Impeller cutting type vortex air floatation device

A cutting-type, air flotation technology, which is applied in the direction of flotation water/sewage treatment, etc., can solve the problems of wasting coagulation agent, large bubble diameter, and no gas volume adjustment device, so as to improve the efficiency of air flotation concentration, save treatment costs, The effect of saving power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

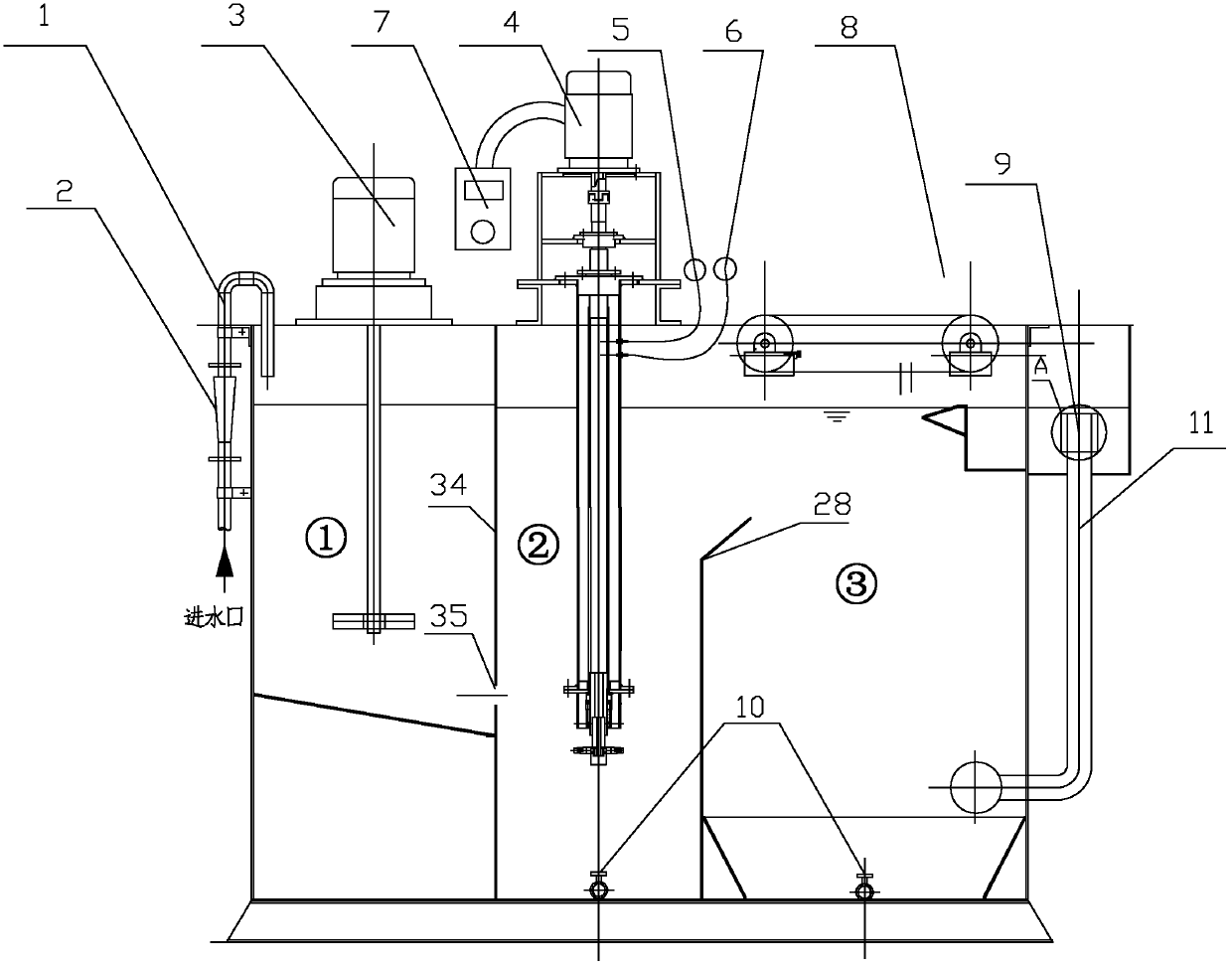

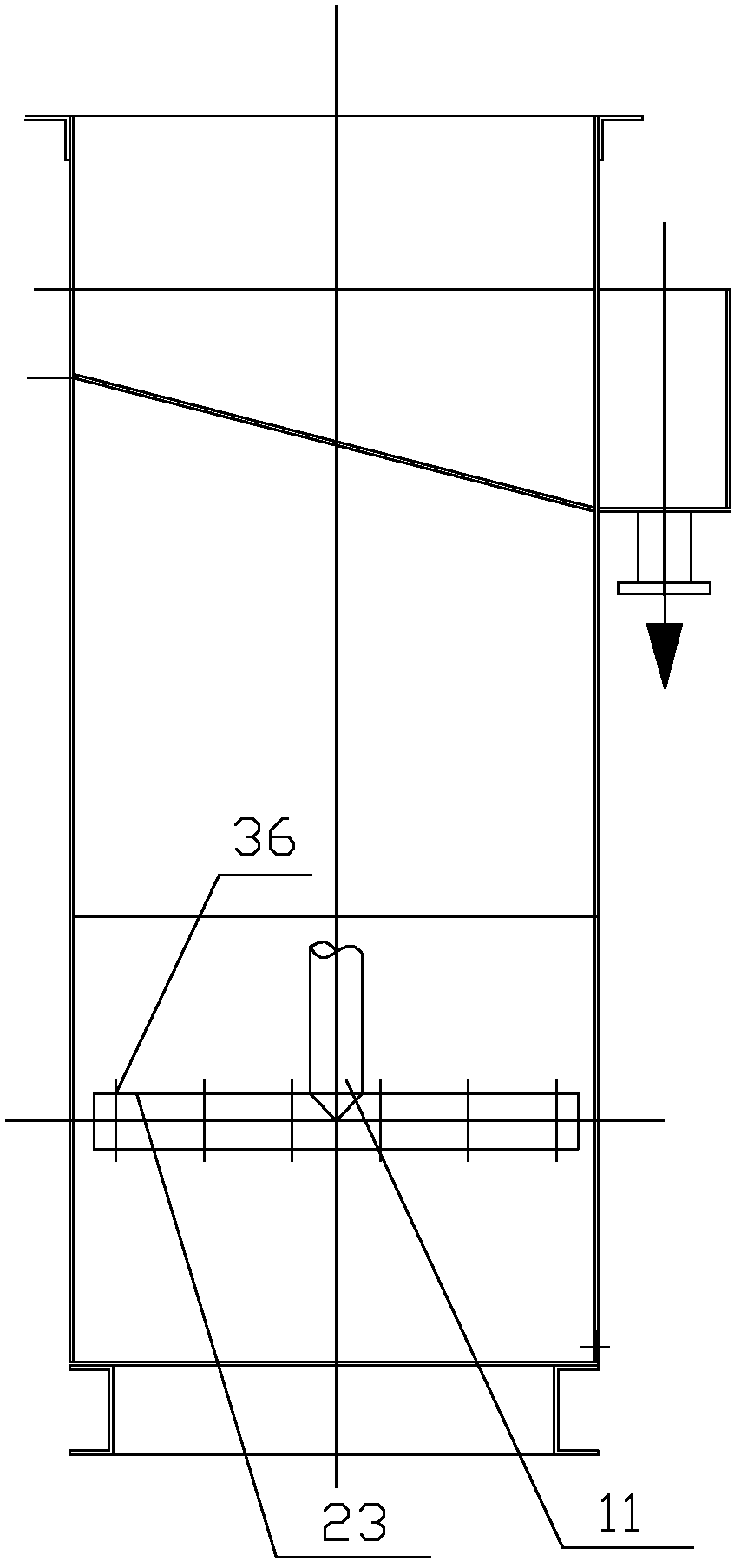

[0026] Such as figure 1 As shown, the reaction tank of the present invention is divided into three parts: dosing mixing area ①, air flotation area ② and separation area ③, wherein the dosing mixing area and the air flotation area are separated by a partition (34), and the air flotation area A deflector (28) is provided between the separation zone and the separation zone;

[0027] The dosing and mixing area ① includes the water inlet pipe (1), the water inlet flowmeter (2) and the dosing mixer (3). The water inlet flowmeter (2) is installed on the water inlet pipe (1) through flange connection, and the dosing mixer (3) is set on the top of the dosing mixing area ① of the reaction tank. There are two flow holes at the bottom of the dosing and mixing area ①, through which the waste water after dosing and coagulation flows into the air flotation area ②.

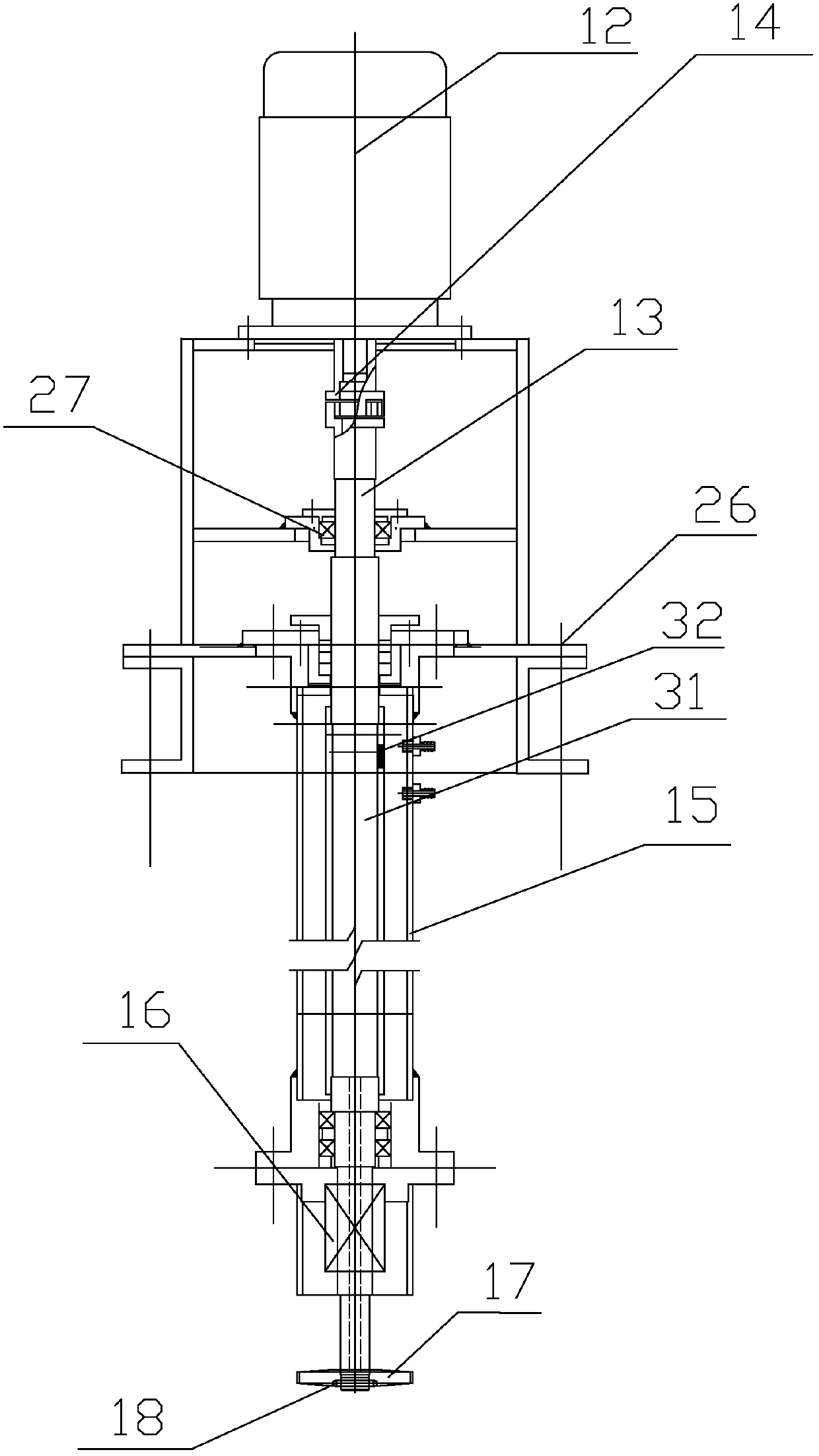

[0028] The air flotation area ② includes a dissolved air generator (4), an adjustable air flow meter (5), and a vacuum gauge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com