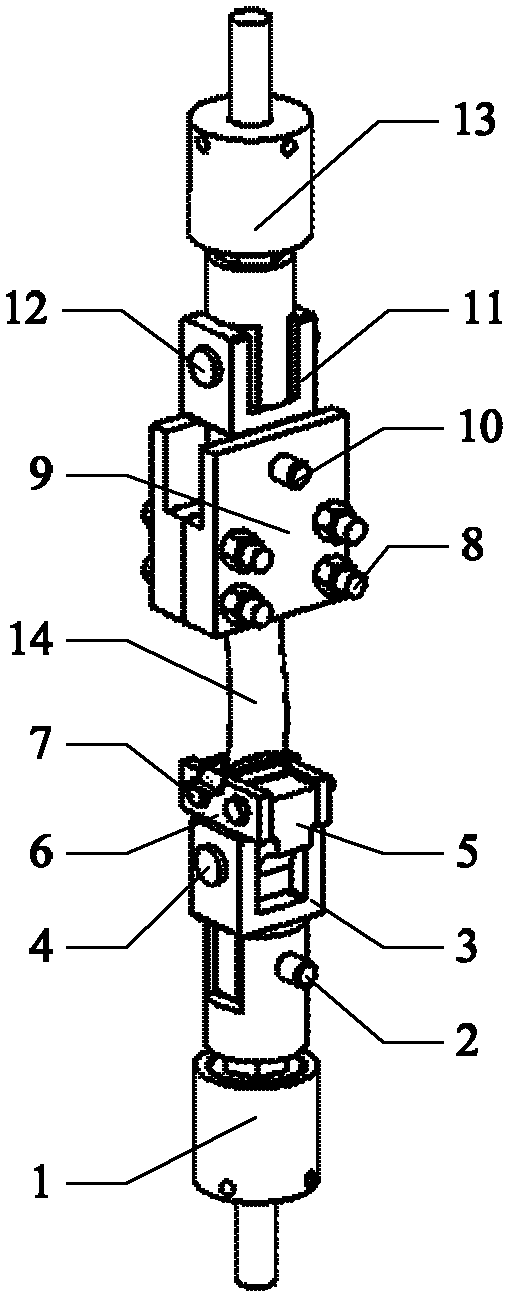

[0050] The following is a further description of the technical scheme adopted by a hollow air-cooled turbine blade thermomechanical fatigue test system of the present invention to realize the simulation of the work stress field, temperature field and load spectrum of the examination section in conjunction with the accompanying drawings. The load spectrum of the thermomechanical fatigue test of the hollow air-cooled turbine blade is as follows: figure 1 As shown, it is divided into four stages: loading (O-A), peak holding (A-B), unloading (B-C) and valley holding (C-D). The assessment section of the turbine blade is the middle section of the blade body. Through the finite element method, the working stress field and temperature field of the turbine blade examination section in the peak holding stage of the load spectrum are calculated, and this is used as the target of the stress field and temperature field simulation under the test conditions. The composition of the thermome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com