D-type optical fiber based graphene electro-optical modulator and preparation method thereof

An electro-optic modulator and graphene technology, which is applied in the directions of instruments, optics, nonlinear optics, etc., can solve the problems of large coupling loss, difficult coupling between waveguide and optical fiber, etc., and achieve low insertion loss, avoid coupling problems, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

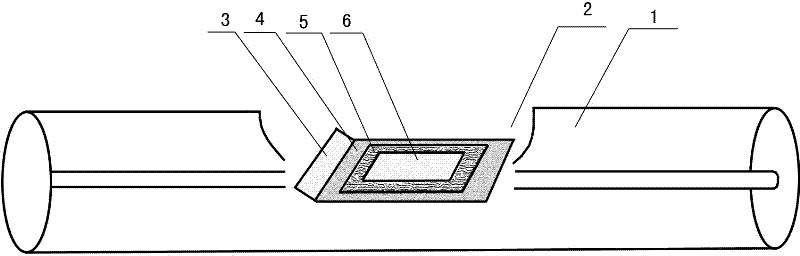

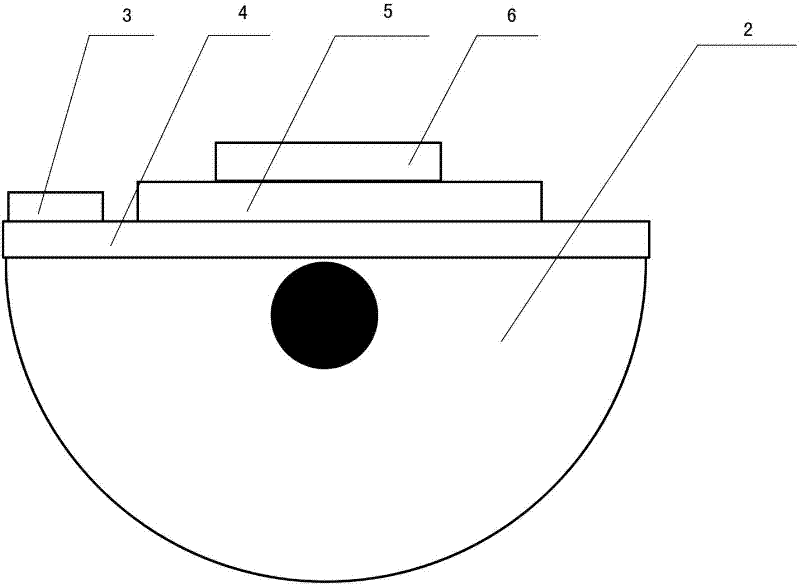

[0038] according to figure 1 , figure 2 , image 3 Shown, a kind of graphene electro-optic modulator based on D-type optical fiber, its preparation method has the following steps:

[0039] a. Preparation of D-type optical fiber:

[0040] First, use optical fiber strippers to remove the coating layer in the middle of a section of single-mode optical fiber 1 with a length of about 2 cm, and then use chemical corrosion to select a length of 1 cm in the middle of the single-mode optical fiber 1 that has been decoated, remove the cladding, and expose the core. outer;

[0041] b. Preparation of graphene film:

[0042] 1cm×1cm high-quality graphene 4 is prepared by chemical vapor deposition, and the growth substrate of graphene 4 is removed by chemical etching, so that graphene 4 floats on the surface of the solution;

[0043] c, the graphene film is transferred to the surface of the D-type optical fiber:

[0044] Use D-type optical fiber 2 as a new graphene 4 substrate, and t...

specific Embodiment approach

[0054] The specific implementation method is as follows: firstly, a section (about 1 cm long) of an ordinary single-mode optical fiber 1 is selected to remove the coating layer and the cladding, and a D-type optical fiber 2 is manufactured. Then the prepared graphene 4 film is transferred to the D-type optical fiber 2, so that the graphene 4 film completely covers the core of the D-type optical fiber 2. Therefore, the evanescent field of light leaked from the fiber core interacts with graphene 4, and the longer the graphene 4 is, the longer the interaction length between the light field and graphene 4 is, and the greater the absorption of the light field by graphene 4 is. Prepare a metal electrode 5 and a lead wire at one end of the graphene 4, and then coat a layer of Al on the graphene 4 film next to the metal electrode 3. 2 o 3 The insulating layer 5 is directly above the insulating layer 5, and the metal electrode 3 is plated and leads are added. Finally, the packaging te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com