Preparation method and product of epoxy-modified organosilicon insulating, heat-conducting and high-temperature-resistant coating

A high-temperature-resistant coating and epoxy modification technology, applied in the direction of coating, etc., to achieve good adhesion, simple coating process, and easy conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: the preparation method of a kind of epoxy-modified organic silicon insulating heat-conducting high temperature resistant coating provided by the present invention, it comprises the following steps:

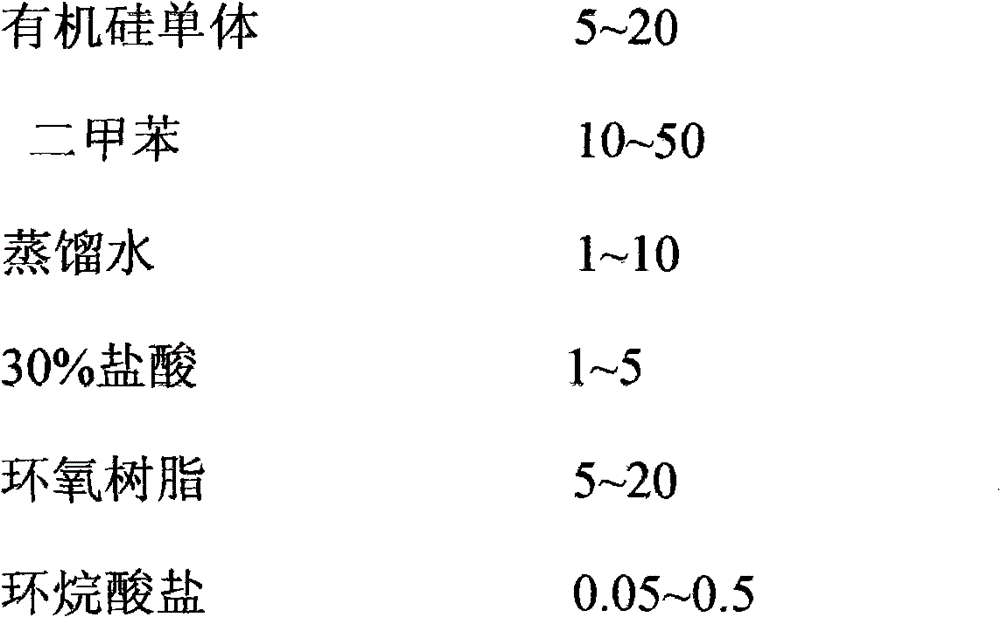

[0034] (1) Preparation of raw materials: Prepare the following raw materials (Kg) according to the following components and weight ratios:

[0035]

[0036] (2) Synthesis of organosilicon prepolymer: Add organosilicon monomer and xylene solvent of equal mass into the reactor, heat to 60-70°C, adjust the pH value to 4-5 with 30% hydrochloric acid, and slowly Add distilled water and react for 2 to 4 hours; after the reaction mixture is allowed to stand for stratification, take the upper layer solution and wash it with water until it is neutral, and distill it under reduced pressure until the solid content rate is 50 to 70% to obtain a silicone prepolymer solution;

[0037] (3) Synthesis of epoxy-modified silicone resin: Mix the silicone prepolymer solution wi...

Embodiment 2

[0051] Embodiment 2: A preparation method and product of an epoxy-modified silicone insulating, heat-conducting, and high-temperature-resistant coating provided by the embodiment of the present invention are basically the same as in Embodiment 1, except that:

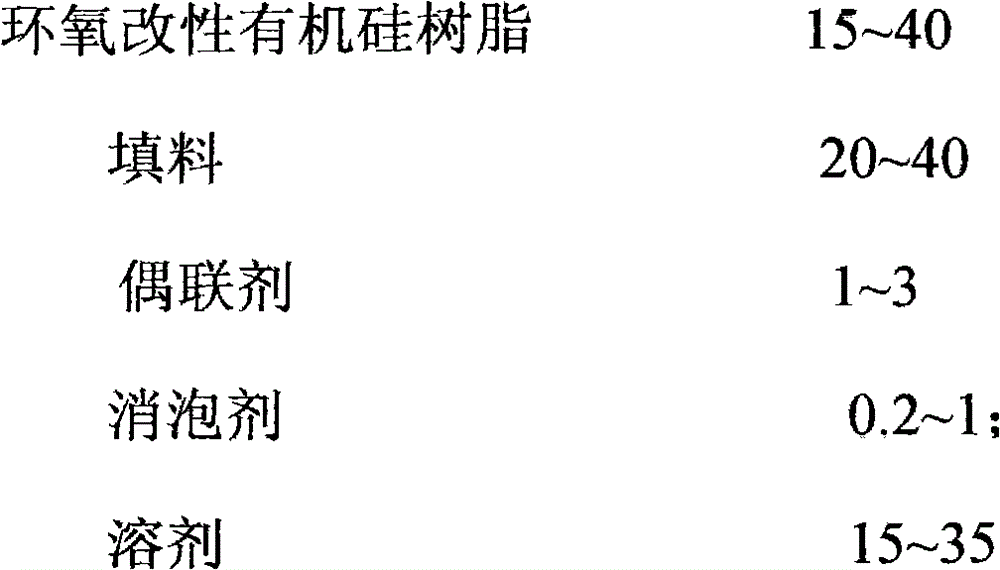

[0052] (1) Preparation of raw materials (Kg)

[0053]

[0054]

[0055] (2) Synthesis of organosilicon prepolymer: Methyltrichlorosilane, dimethyldichlorosilane, phenyltriethoxysilane, dimethyldiethylsilane with a mass ratio of 4:3:9:5 Mix 15kg of oxysilane monomer, add 15kg of xylene solvent with equal mass into the reactor, heat to 65°C, adjust the pH to 4-5 with 30% hydrochloric acid, slowly add 75% of the fully hydrolyzed distilled water under stirring conditions , reacted for 3 hours, the reaction mixture was allowed to stand for stratification, the upper layer solution was washed with water until neutral, and distilled under reduced pressure to a solid content rate of 65% to obtain a silicone prepolymer solu...

Embodiment 3

[0064] Embodiment 3: A preparation method and product of an epoxy-modified silicone insulating heat-conducting and high-temperature-resistant coating provided by the embodiment of the present invention are basically the same as Embodiments 1 and 2, except that:

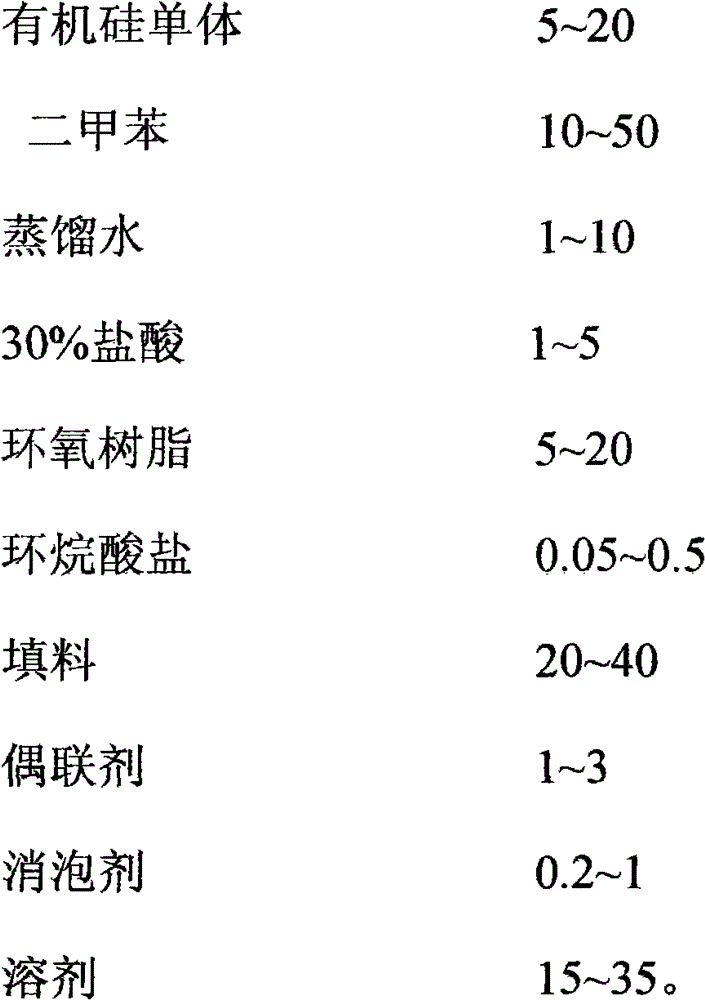

[0065] (1) Preparation of raw materials (Kg)

[0066]

[0067]

[0068] (2) Synthesis of organosilicon prepolymer: Methyltrichlorosilane, dimethyldichlorosilane, phenyltriethoxysilane, dimethyldiethylsilane with a mass ratio of 3:4:8:6 Mix 5 kg of oxysilane monomers, add an equal mass of xylene solvent into the reactor, heat to 60°C, adjust the pH to 4-5 with 30% hydrochloric acid, slowly add 90% of the fully hydrolyzed distilled water under stirring conditions, After reacting for 2 hours, the reaction mixture was left to stand and separated into layers, the upper layer was washed with water until neutral, and distilled under reduced pressure until the solid content rate was 50% to obtain a silicone prepolymer s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com