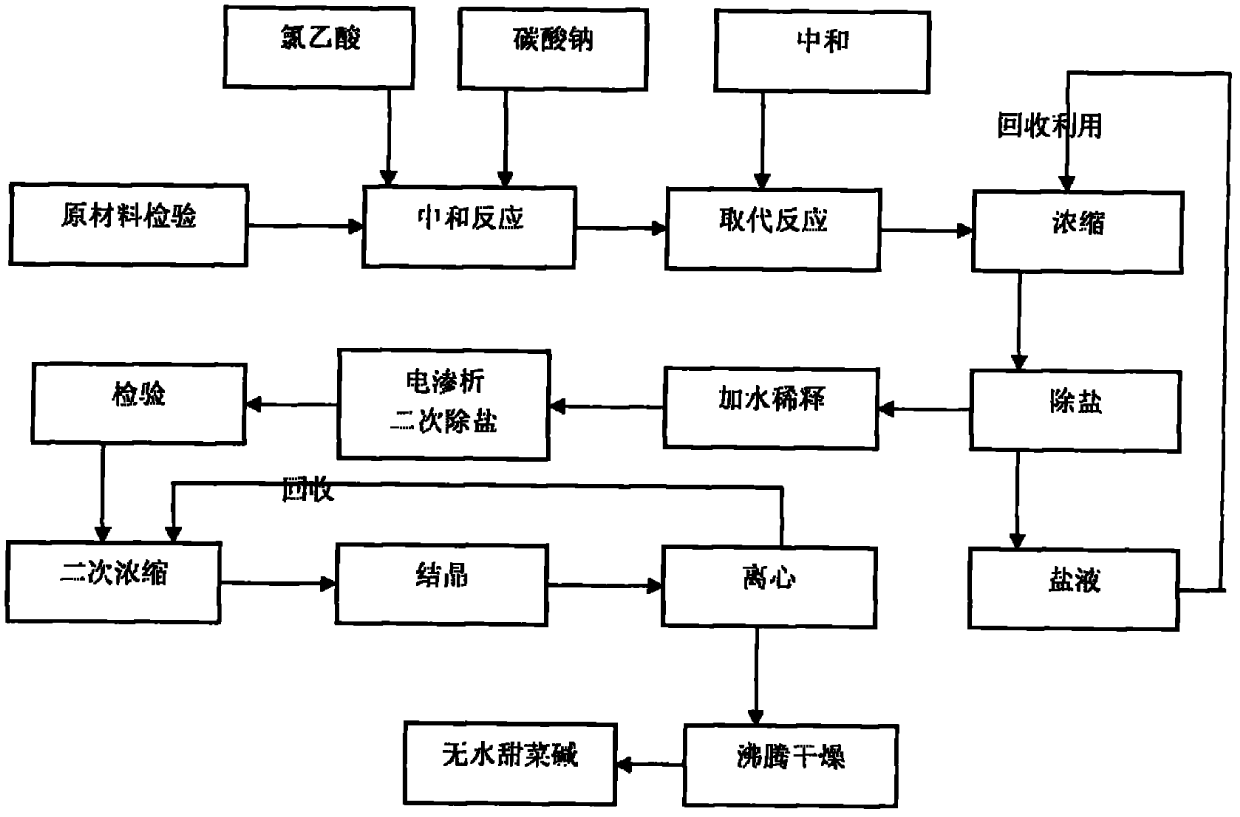

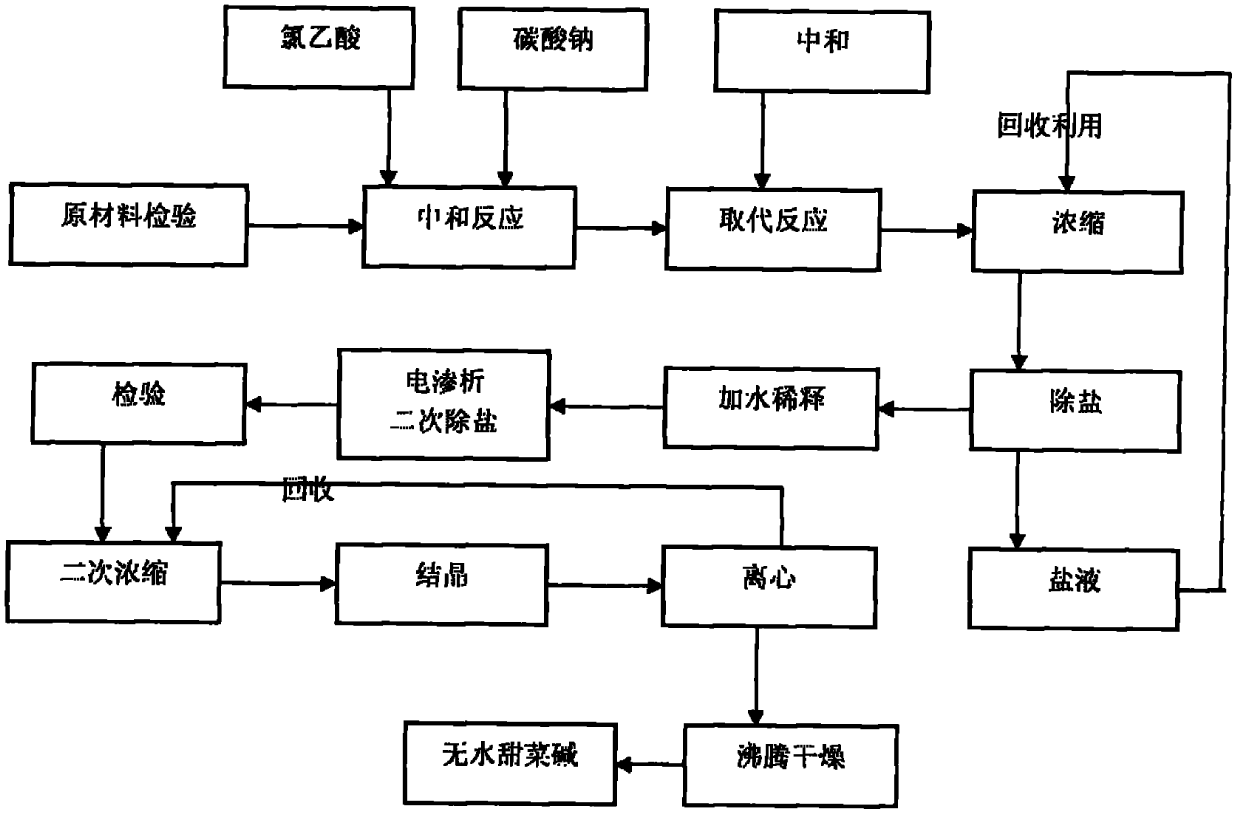

Preparation method of anhydrous betaine

A technology of anhydrous betaine and betaine, which is applied in the preparation of organic compounds, chemical instruments and methods, and cyanide reaction preparation, etc., can solve the problems of large investment, low product purity, and low production capacity, so as to increase production capacity and save energy. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) 2 tons of water, 1.5 tons of chloroacetic acid, and 0.84 tons of sodium carbonate are dropped into the reaction kettle at normal temperature. When feeding materials, pay attention to the feeding speed, so as not to separate out a large amount of carbon dioxide;

[0022] (2) Feed 0.95 tons of trimethylamine after fully reacting. When feeding, the reaction temperature is controlled at 55 ° C. When PH = 7, stop feeding. During the feeding process of trimethylamine, the pressure of the reactor is not allowed to exceed 0.1Mpa. After the amine feed is completed, the temperature is 50°C and the stirring is started, and the temperature is kept for 3 hours, and then the material is moved to the concentrated reaction kettle;

[0023] (3) Keep the steam pressure stable at 0.3MPa, heat the material to concentrate, the vacuum pressure is stabilized at -0.08MPa, stop heating when the material temperature reaches 115°C, stir for 20 minutes, and then move the supernatant to the liqu...

Embodiment 2

[0031] (1) 2 tons of water, 1.5 tons of chloroacetic acid, and 0.84 tons of sodium carbonate are dropped into the reaction kettle at normal temperature. When feeding materials, pay attention to the feeding speed, so as not to separate out a large amount of carbon dioxide;

[0032] (2) Feed 0.95 tons of trimethylamine after fully reacting. When feeding, the reaction temperature is controlled at 65°C. Stop feeding when PH=7. During the feeding process of trimethylamine, the pressure of the reactor is not allowed to exceed 0.1Mpa, trimethylamine After the amine feed is completed, the temperature is 60°C and the stirring is started, and the temperature is kept for 3 hours, and then the material is moved to the concentrated reaction kettle;

[0033] (3) Keep the steam pressure stable at 0.3MPa, heat the material to concentrate, the vacuum pressure is stabilized at -0.08MPa, stop heating when the material temperature reaches 115°C, stir for 20 minutes, and then move the supernatant t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com