Conductive connection material, method for connection between terminals and method for manufacturing connecting terminal

A technology of conductive connection material and resin composition, which is applied in conductive connection, electrical component connection, printed circuit manufacturing, etc., can solve the problems of insufficient contact, high cost of solder ball production, difficulty in agglomeration of conductive particles, etc., and achieve high insulation. Reliability, simple method, effect of good electrical connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

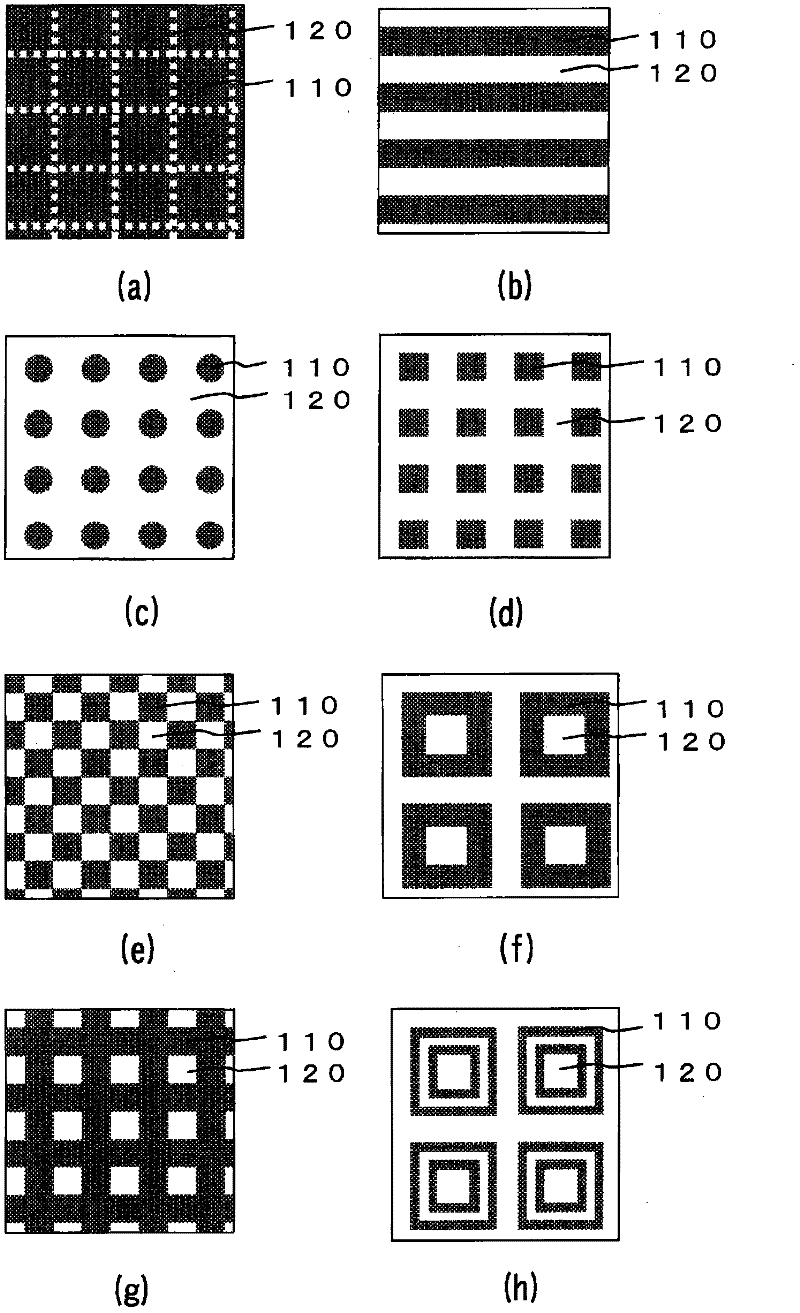

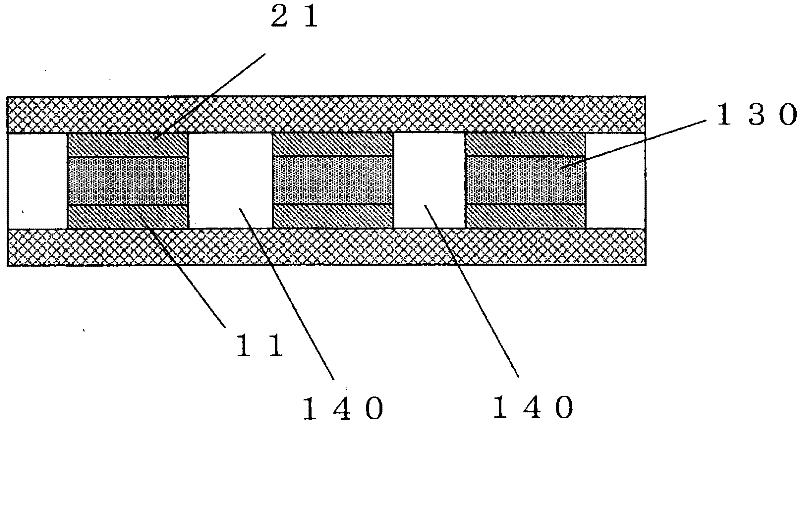

[0198] The method for connecting terminals according to the first embodiment of the present invention includes: an arranging step of arranging the conductive connecting material containing the aforementioned curable resin composition and metal foil between terminals; and heating the conductive connection material at a temperature at which the curing of the curable resin composition does not end; and a curing step of curing the curable resin composition.

[0199] In this connection method, heat-melted solder or tin is selectively aggregated between terminals to form a conductive region, and a curable resin composition is used to form an insulating region around it. As a result, insulation between adjacent terminals can be ensured to prevent leakage current, and therefore connection reliability between terminals can be improved. In addition, electrical connection between a plurality of terminals can be performed at one time also in a fine wiring circuit. Furthermore, by curing ...

no. 2 approach

[0213] Next, a connection method between terminals according to a second embodiment of the present invention will be described. The method for connecting terminals according to the second embodiment of the present invention includes: an arranging step of arranging a conductive connecting material containing the aforementioned thermoplastic resin composition and metal foil between opposing terminals; a heating step of arranging the aforementioned metal foil heating the conductive connecting material at a temperature above the melting point of the above-mentioned thermoplastic resin composition; and curing the thermoplastic resin composition. Next, each step will be described.

[0214] (a) Configuration process

[0215] In the case of using a conductive connecting material containing a thermoplastic resin composition and a metal foil, the conductive connecting material can also be disposed in the same manner as in the case of using a conductive connecting material containing a ...

Embodiment 1~9

[0260] (1) Preparation of curable resin composition

[0261] Each component shown in Table 1 was dissolved in methyl ethyl ketone (MEK) to obtain a varnish of a resin composition having a resin solid content of 40%. The obtained varnish was coated on a polyester sheet using a comma coater, and dried at 90° C. for 5 minutes to obtain a film-like curable resin composition having a thickness of 30 μm.

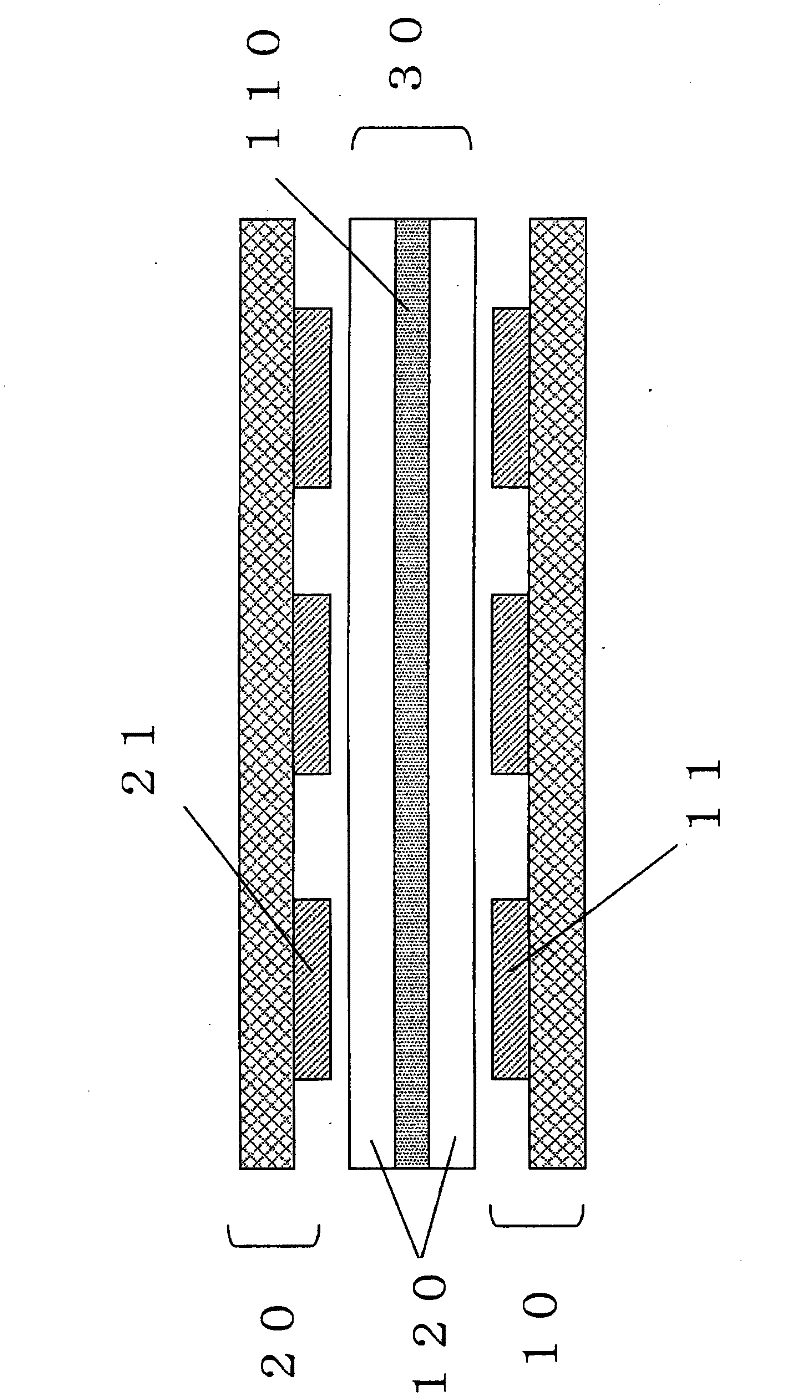

[0262] (2) Manufacture of conductive connecting materials

[0263] Under the conditions of 60° C., 0.3 MPa, and 0.3 m / min, the obtained film-like curable resin composition was laminated on both surfaces of the solder foil shown in Table 1 to manufacture a 70 μm-thick conductive connecting material.

[0264] (3) Connection between terminals

[0265] Next, terminal-to-terminal connection of the substrate was performed using the obtained conductive connecting material. As the substrate, an FR-4 base material (thickness: 0.1 mm) and a circuit layer (copper circuit, thickness: 12 μm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com