Carbonizing tank with atomizing device for soda water machine

A technology of atomization device and soda water, applied in beverage preparation devices, household appliances, kitchen appliances, etc., can solve the problems of small water flow, long water injection time, high water inlet pressure, etc., to prolong the contact time, ensure the carbonization effect, Avoid direct impact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

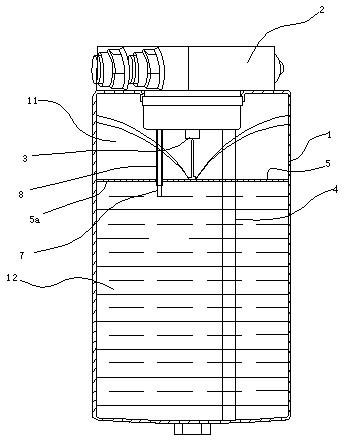

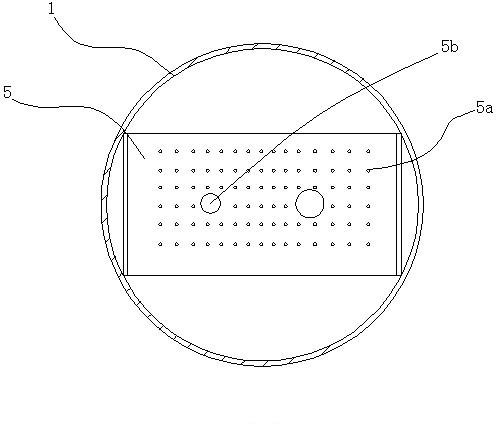

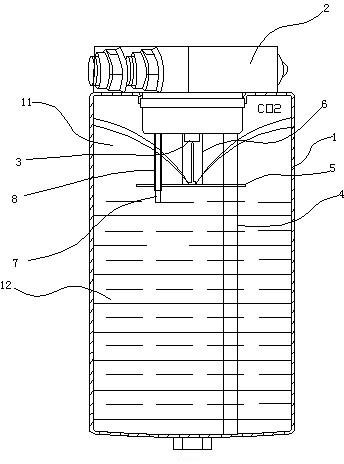

[0020] A carbonation tank for a soda water machine with an atomization device, comprising a tank body 1 with an upper opening, a combination valve 2 is arranged at the opening of the tank body 1, and the combination valve 2 is communicated with a nozzle 3 and an outlet pipe 4, the A water baffle 5 is arranged inside the pipe body 1, and the water baffle 5 is fixedly installed under the combination valve 2 through a connector 6, and the water baffle 5 separates the interior of the tank body 1 for accommodating An upper space 11 for carbon dioxide gas and a lower space 12 for accommodating water, there is an overflow channel between the upper space 11 and the lower space 12, and the plate surface of the water retaining plate 5 faces the nozzle 3 Outlet.

[0021] In this embodiment, the above-mentioned overflow channel is formed in such a way: the area of the water retaining plate 5 is smaller than the cross-sectional area of the tank body 1 so that the distance between the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com