Production method of high temperature-resistant catalyst carrier material for automobile exhaust purification

A technology for catalyst carrier and exhaust gas purification, which is applied in the direction of catalyst carrier, physical/chemical process catalyst, chemical instrument and method, etc. It can solve the problems of poor high temperature thermal stability, etc., and achieve excellent high temperature specific surface area, excellent high temperature thermal stability, good The effect of the catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Preparation of feed liquid

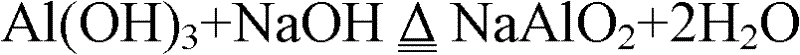

[0029] Add aluminum hydroxide and a sodium hydroxide solution with a mass percentage concentration of 35% into the reaction kettle, stir and heat to boiling, and keep boiling for 40 minutes until the aluminum hydroxide is completely dissolved to obtain a sodium metaaluminate feed liquid, and then Add pure water to adjust the [Al 2 o 3 ] at a concentration of 200g / l, [OH - ] at a concentration of 6.0mol / l, cooled to 35-40°C and then filtered to complete the preparation of the first feed liquid;

[0030] Add nitric acid to the reaction kettle and stir, add pure water to adjust the [H + ] concentration is 3.0mol / l, completes the preparation of the second feed liquid;

[0031] 2) Continuous precipitation

[0032] First add hot pure water at 50-55°C to the overflow position of the reactor, and then control the sodium metaaluminate feed liquid (first feed liquid) and nitric acid feed liquid (second feed liquid) through a metering device. ...

Embodiment 2

[0045] 1) Preparation of feed liquid

[0046] Add aluminum hydroxide and a sodium hydroxide solution with a mass percentage concentration of 32% into the reactor, stir and heat to boiling, and keep boiling for 30 minutes until the aluminum hydroxide is completely dissolved to obtain a sodium metaaluminate feed liquid, and then Add pure water to adjust the [Al 2 o 3 ] concentration of 180g / l, [OH - ] at a concentration of 5.0mol / l, cooled to 20-25°C and then filtered to complete the preparation of the first feed liquid;

[0047] Add nitric acid to the reaction kettle and stir, add pure water to adjust the [H+ ] concentration is 2.5mol / l, completes the preparation of the second feed liquid;

[0048] 2) Continuous precipitation

[0049] First add hot pure water at 45 to 50°C to the overflow position of the reactor, and then control the flow rate ratio of sodium metaaluminate feed liquid and nitric acid feed liquid to 1:2 through a metering device, and the step 1) The sodium ...

Embodiment 3

[0062] 1) Preparation of feed liquid

[0063] Add aluminum hydroxide and a sodium hydroxide solution with a mass percentage concentration of 37% into the reactor, stir and heat to boiling, and keep boiling for 50 minutes until the aluminum hydroxide is completely dissolved to obtain a sodium metaaluminate feed liquid, and then Add pure water to adjust the [Al 2 o 3 ] concentration is 210g / l, [OH - ] at a concentration of 6.5mol / l, cooled to 30-40°C and then filtered to complete the preparation of the first feed liquid;

[0064] Add nitric acid to the reaction kettle and stir, add pure water to adjust the [H + ] The concentration is 3.5mol / l, completes the preparation of the second feed liquid;

[0065] 2) Continuous precipitation

[0066] First add hot pure water at 45-55°C to the overflow position of the reactor, and then control the flow rate ratio of the sodium metaaluminate feed liquid and the nitric acid feed liquid to 1:2 through a metering device. The sodium metaa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com