Method for quickly positioning oscillation signal during complex chemical process

A chemical process, oscillating signal technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of poor system performance, difficult practical application, increased computational complexity, etc., to achieve enhanced security and no Downtime, easy operation, simple calculation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] The specific embodiment of the present invention will be further described below for a domestic factory that adopts Spheripol process polypropylene (PP) production process performance monitoring as an example.

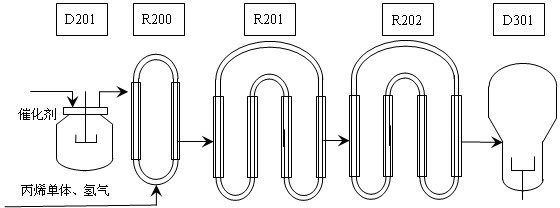

[0038] PP production process, a simple flow chart using a double-loop reactor is as follows figure 1 shown. Fresh catalyst (including cocatalyst TEAL and electron donor DONOR) is fed into the prepolymerization reactor R200 through the agitator D201, while fresh propylene monomer and inert component propane enter R200 through the circulation stream, and hydrogen is added to the circulation In stream. After pre-polymerization, the reactant product of reactor R200 is sent to loop reactor R201, where it is polymerized with fresh propylene monomer and hydrogen to form propylene polymer. The remaining unreacted liquid propylene in R201 is mixed with the polymer and enters the second loop reactor R202 to continue the reaction. The loop reactor outputs the mixture c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com