Method for preparing solid phase micro-extraction fiber by self-assembling graphene coating on metal wire layer by layer

A layer-by-layer self-assembly and fiber extraction technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of graphene easy to fall off, short service life, etc., achieve excellent adsorption performance, improve mechanical strength, and improve fragility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Preparation of layer-by-layer self-assembled graphene-coated stainless steel wire solid-phase microextraction fiber

[0024] Include the following steps A and B in turn:

[0025] A. Electroless silver plating on the surface of stainless steel wire

[0026] After the surface of the stainless steel wire is polished with fine sandpaper, it is washed with water and ethanol in sequence to remove impurities on the surface and increase the surface area. Put the treated stainless steel wire into the mixed solution of silver ammonia solution and glucose solution, the molar ratio of silver ammonia ion and glucose is 1:0.5, the mass concentration of glucose is 30%, react at room temperature for 2 hours.

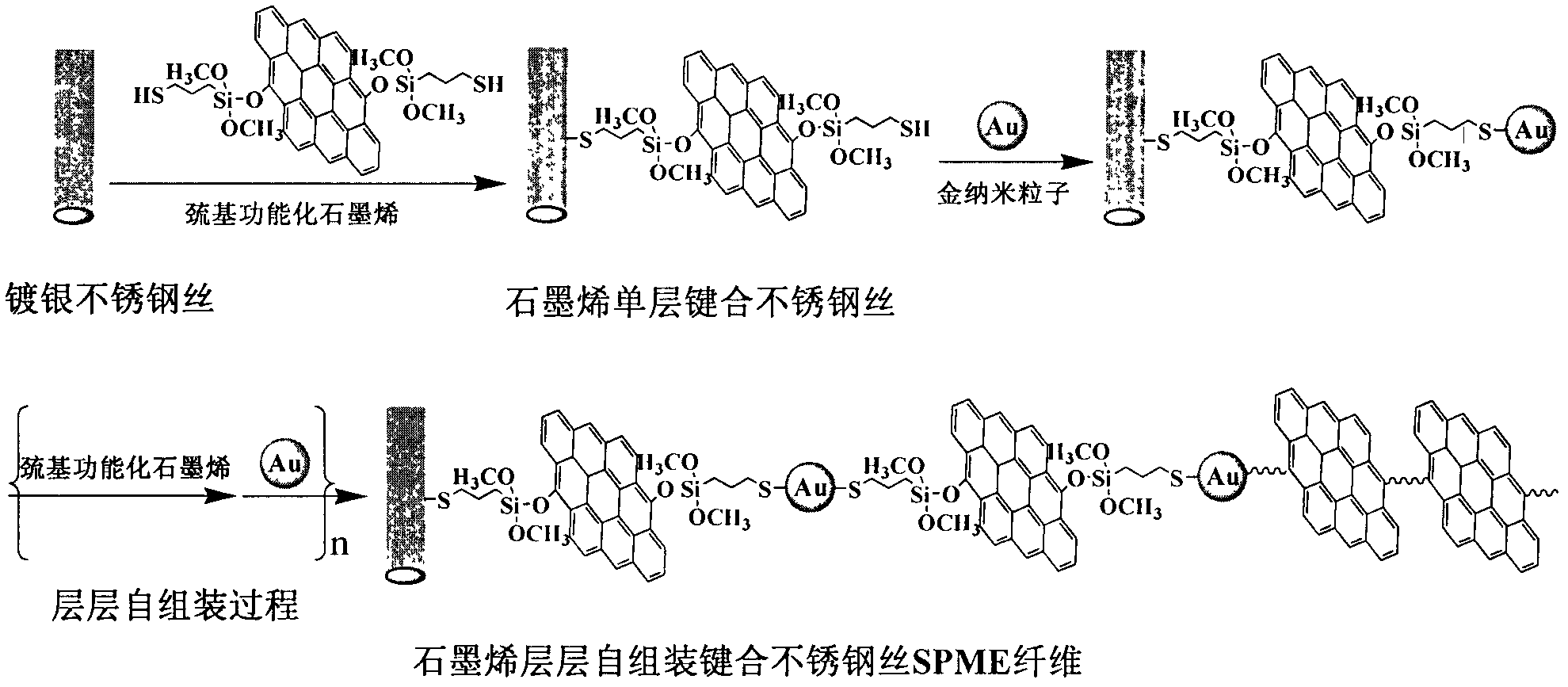

[0027] B. Preparation of layer-by-layer self-assembled graphene coatings

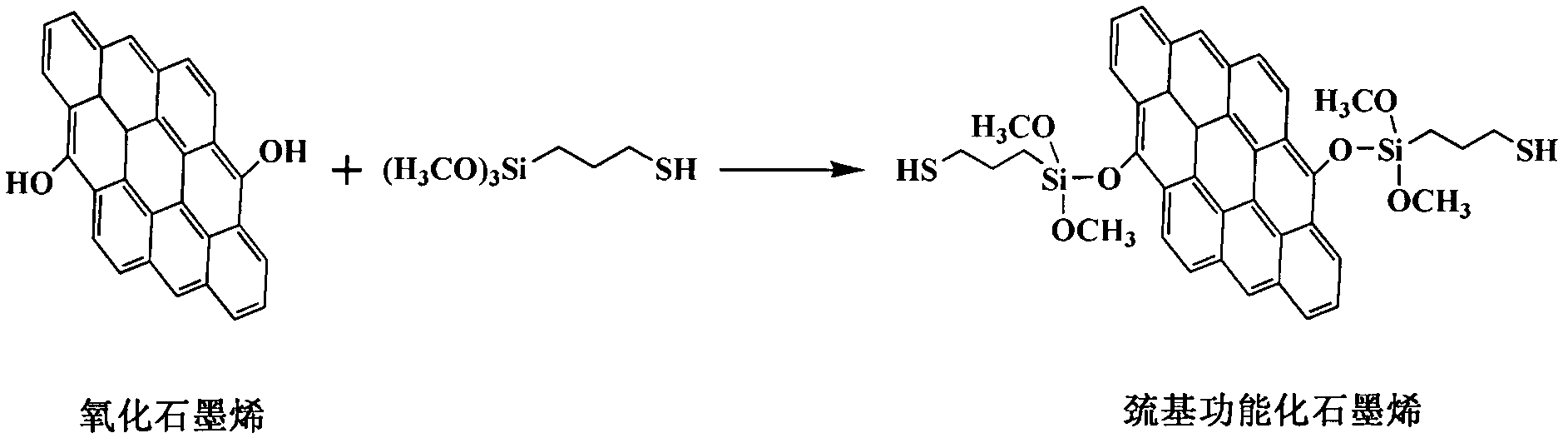

[0028] Graphene oxide with a mass ratio of 1:1 reacted with mercaptopropyltrimethoxysilane at 120° C. under nitrogen protection for 6 hours, and obtained mercapto-functionalized graphene (such...

Embodiment 2

[0029] Example 2: Preparation of layer-by-layer self-assembled graphene-coated titanium wire solid-phase microextraction fiber

[0030] Include the following steps A and B in turn:

[0031] A. Electroless silver plating on the surface of titanium wire

[0032] After the surface of the titanium wire is polished with fine sandpaper, it is washed with water and ethanol in sequence to remove impurities on the surface and increase the surface area. Put the treated titanium wire into the mixed solution of silver ammonia solution and glucose solution, the molar ratio of silver ammonia ion and glucose is 1:3, the mass concentration of glucose is 5%, and react at room temperature for 1 hour.

[0033] B. Preparation of layer-by-layer self-assembled graphene coatings

[0034] Graphene oxide with a mass ratio of 1:10 was reacted with mercaptopropyltrimethoxysilane at 80°C under nitrogen protection for 72 hours, and mercapto-functionalized graphene was obtained after washing. Soak the s...

Embodiment 3

[0035] Example 3: Preparation of layer-by-layer self-assembled graphene-coated nickel wire solid-phase microextraction fiber

[0036] Include the following steps A and B in turn:

[0037] A. Electroless silver plating on the surface of nickel wire

[0038] After the surface of the nickel wire is polished with fine sandpaper, it is washed with water and ethanol in sequence to remove impurities on the surface and increase the surface area. Put the treated nickel wire into the mixed solution of silver ammonia solution and glucose solution, the molar ratio of silver ammonia ion and glucose is 1:2, the mass concentration of glucose is 15%, and react at room temperature for 0.5 hours.

[0039] B. Preparation of layer-by-layer self-assembled graphene coatings

[0040] Graphene oxide with a mass ratio of 1:5 was reacted with mercaptopropyltriethoxysilane at 90°C under argon protection for 48 hours, and mercapto-functionalized graphene was obtained after washing. Soak the silver-pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com