Anionic polyacrylamide as well as preparation method and application thereof

A technology of polyacrylamide and acrylamide monomer, which is applied in the field of anionic polyacrylamide and its preparation and application, can solve the problems of low solid content of flocculant, long dissolution time, large usage, etc., and achieve the improvement of relative molecular weight and Solid content, high solid content, the effect of reducing the viscosity of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

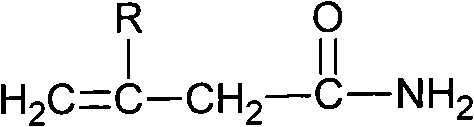

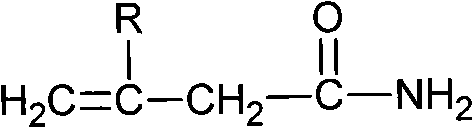

Method used

Image

Examples

Embodiment 1

[0025] (1) first acrylamide monomer and polyethylene oxide dispersant with a relative molecular weight of 50000 are mixed in a mass ratio of 1:2, then water is added to make the content of acrylamide monomer 25%;

[0026] (2) Add anionic monomer acrylic acid with 20% mass of acrylamide monomer and 6% cerium nitrate, and polymerize at 70° C. for 6 hours after adding the medicine.

[0027] The obtained product is kept warm for 24 hours, and the moisture is completely volatilized. After testing, the solid content is 93%, and the relative molecular weight is 25 million, which can be used as a high-efficiency industrial wastewater flocculant. At the same time, the solubility of the product was tested, 2g of the polymer was added into 100g of water, stirred gently, and quickly dissolved into a transparent solution.

Embodiment 2

[0029] (1) First, the acrylamide monomer is mixed with a polyethylene oxide dispersant with a relative molecular weight of 10000 in a mass ratio of 1:0.5, and then water is added to make the content of the acrylamide monomer 10%;

[0030] (2) Add anionic monomer methacrylic acid with 15% mass of acrylamide monomer and 0.8% praseodymium nitrate, and polymerize at 40° C. for 4 hours after adding the medicine.

[0031] The obtained product is kept warm for 24 hours, and the moisture is completely volatilized. After testing, the solid content is 90%, and the relative molecular weight is 18 million, which can be used as a more efficient industrial wastewater flocculant. At the same time, the solubility of the product was tested, 2g of the polymer was added into 100g of water, stirred gently, and quickly dissolved into a transparent solution.

Embodiment 3

[0033] The acrylamide monomer in step (1) is mixed with the polyethylene oxide dispersant with a relative molecular weight of 10000 in a mass ratio of 1:0.5, and then water is added to make the content of the acrylamide monomer 10%. All the other conditions are the same as in Example 1.

[0034] The obtained product is kept warm for 24 hours, and the moisture is completely volatilized. After testing, the solid content is 90%, and the relative molecular weight is 23 million, which can be used as a high-efficiency industrial wastewater flocculant. At the same time, the solubility of the product was tested, 2g of the polymer was added into 100g of water, stirred gently, and quickly dissolved into a transparent solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com