Method of continuous evaporation crystallization and production method of anhydrous citric acid crystal

An anhydrous citric acid, evaporative crystallization technology, applied in evaporation, separation method, solution crystallization and other directions, can solve the problems such as small particle size of anhydrous citric acid crystal products, easy agglomeration of anhydrous citric acid crystal products, and inability to remove moisture. , to achieve the effect of reducing aggregation, increasing particle size and improving anti-caking performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

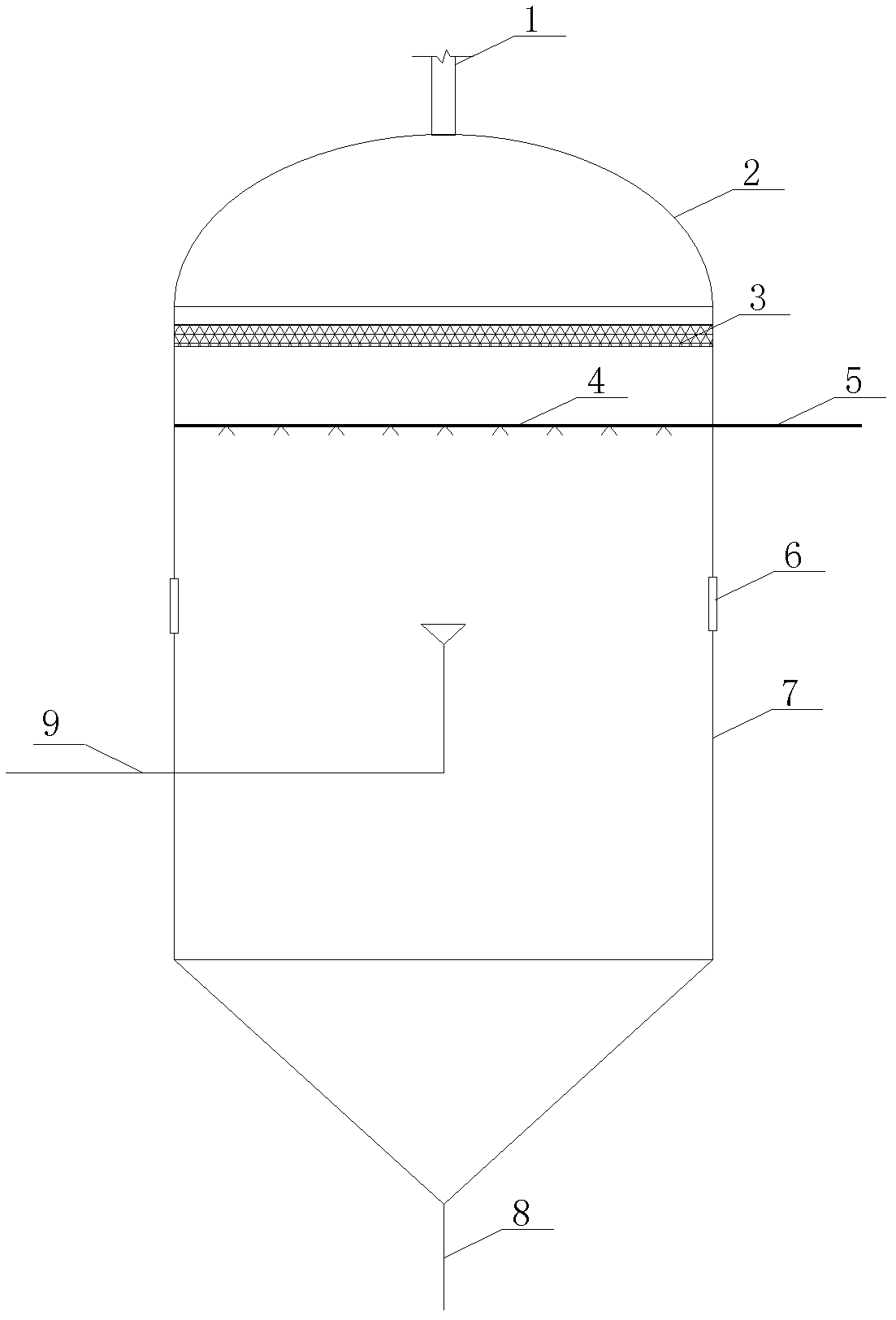

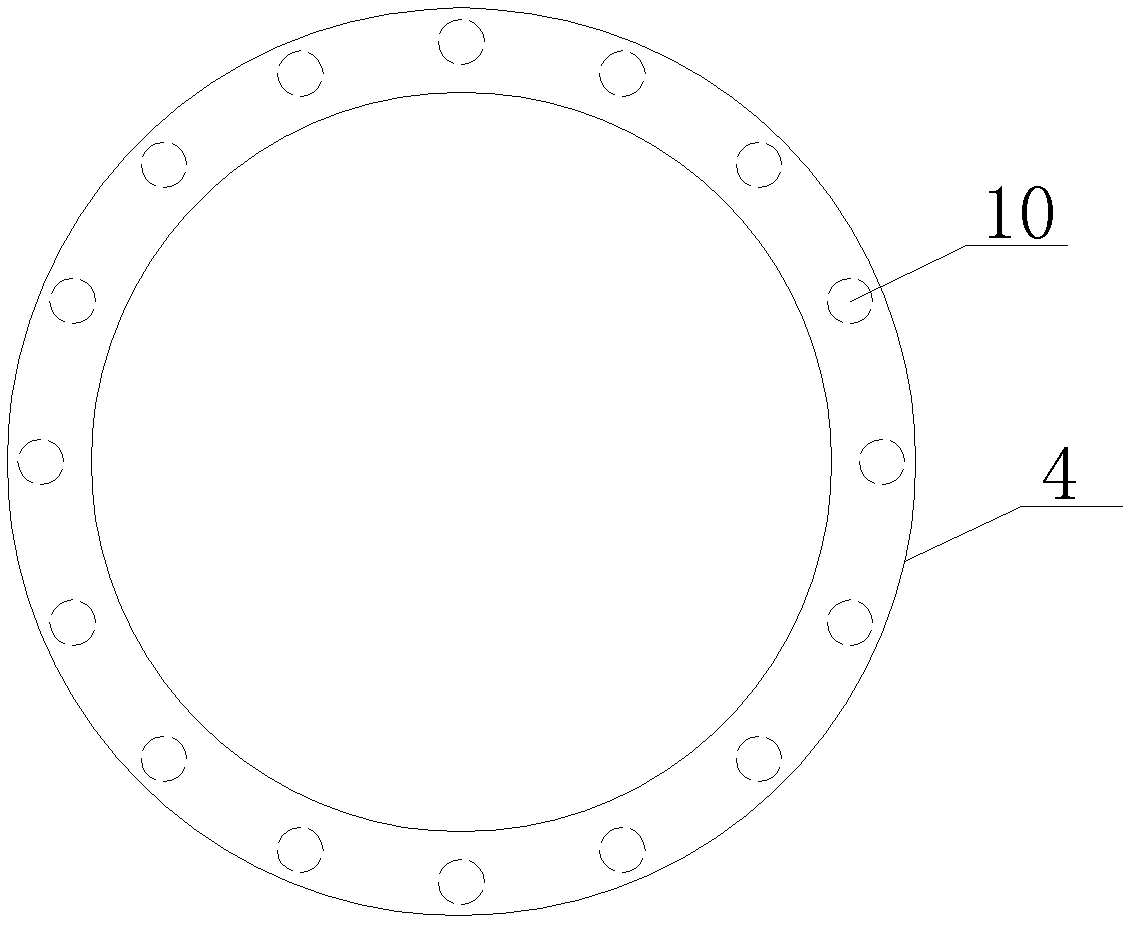

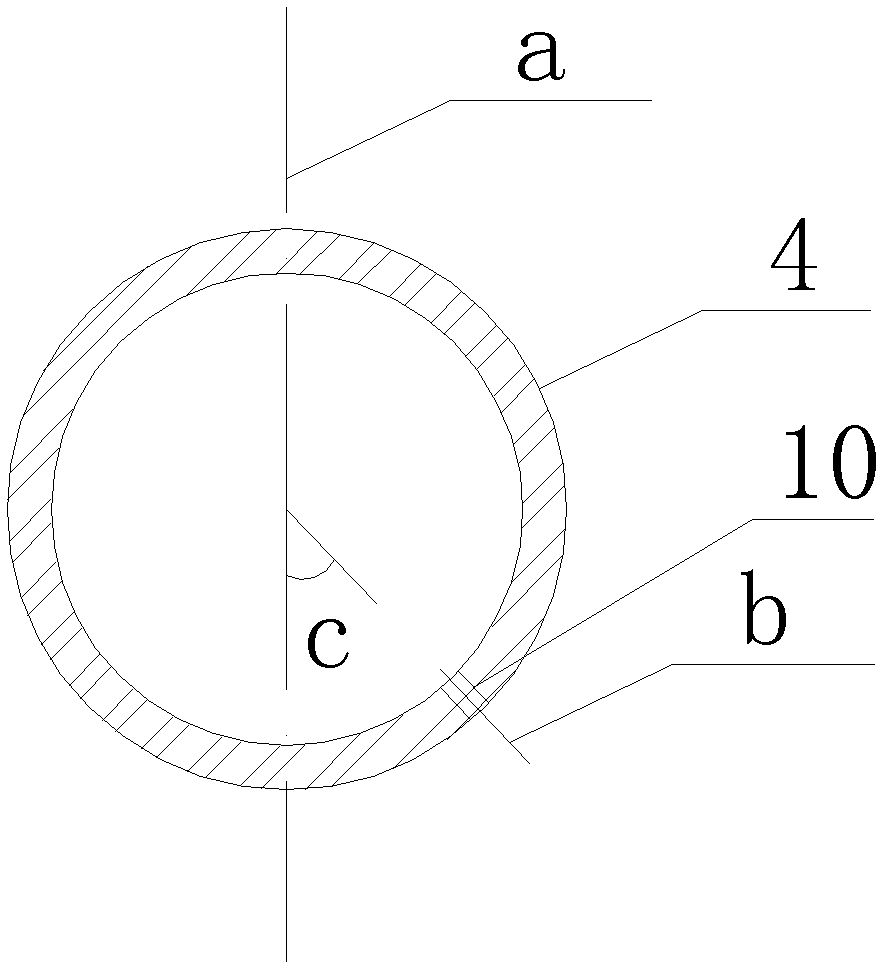

[0048] use figure 1 The crystallizer shown, wherein the cavity 7 volume is 18m 3 , inner diameter D=2.2m, height H=6m, crystal discharge port 8 is positioned at the bottom of cavity 7, and viewing mirror 6 is positioned at the top of crystal discharge port 8, is 3.5m apart from the 8 heights of crystal discharge port; The port 5 is located above the viewing mirror 6, and the height from the crystal discharge port 8 is 4.2m; the wire mesh demister 3 is located above the feed port 5, and the height from the crystal discharge port 8 is 4.9m. The annular pipe 4 made of stainless steel 316L communicates with the feed port 5, and is horizontally arranged in the cavity 7 along the inner surface of the crystallizer. The inner diameter of the annular pipe 4 is d=50mm. A hole-like structure 10 is provided every 65 mm in the axial direction. The hole-like structure 10 is a round hole with a diameter of 5 mm. The opening direction of the hole-like structure 10 faces the inner surface of ...

Embodiment 2

[0068] Using the crystallizer of Example 1, the difference is that the opening direction of the hole structure 10 faces the inner surface of the cavity 7, and the angle between the axis a of the hole perpendicular to the hole plane and the axis b of the cavity is 30°. Pass the test, when the distance is 3-9m from the ring pipe 4 3 When water is added at a flow rate of / h, it can be visually observed that the water flows down in the form of a liquid film along the inner wall of the cavity 7 .

[0069] The citric acid content is 60% by weight, the citric acid purity is greater than 99% by weight, and the density is 1264kg / m 3 The citric acid solution is pumped into the effective volume of 15m 3 The annular pipe 4 above the crystallizer, the solution is 4.6m 3 The flow rate of / h is continuously rinsed from the hole-like structure 10 in the annular pipe 4 along the inner wall of the cavity 7 and enters the crystallizer for evaporation and crystallization. It is 60 ℃ that the t...

Embodiment 3

[0073] The same crystallizer as in Example 1 was used.

[0074] The citric acid content is 57% by weight, the citric acid purity is greater than 99% by weight, and the density is 1248kg / m 3 The citric acid solution is pumped into the effective volume of 15m 3 The annular pipe 4 above the crystallizer, the solution is 5.388m 3 The flow rate of / h is continuously rinsed from the hole-like structure 10 in the annular pipe 4 along the inner wall of the cavity 7 and enters the crystallizer for evaporation and crystallization. It is 60 ℃ that the temperature is set in the crystallizer, and vacuum is-90kPa, when the citric acid content in the citric acid solution is 76% by weight (the citric acid solution that has passed into the citric acid content of this moment is 57% by weight is 21.94m 3 ), add 80-200 order anhydrous citric acid seed crystal 10kg in this citric acid solution (corresponding to degree of supersaturation 1.1), maintain 1 hour then, when solid content accounts for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com