Automatic machine tool for processing pin hole of main angle steel of middle section of tower crane

A technology of automatic machine tools and intermediate joints, which is applied in the direction of metal processing machinery parts, metal processing, automatic control devices, etc., can solve the problems of insufficient processing accuracy, large mold wear, and high processing costs, and achieve low processing costs. , Efficiency improvement, and the effect of material resource improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

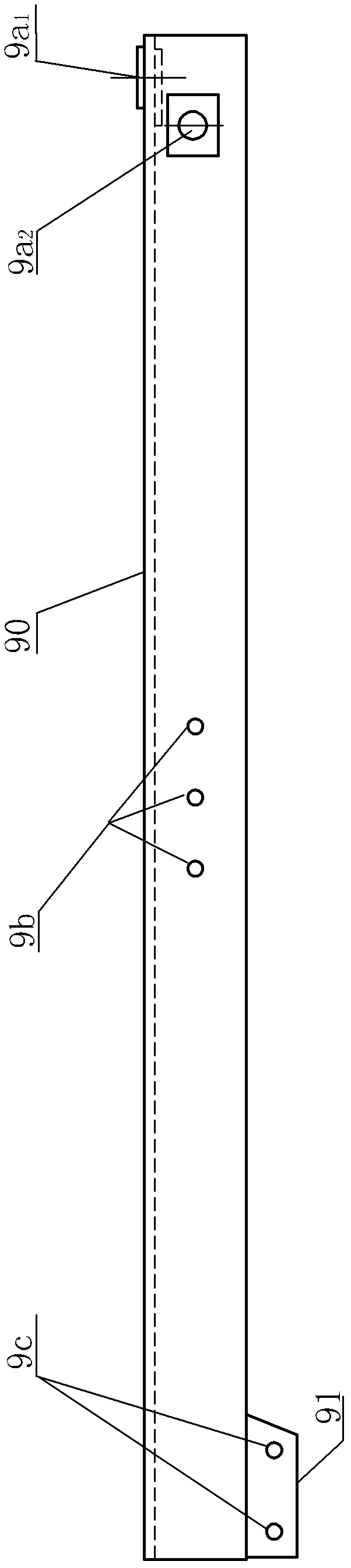

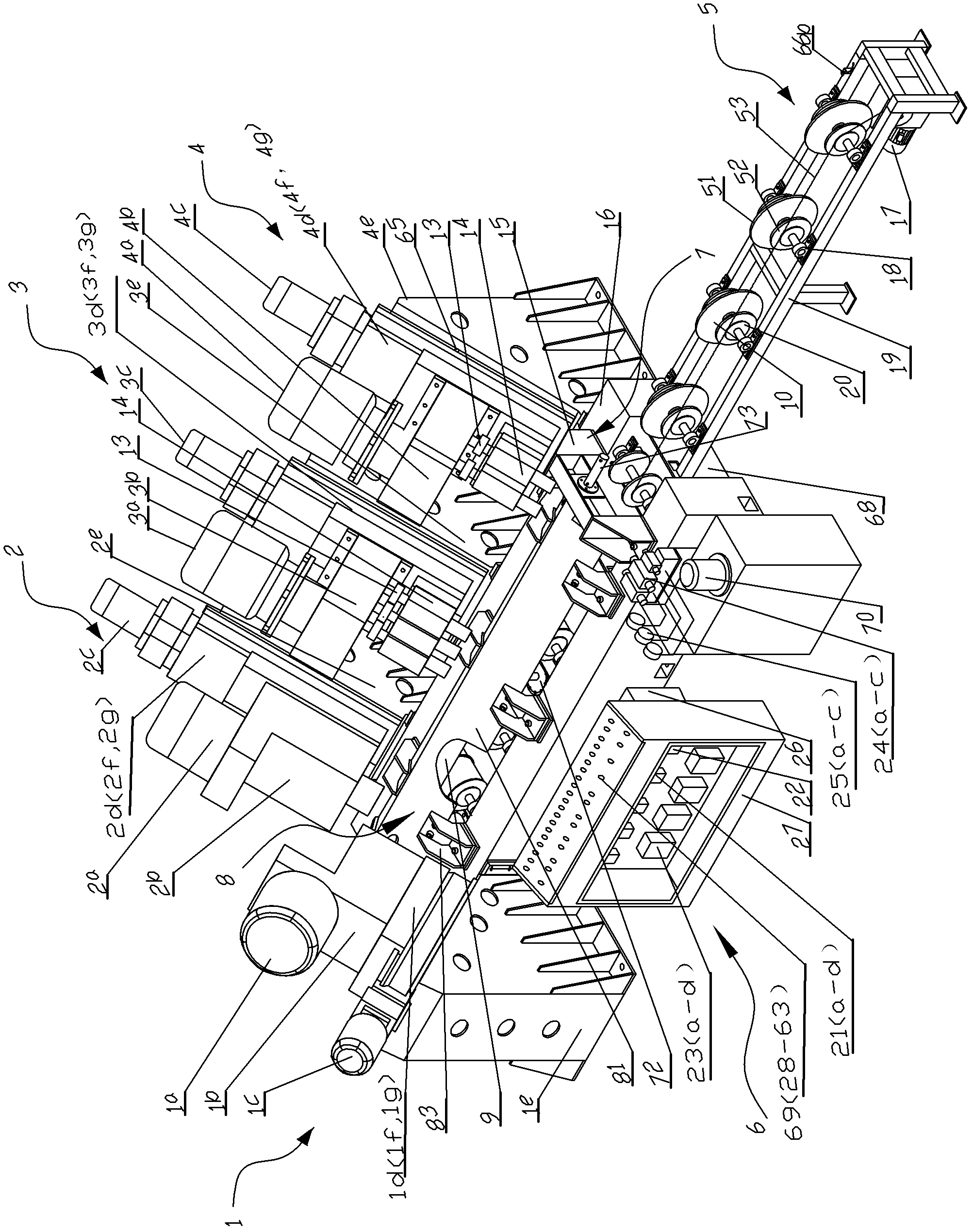

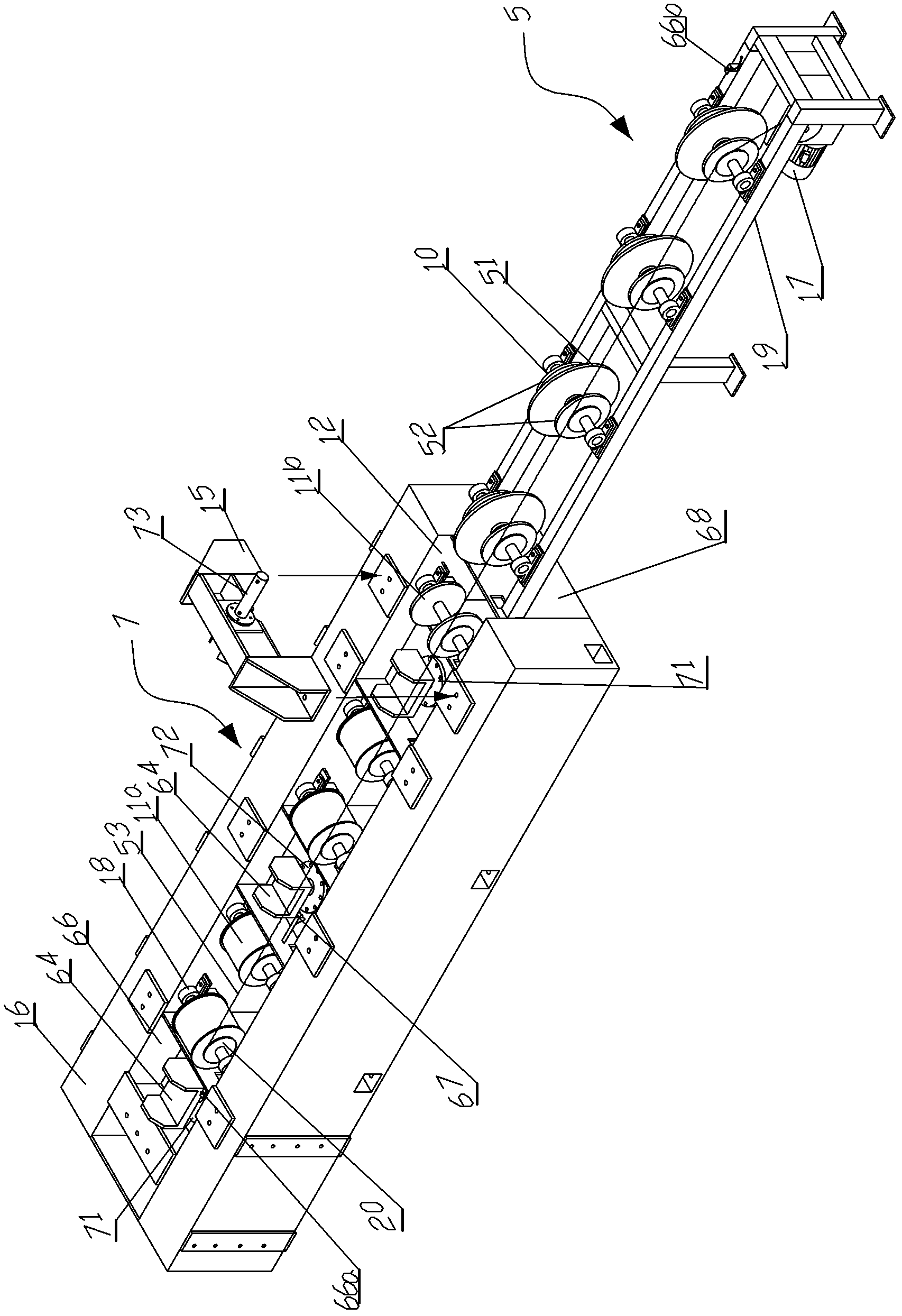

[0025] figure 2 ~Fig. 5 shows an automatic machine tool for processing the steel pin holes of the central section of the tower crane, which is characterized in that it includes a bed 16, a material conveyor belt 5, a positioning mold base 8, a positioning and tensioning device 7, and multiple tools for drilling and boring holes. Four power head devices, four power head devices 1-4 are set in this example, and the control of the start and stop operation of material conveying, positioning and tightening operation, power head device positioning and drilling and boring operation is controlled by the electric actuator Unit 6. The automatic machine tool provided by this embodiment is mainly used for figure 1 The processing of the main steel in the middle section of a typical tower crane is shown.

[0026] The above-mentioned bed 16 is a bar-shaped cuboid with a horizontal through groove along the longitudinal direction, and the above-mentioned material conveyor belt 5 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com