Method for realizing Fermi level de-pinning on surface of germanium substrate in metal- germanium contact

A Fermi level, germanium substrate technology, applied in the field of microelectronics, can solve the problems of carrier tunneling, low additional resistance, etc., and achieve small additional resistance, low conduction band offset, and good depinning effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is further described below by specific processing steps:

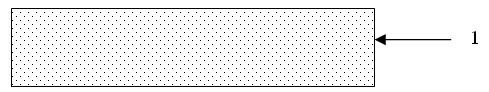

[0023] 1. Based on the n-Ge (100) substrate sheet with a resistivity of 0.05 Ω cm, rinse with HF with a concentration of 0.5%, followed by rinsing with deionized water for 5 minutes;

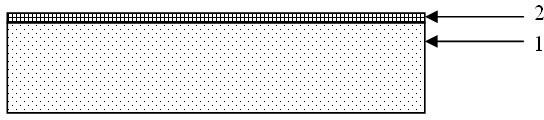

[0024] 2. Load the rinsed germanium substrate with a clean surface into the ALD cavity, and use the NH produced by the inductively coupled plasma source 3 Surface treatment of germanium substrates by plasma, chamber temperature 250°C, NH 3 Air pressure 5×10 -3 mbar, processing time 30s, radio frequency 200W, and finally form GeO of about 1nm x N y (x=0.92, y=0.08) ultra-thin dielectric layer;

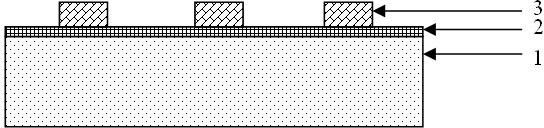

[0025] 3. With the help of a mask, use PVD technology to deposit a circular metal Al electrode with a vacuum of 10 -5 Pa, deposition power 150W, deposition time 3000s, electrode thickness 50nm, electrode diameter 500um.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com