Solid-liquid separation device

A technology of solid-liquid separation and filtration mechanism, which is applied in filtration separation, separation methods, chemical instruments and methods, etc., and can solve the problem that the cyclone cannot be processed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

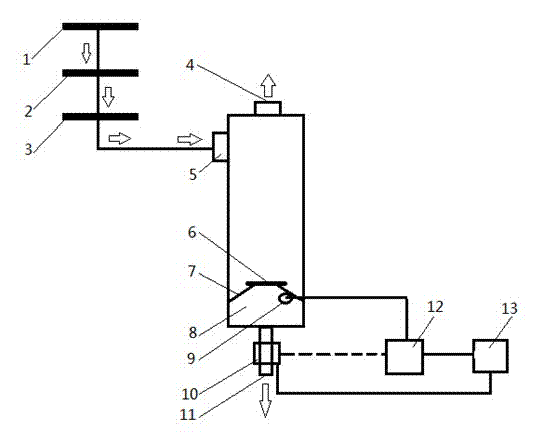

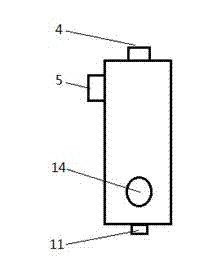

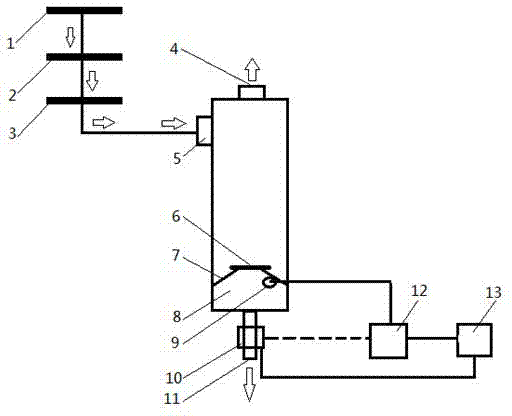

[0006] refer to Figure 1-Figure 2 , the solid-liquid separation device includes a cyclone mechanism, an auxiliary filtering mechanism, and an automatic sewage discharge control mechanism. ), the observation room (14), the dirt storage room (8) is provided with a support (7) and a spinning disk (6), and the auxiliary filter mechanism includes a primary filter screen (1), a secondary filter screen (2) , three-stage filter screen (3), the automatic sewage control mechanism includes a sensor (9), a control unit (12), a control valve (10), the sensor (9) is located on the bracket (7), and the control valve (10) is an electromagnetic The control valve also includes a power supply (13) that provides electricity for the control unit (12) and the control valve (10). The automatic control mechanism is also provided with a pneumatic control valve and an air source for providing compressed gas for the pneumatic control valve.

[0007] The present invention is applied to the working con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com