High-efficiency fireproof corrosionproof paint of steel structure

A technology for anti-corrosion coatings and steel structures, applied in anti-corrosion coatings, fire-resistant coatings, coatings, etc., can solve problems such as micro-smoke, no heat transfer, and non-combustibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

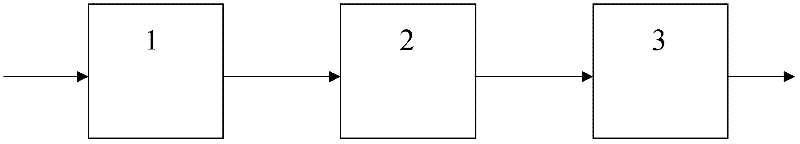

[0023] exist figure 1 Middle: 1 is a high-speed disperser; 2 is a delivery pump; 3 is a sand mill. Anti-corrosion products and flame retardant fire-resistant products are mixed into solvents in different proportions, enter the high-speed dispersion machine tank, and disperse for 45 minutes. , passed the inspection and put into storage; the double anti-coating is applied to the steel structure in one construction; the formula is:

[0024] Type II ammonium polyphosphate 120

[0025] Melamine 80

[0026] Red Dan Powder 15

[0028] Coking benzene 35

[0029] Sodium tripolyphosphate 100

[0030] Titanium dioxide 20

[0031] 582-A resin 200

[0034] Cyclohexanone 6

[0035] Bentonite 10

[0036] Wollastonite powder 40

[0037] Chlorinated Paraffin 20

[0038] Dicyanamide 60

[0039] 200# solvent oil 200

[0040] All the above raw materials are in kilograms.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com