Preparation method for 2D70 aluminium alloy spectrum and chemical standard sample

A technology of standard samples and aluminum alloys, which is applied in the field of research and development of aluminum alloy standard samples, can solve problems such as insufficient standard samples of 2-series aluminum alloys, and achieve the effect of saving research and development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

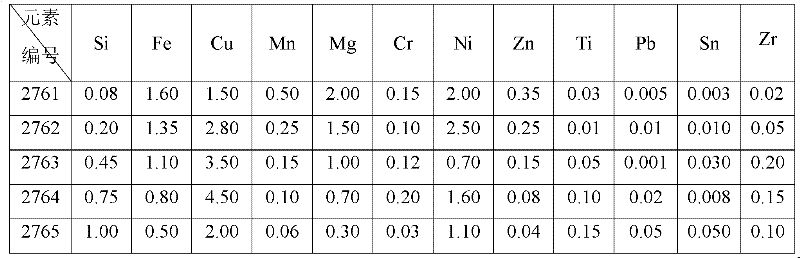

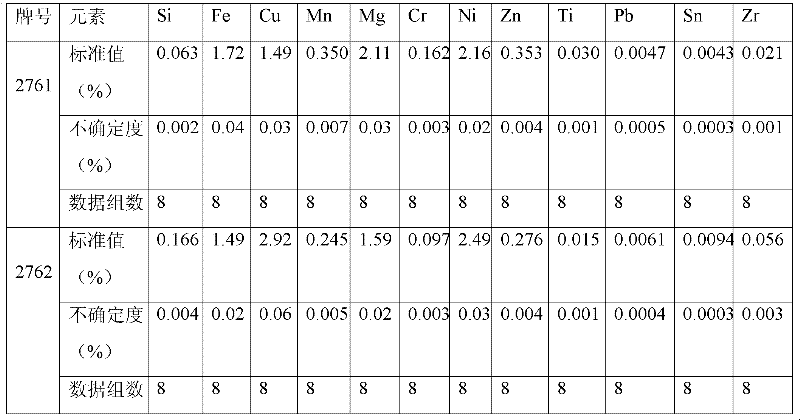

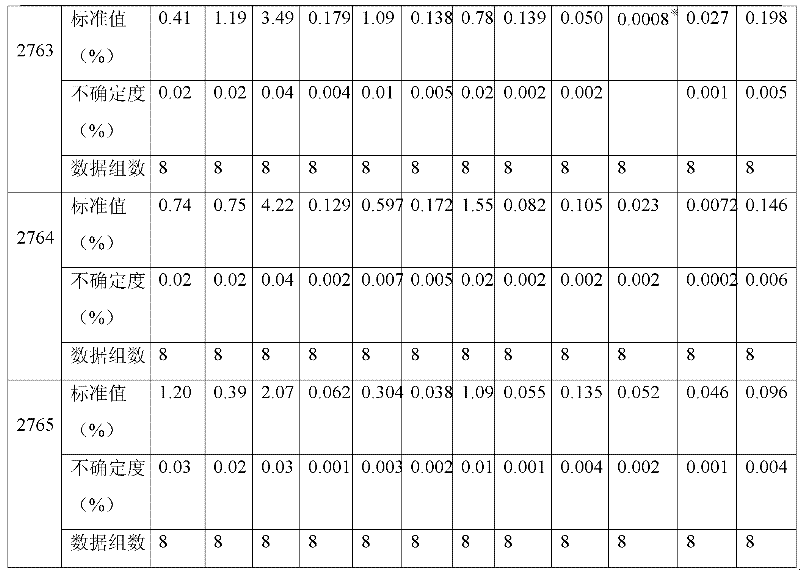

[0009] Specific embodiment 1: The 2D70 aluminum alloy spectrum and chemical standard sample preparation method of the present embodiment is carried out according to the following steps: 1. Weigh 2% to 3% of Cu powder and 0.1% to 0.3% of Mn powder by mass percentage , 0.5%~1% Si powder, 1%~1.5% Fe powder, 1%~1.5% Mg powder, 0.1%~0.15% Cr powder, 1%~2% Ni powder, 0.05%~0.1 % of Ti powder, 0.01% to 0.03% of Pb powder, 0.01% to 0.03% of Sn powder, 0.1% to 0.15% of Zr powder and the rest of aluminum powder; 2. Add the raw materials weighed in step 1 to the casting In the furnace, cast at a temperature of 700°C to 760°C, then perform heat treatment at a temperature of 450°C to 510°C, and cool at room temperature for 1 to 20 hours to obtain an ingot; 3. Perform a low-magnification inspection on the ingot obtained in step 2 and uniformity initial inspection; 4. Extrusion molding inspection: Spectral standard sample component uniformity inspection According to the standard sample techn...

specific Embodiment approach 2

[0013] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the Mg powder, Zn powder, Pb powder, Sn powder and Zr powder described in step one can also be selected for use with industrial pure magnesium, industrial pure zinc, Technically pure lead and technically pure tin and zirconium salts. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0014] Embodiment 3: This embodiment differs from Embodiments 1 to 2 in that the casting temperature in step 2 is 720-750°C. Others are the same as the specific embodiment 1 to 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com